Modular prefabricated spliced undercrossing tunnel and splicing structure thereof

A prefabricated and modular technology, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of on-site construction waste, high noise of cast-in-place construction, long construction time, etc., and achieve low comprehensive construction cost. , The effect of short road occupation time and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

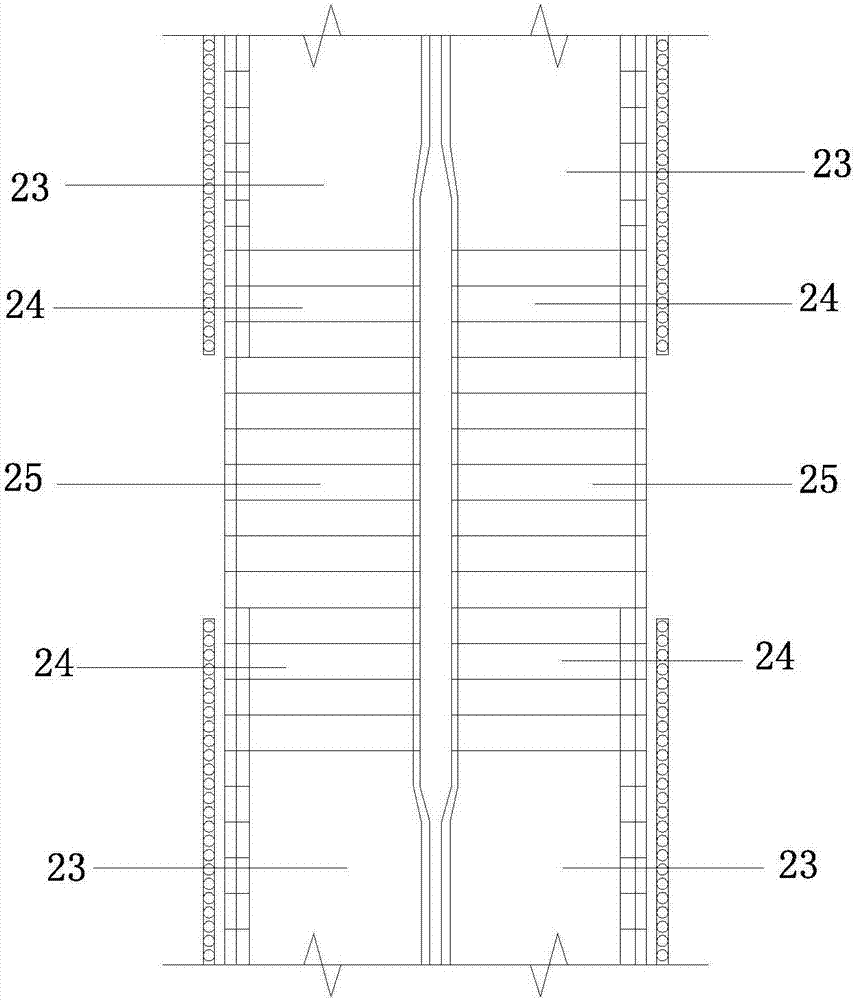

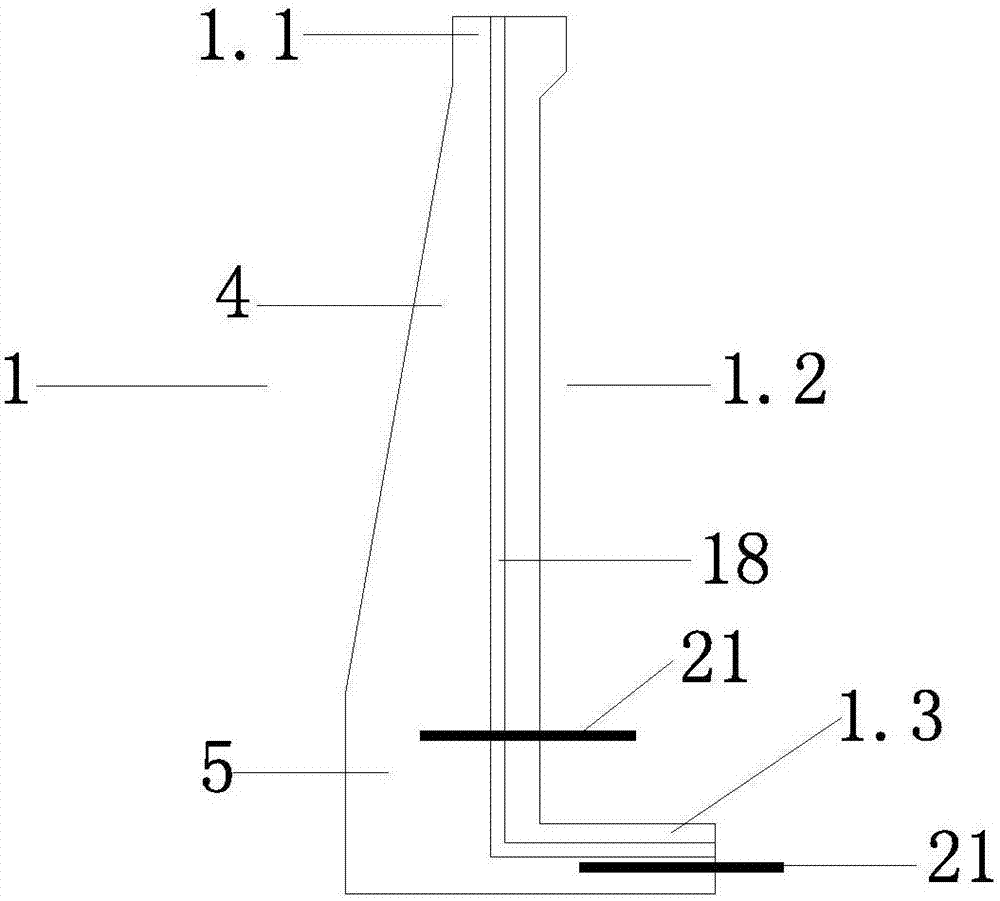

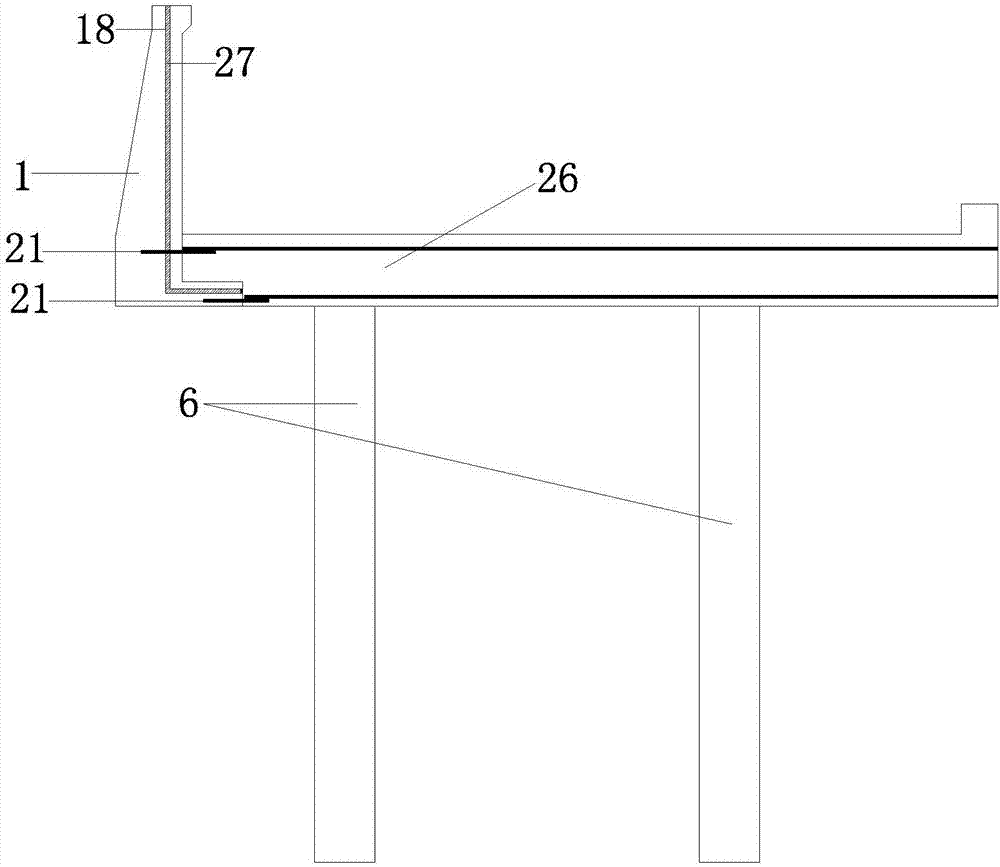

[0034] Such as figure 1 The underpass tunnel shown is composed of a shallow tunnel section 23 , a deep tunnel section 24 and a tunnel frame section 25 . The shallow channel section 23 of the tunnel is composed of prefabricated joints and cast-in-place floor 26 of the shallow channel section of the tunnel, the deep channel section 24 of the tunnel is composed of prefabricated splices of The frame section is composed of prefabricated splicing pieces and cast-in-place base plate 26; as figure 2 As shown in -3, the prefabricated joint of the shallow channel section of the tunnel includes a plurality of prefabricated side panels 1 arranged along the length direction of the tunnel. Such as Figure 4 As shown in -7, the prefabricated splicing piece of the tunnel deep channel section includes a plurality of deep channel section splicing u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com