Construction method for preventing static-pressure precast tubular piles from floating

A technology of prefabricated pipe piles and construction methods, applied in sheet pile walls, foundation structure engineering, construction and other directions, can solve the problems such as the decrease of the ultimate bearing capacity of the piles, the damage of the pile body structure, and the pulling cracks of the pile body, so as to achieve low construction noise, Improved bearing capacity and good pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

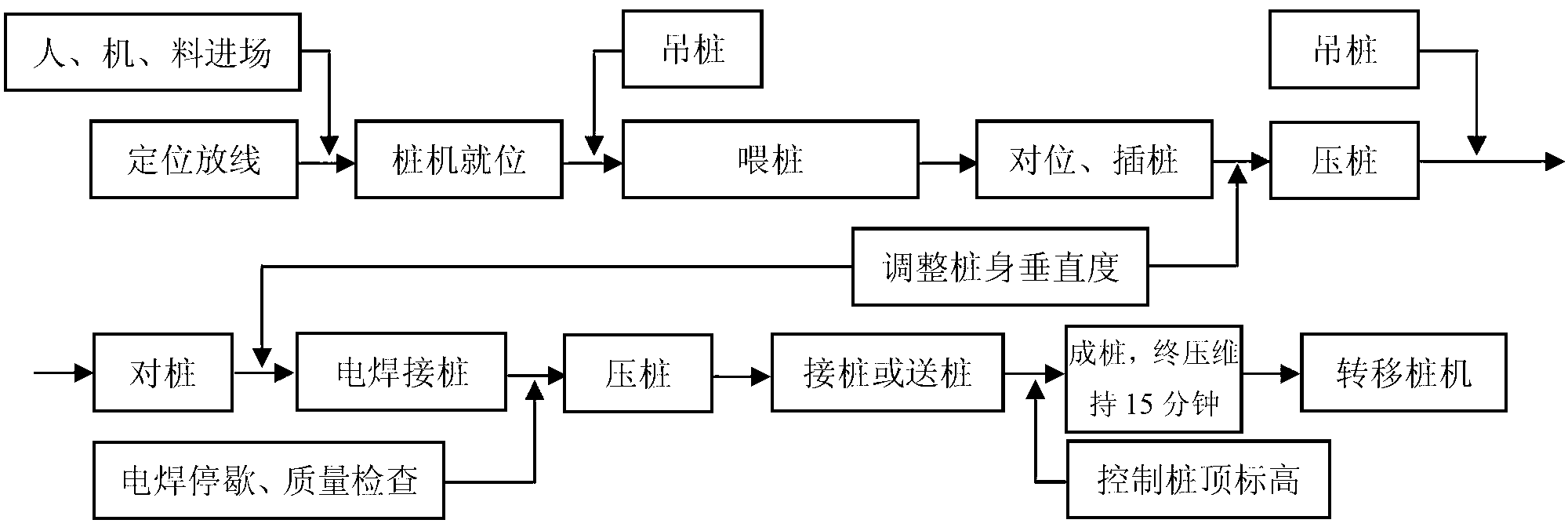

[0027] The construction technological process of the present invention is as figure 1 shown. It mainly includes the steps of positioning and setting out, placing the pile driver in place, inserting piles, pressing piles, connecting piles, sending piles or cutting piles, and forming piles.

[0028] The specific construction method and operation points are as follows:

[0029] (1) Measurement, positioning and setting out

[0030]1) Carefully review the design drawings and the design institute's pile delivery points, and if necessary, arrange the coordinate control points and level control points on the construction site according to the standard setting requirements. The number of standard control points can meet the construction needs and the mutual review between measurement points , and then accurately calculate the dimensional relationship or the coordinates of each pile position according to the design drawings, and accurately measure and place the pile positions.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com