Manufacture method for concrete irregular fender post

A technology for retaining piles and concrete, which is used in manufacturing tools, reinforcement molding, ceramic molding machines, etc., can solve the problems of unsuitable control of fine seams between piles, poor integrity, and large displacement, and achieve good overall structural stability and soil retention. Good waterproof effect and good shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

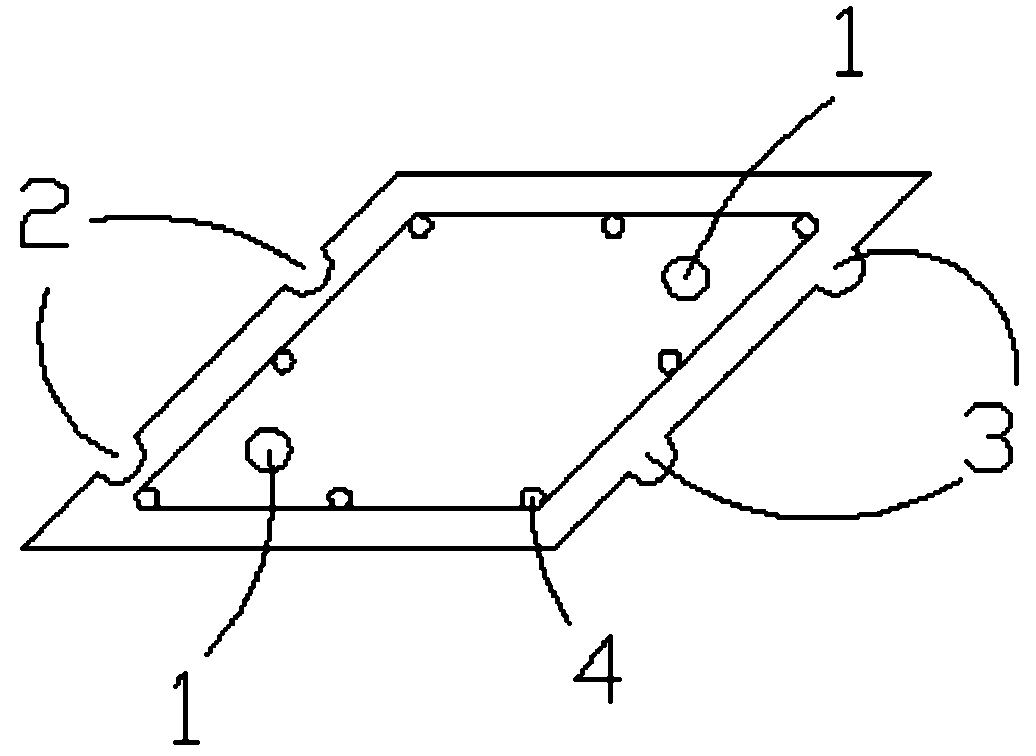

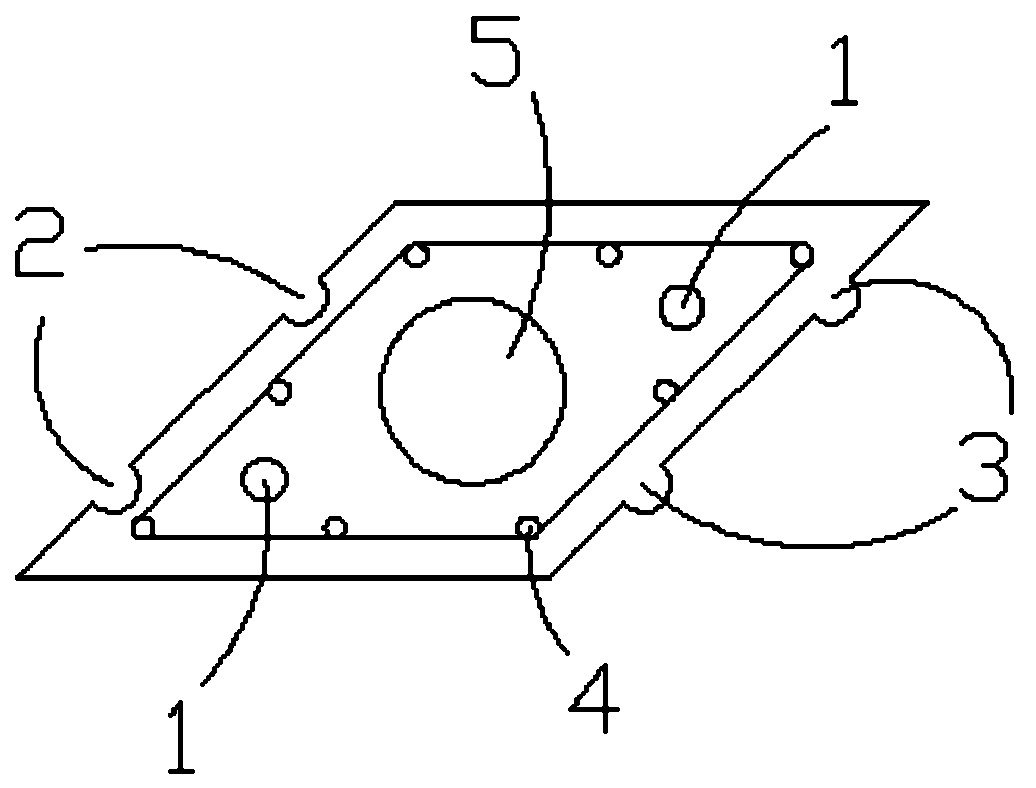

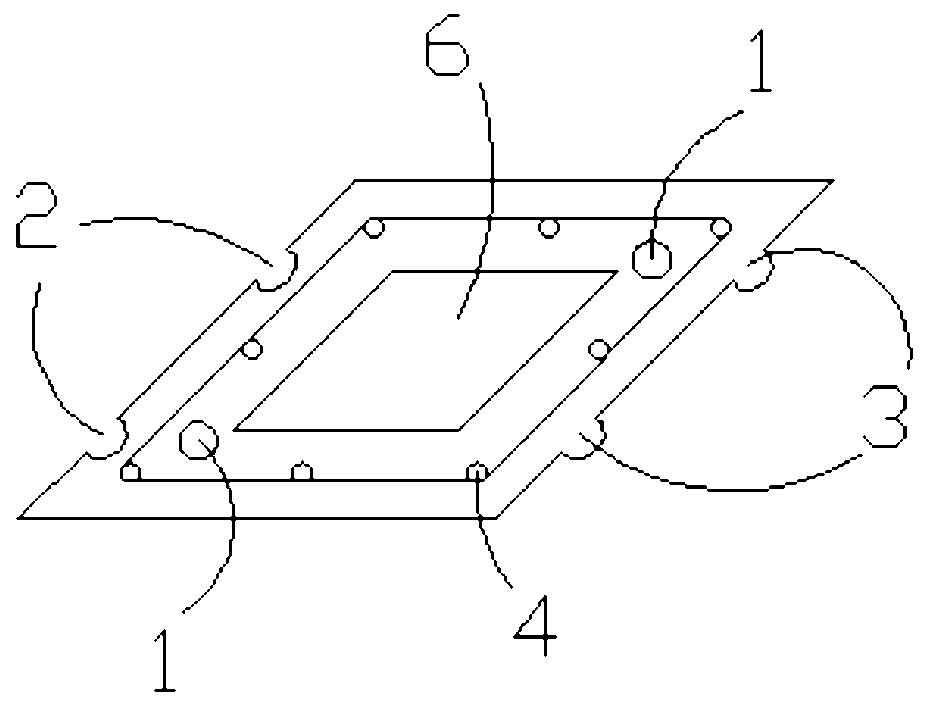

[0047] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0048] In order to have a clearer understanding of the purpose and effect of the present invention, the specific implementation method of the present invention will now be described with reference to the accompanying drawings.

[0049] For piles whose inner hollow is circular, the preparation method is as follows:

[0050] (1), prepare steel cage skeleton;

[0051] (2), prepare a matching centrifugal mold, and apply isolation lubricant in the mold;

[0052] (3), install the prepared reinforcement cage on the mold and tighten the tensioning device;

[0053] (4) Prepare high-performance concrete and feed it into the steel mold, pre-tension the steel bars according to the bending resistance and other properties of the product, and lock and anchor after reaching the required value; for tho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com