High-strength and vibration-free self-compacting concrete prepared from machine-made sand

A technology of concrete and machine-made sand, which is applied in the field of machine-made sand with high-strength, vibration-free self-compacting concrete, and high-strength concrete. It can solve the problems of high-strength concrete such as easy bleeding, segregation, and sensitivity to admixtures, and achieve superior performance and good fluidity. , the effect of reducing the amount of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

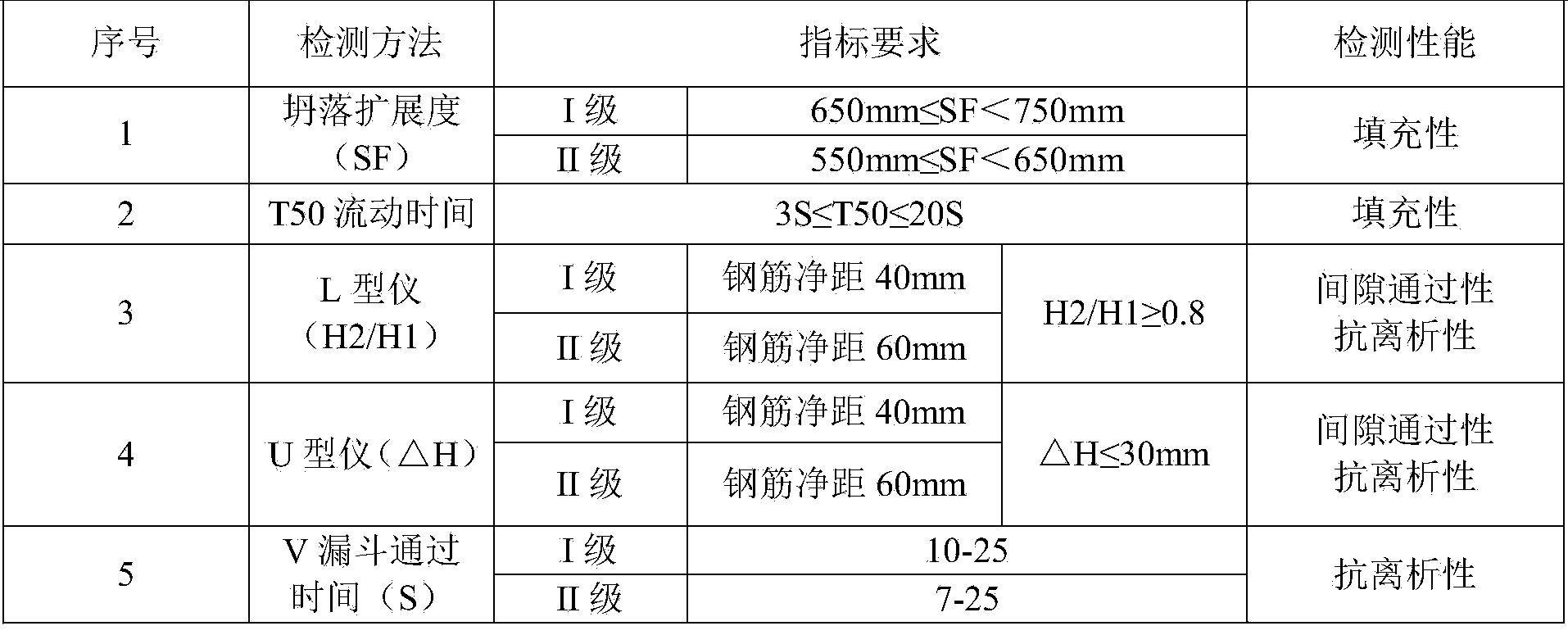

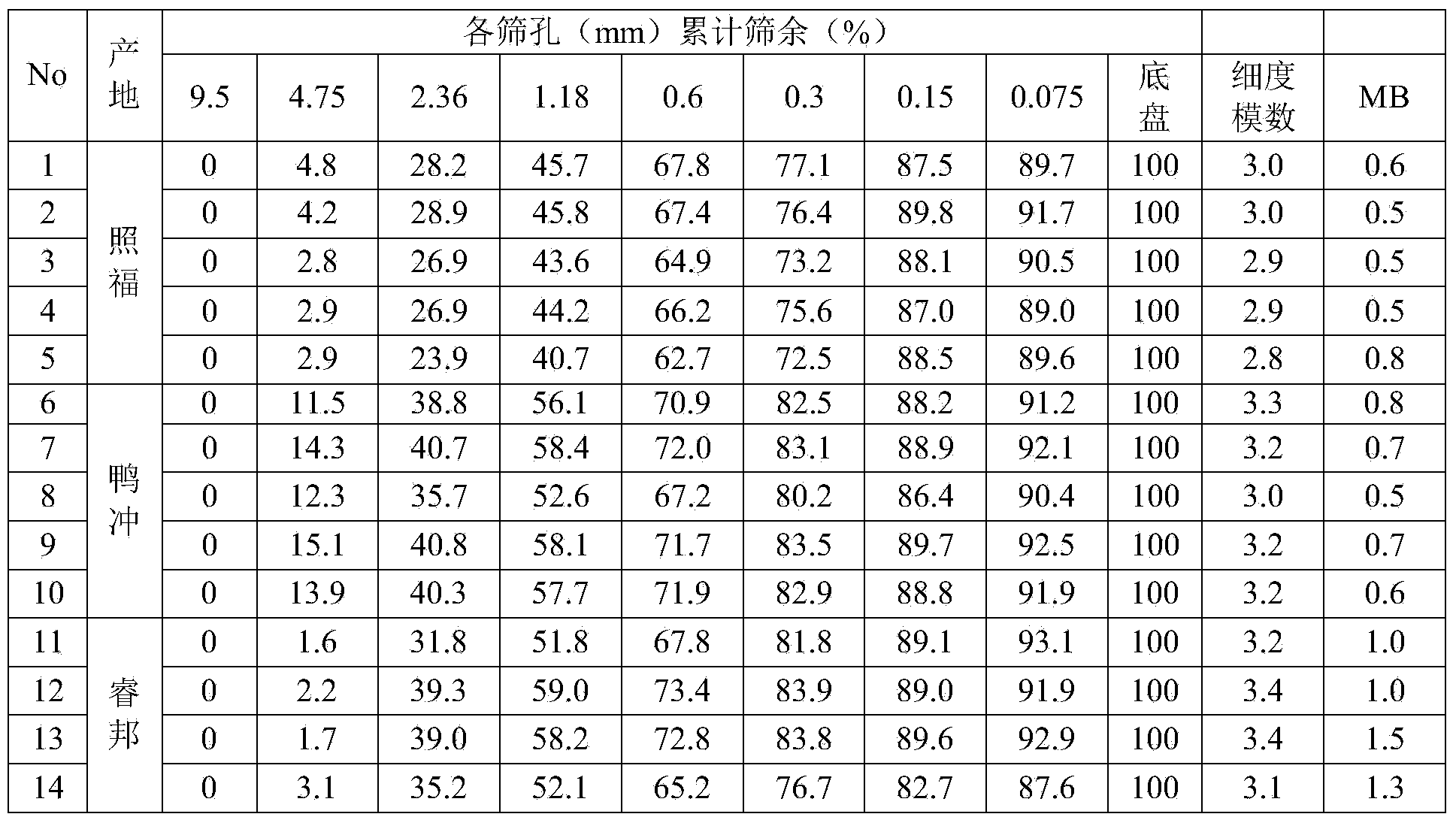

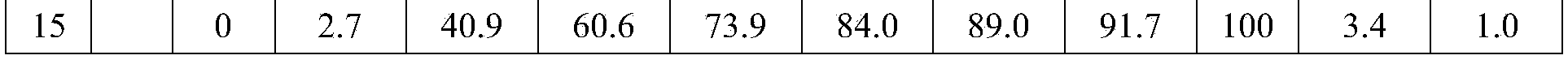

[0075] Screening and testing of machine-made sand raw materials (analysis of machine-made sand characteristics)

[0076] Since the lithology and physical and mechanical properties of sand-making mother rocks vary widely, and the processes and equipment of each sand factory also have similarities and differences, resulting in differences in the indicators of the produced sand. The following 15 sand samples are random sampling. From the test results and pictures It can be seen that the sand gradation produced by the vertical cone crushing process of dolomite parent rock is basically close to the requirements of the sand in Zone II of JGJ52-2006, with good particle fullness, stone powder content of about 10.0%, and small porosity. The dolomitic moderately weathered parent rock produced by the hammer crushing process has a large diameter, the particles on the 0.63mm sieve exceed the standard curve, the particles are more needle-like, and the stone powder content is about 8.5%. Lim...

Embodiment 2

[0081] Study on the effect of different machine-made sand and its stone powder on the performance of concrete

