Joist frame for laying floor

A technology of dragon skeleton and floor, applied in the field of dragon skeleton, can solve the problems of lack of expansion space, unsteady fixation, and deformation of floor quality, and achieve the effect of avoiding local warping, improving construction efficiency, and reducing construction noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

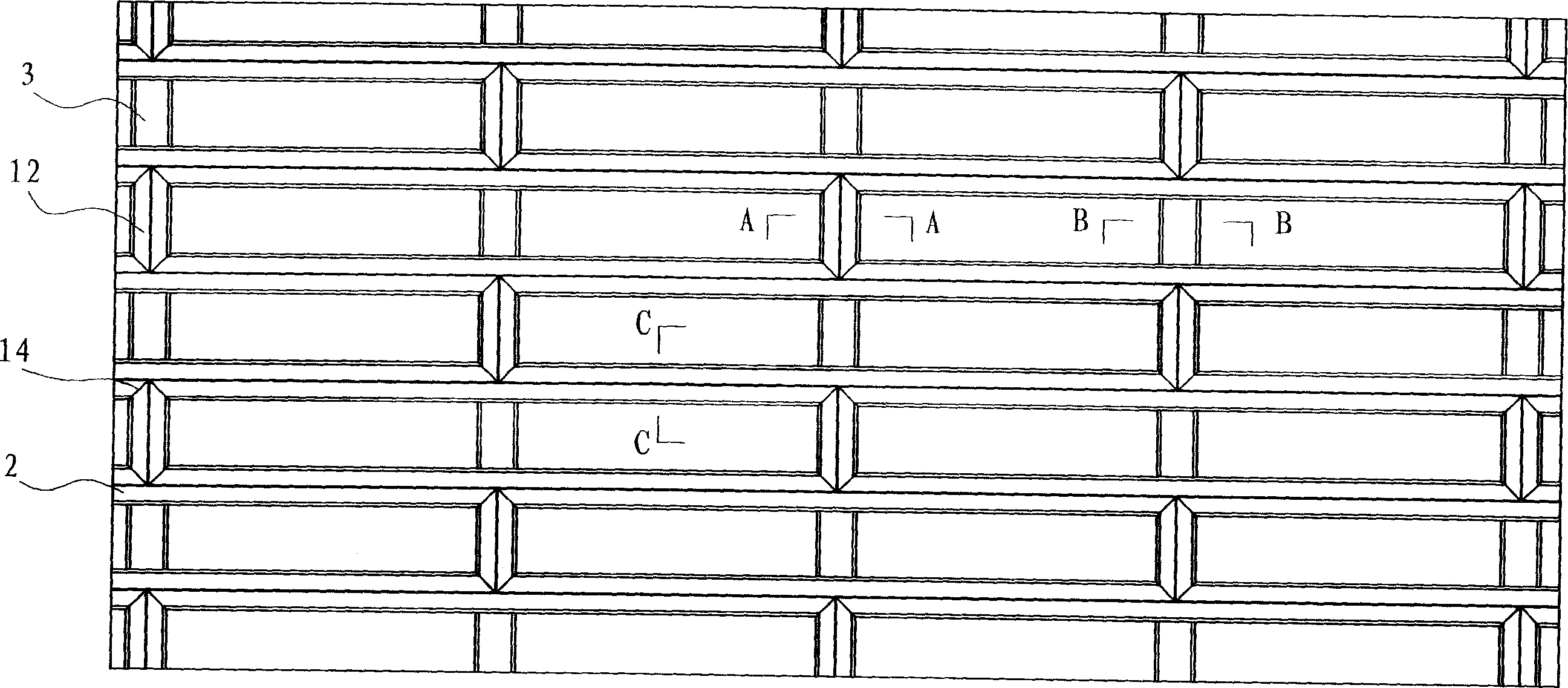

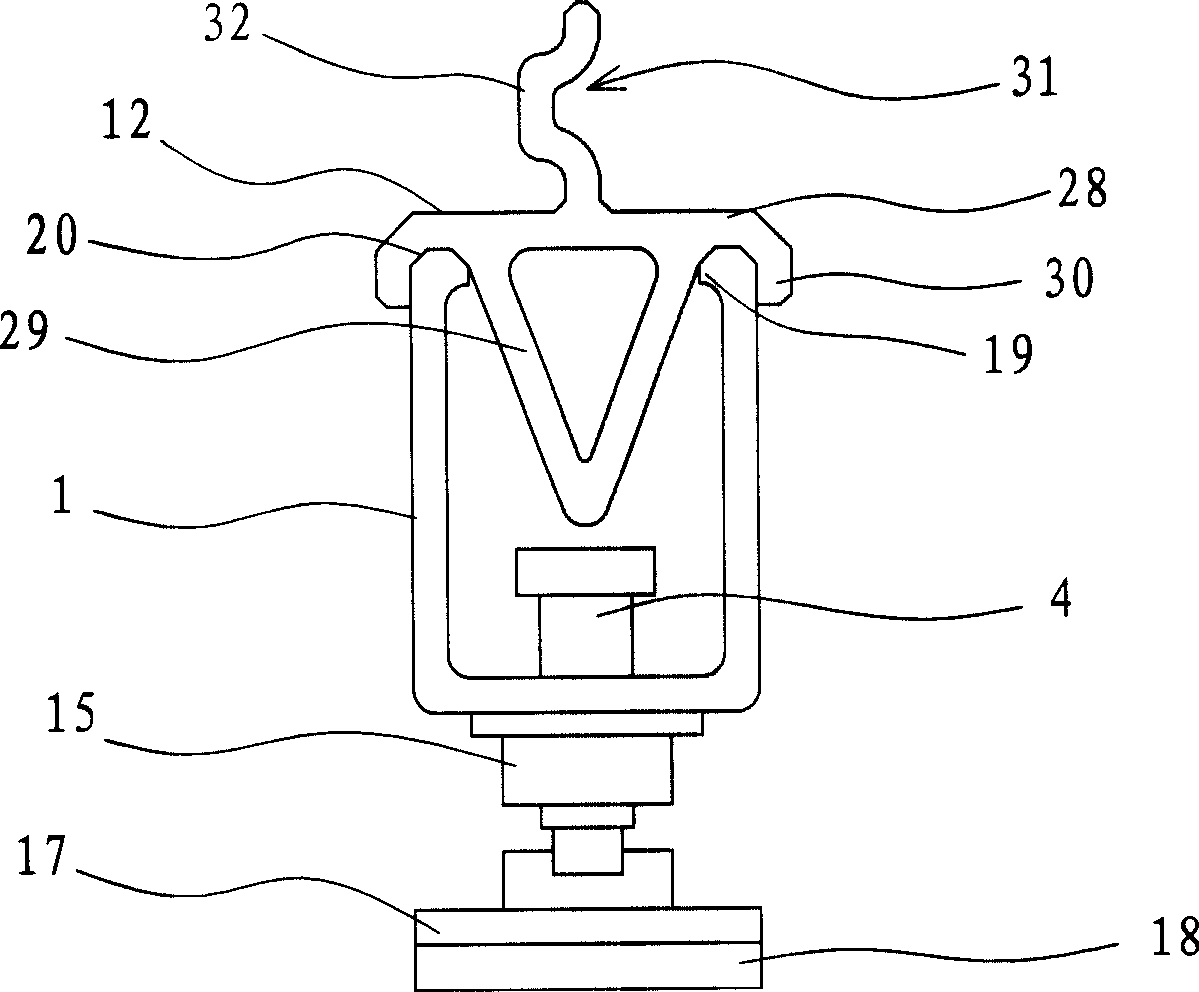

[0031] Embodiment one: see attached figure 1 to attach Figure 7As shown, a keel frame for laying floors includes a plurality of longitudinally arranged main keels 1, and multiple transverse keels 2 respectively bridged on each main keel to form a frame structure; the main keels 1 are open upward profile, the bottom of which is fixedly connected with a foot assembly every 50 cm, the level adjustment mechanism in the foot assembly is composed of an adjustment piece 4 and a fastener 15, and the fastener is fixedly connected to the main keel 1 On the bottom surface, the fastener 15 is provided with a through screw hole corresponding to the opening position on the bottom surface of the main keel, and the adjustment member is a screw that matches the screw hole. figure 2 , 3 As shown, the fastener 15 is composed of a gasket 16 and a fixing nut 22 fixed on the bottom surface of the gasket and matched with the adjustment member. The gaskets on both sides of the fixing nut are resp...

