Intelligent comprehensive pre-fabricating pipe gallery and construction technique thereof

A construction technology and intelligent technology, applied in the field of intelligent comprehensive prefabricated pipe gallery and its construction technology, can solve problems such as difficult control of construction quality, reduce the impact on the life of surrounding residents, save construction time and cost, and reduce construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

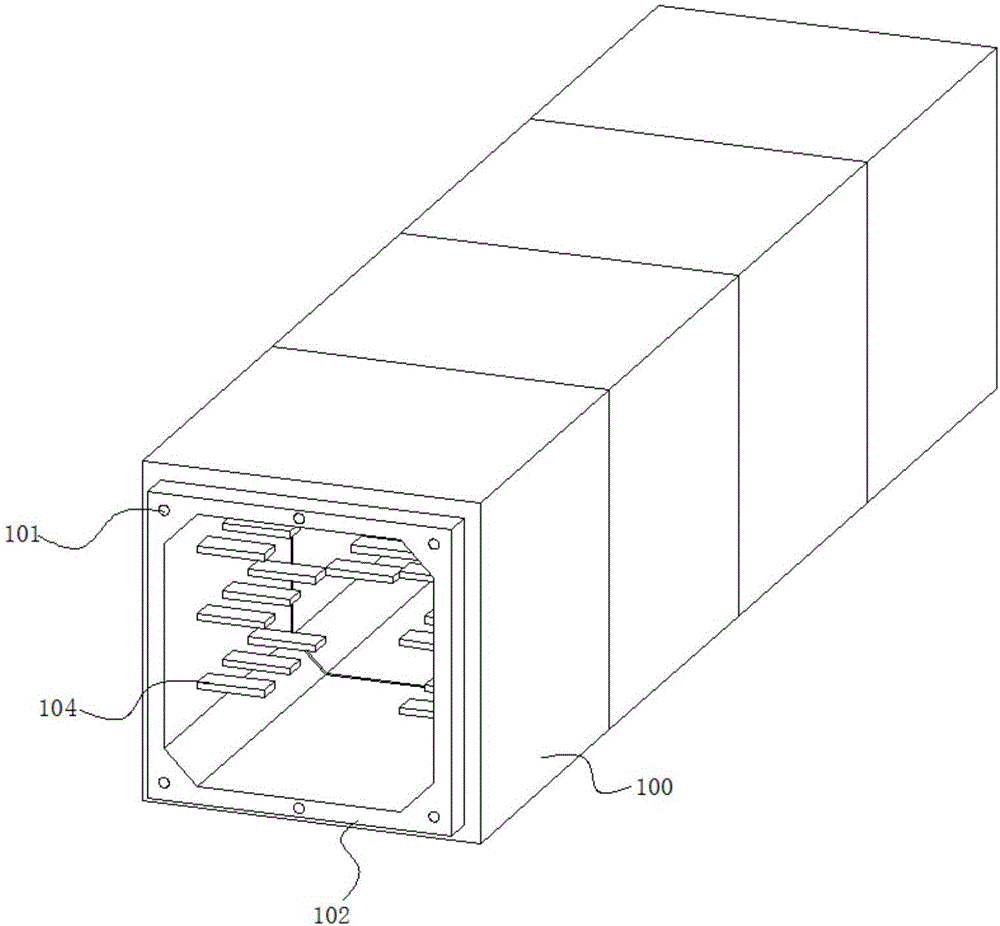

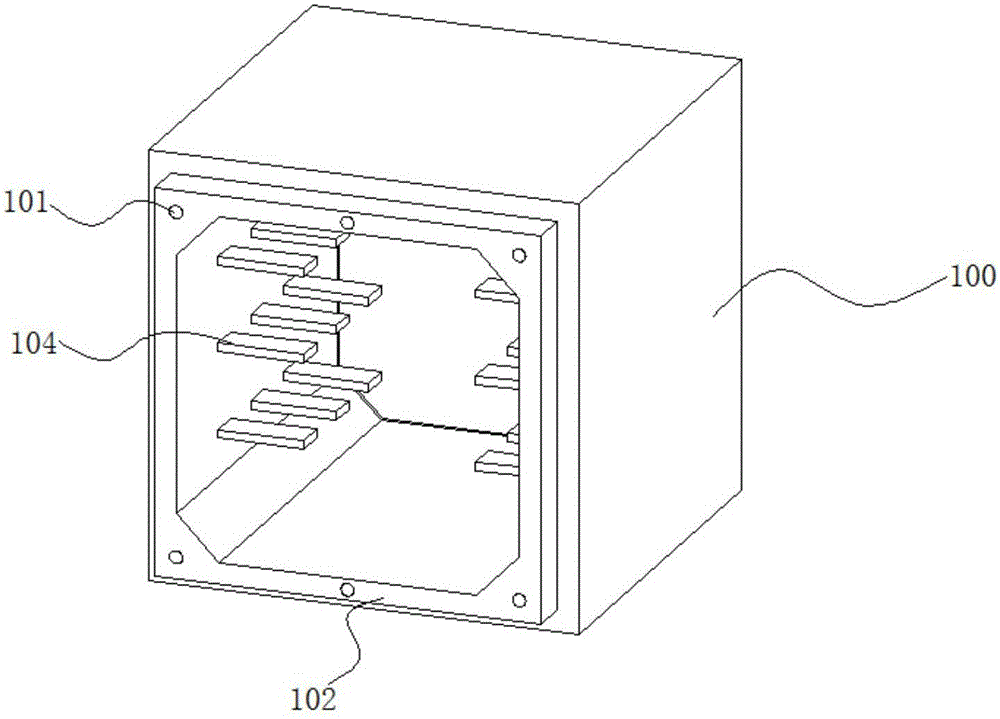

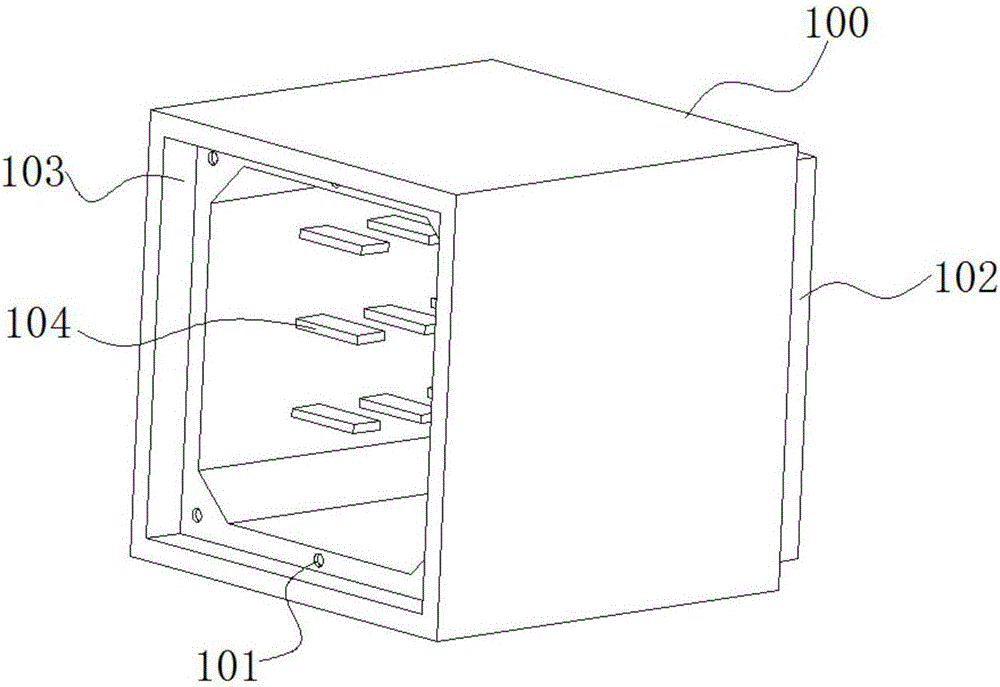

[0035] figure 1 Schematic diagram of the structure of the intelligent comprehensive prefabricated pipe gallery provided by Embodiment 1 of the present invention; figure 2 for figure 1 The schematic diagram of the structure of the prefabricated square culvert shown in the single warehouse; image 3 for figure 1 The structural schematic diagram of another angle of the single warehouse prefabricated square culvert shown; Figure 1-3 As shown, the intelligent comprehensive prefabricated pipe gallery provided by Embodiment 1 of the present invention includes a plurality of tubular single-compartment prefabricated square culverts 100, and the inner wall of the single-compartment prefabricated square culvert 100 is provided with single-compartment connecting holes 101, and the single-compartment connecting holes 101 is arranged along the axial direction of the single-compartment prefabricated square culvert 100, and multiple single-compartment prefabricated square culverts 100 ar...

Embodiment 2

