Self-compacting cement soil slurry for unbackfilled trench backfilling

A cement-soil and self-compacting technology, which is applied in filling, construction, etc., can solve the problems of uncompacted backfilling of fertilizer tanks, and achieve the effects of saving labor, shortening the construction period, and reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

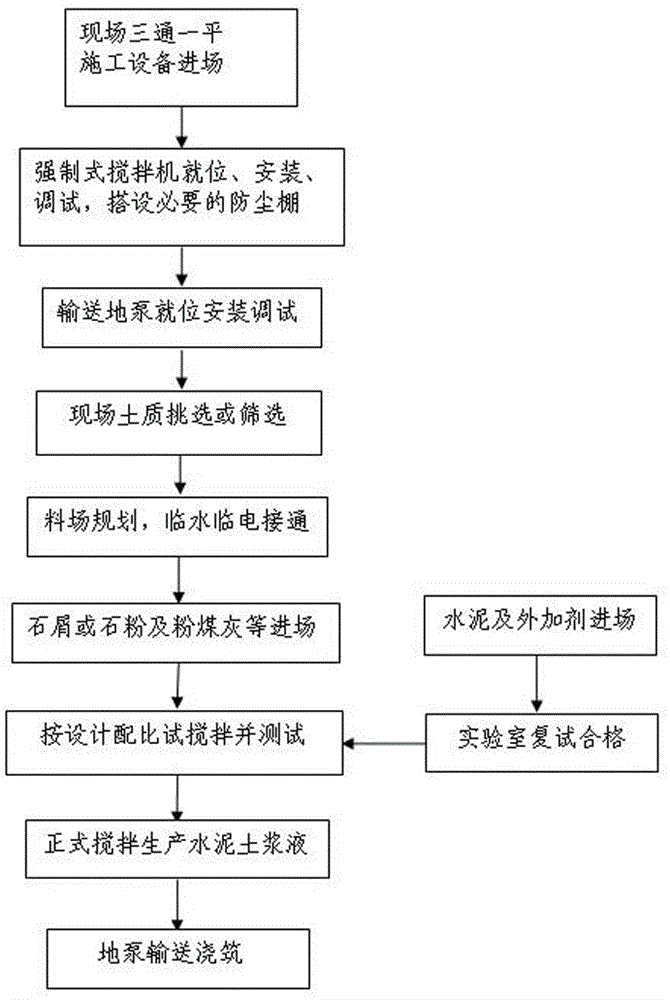

[0018] see figure 1 , adopt a kind of fertilizer groove backfill of the present invention to use the construction technique of compacting cement-soil slurry, main process comprises:

[0019] 1. Carry out conventional three links and one leveling on the construction site, and construction equipment enters the site.

[0020] 2. The forced mixer is in place, installed and debugged, and the necessary dust-proof shed is set up.

[0021] 3. The conveying ground pump is installed and debugged in place.

[0022] 4. On-site soil selection or screening.

[0023] 5. Stock yard planning, water and power connection.

[0024] 6. Stone chips or stone powder and fly ash enter the site; cement and admixtures enter the site, and these materials pass the laboratory retest.

[0025] 7. Stir and test according to the design ratio: the material formula used is that the materials used in each cubic meter are: cement 100~400kg, local soil 500~900kg, stone chips or stone powder 200~400kg, fly ash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com