[0082] Combined with the test results of Zhaofu, Yachong and Ruibang sand, the influence of different rocks to produce machine-made sand and the stone powder produced in the production process on the workability and strength of C60 pumped concrete was compared. Compared with natural sand, the machine-made sand particles Rough, angular, and poor gradation. In addition, the higher the content of stone powder in the machine-made sand, the lower the fluidity of its mortar. In order to improve the reduction of fluidity caused by the content of stone powder, the concrete prepared in the test is made of polycarboxylate with high performance. Water reducer, related parameters are shown in Table 3. The influence of test machine-made sand on the workability and strength of C60 pumped concrete.

[0083] table 3

[0084]

[0085]

[0086]It can be seen from Table 3 that ...

Embodiment 5

[0089] Determine the water-binder ratio and the composition of the cementitious material

[0090] Admixtures are one of the indispensable components of high-performance concrete. Using their physical effects and filling effects can not only improve the workability of fresh concrete, but also improve the durability of hardened concrete. The admixture can greatly reduce the micro-cracks inside the concrete due to temperature and shrinkage stress, and improve the compactness and impermeability of the concrete. In this project, Class II F fly ash, S95 class granulated blast furnace slag and silica Ash as an admixture.

[0091] According to the principle of mix ratio design, the water consumption is initially selected as 150kg, the water-binder ratio is 0.23, 0.24, and 0.25 respectively, the tentative sand ratio is 50%, and the concrete bulk density is assumed to be 2520kg / m3. and workability, the test data, workability and strength are shown in Table 4.

[0092] Table 4

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump spread | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| sand rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com