[0048] The embodiment of the present invention is an improvement on the basis of embodiment 1, and the technical solution described in embodiment 1 also belongs to this embodiment, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the intelligent comprehensive prefabricated pipe gallery provided in Embodiment 1 is made of single-chamber prefabricated square culverts, and the intelligent comprehensive prefabricated pipe gallery provided in this embodiment is made of double-chamber prefabricated square culverts , Figure 4 Schematic diagram of the structure of the double warehouse prefabricated square culvert used in the intelligent comprehensive prefabricated pipe gallery provided by Embodiment 2 of the present invention; Figure 5 for Figure 4 The schematic diagram of the structure of the double warehouse prefabricated square culvert shown in another angle; Figure 4 and Figure 5 As shown, the double-compartment prefabricated s...

Embodiment 3

[0056] Image 6 The flow chart of the construction method of the intelligent comprehensive prefabricated pipe gallery provided by Embodiment 3 of the present invention, such as Image 6 As shown, the present embodiment provides the construction technology of the urban underground prefabricated pipe gallery provided by the above-mentioned embodiment 1 and embodiment 2, including the following steps: connecting a plurality of prefabricated square culverts sequentially, and making the connection of the plurality of prefabricated square culverts The holes are one-to-one correspondence, and the connecting pieces are inserted in the multiple connecting holes in sequence, and the tensioning of the connecting pieces makes the multiple prefabricated square culverts closely fit in sequence, and an intelligent comprehensive prefabricated pipe gallery is formed.

[0057] The construction technology of the intelligent comprehensive prefabricated pipe gallery provided by the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com