Embodiment 2

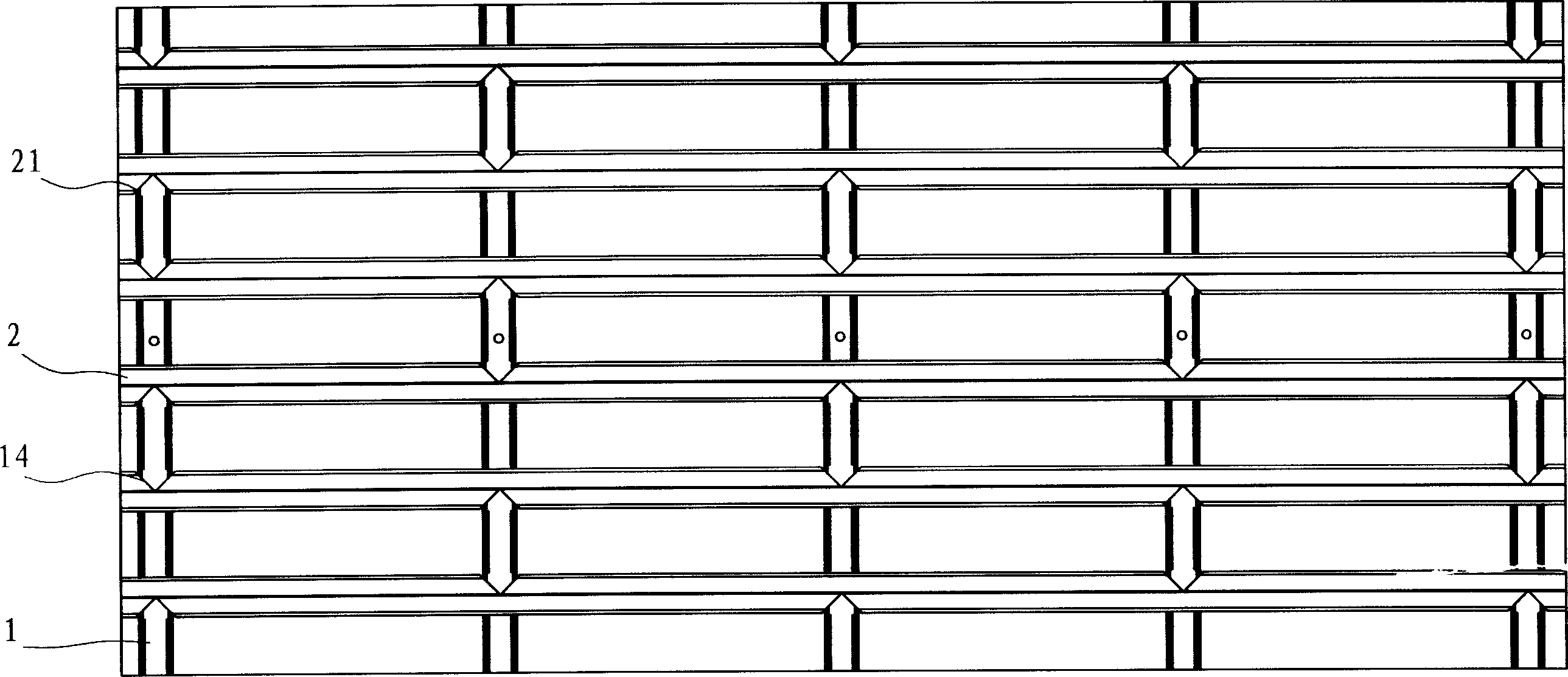

[0033] Embodiment two: see attached Figure 8 As shown, a keel frame for laying floors includes a plurality of longitudinally arranged main keels, the distance between each main keel is 1 / 2 of the length of the floor to be laid, and multiple horizontal keels respectively spanning the main keels. Keel 2, the distance between adjacent horizontal keels is the width of 3 floors, forming a frame structure; the main keel is a profile with an opening upward, and its bottom is fixedly connected with a foot assembly every 80 cm. The foot assembly includes a base and a horizontal adjustment mechanism. The horizontal adjustment mechanism is composed of an adjustment piece and a fastener. The fastener is fixedly connected to the bottom surface of the main keel 1. There is a through screw hole, the adjusting part is a screw matched with the screw hole, the base of the anchor assembly is composed of a metal seat and a buffer pad, and the top of the metal seat is provided with a matching con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com