Fast and high-efficiency integrated ground

A ground and efficient technology, applied in the field of manufacturing, can solve the problems of long lifting period, loud construction noise, difficult maintenance, etc., and achieve the effects of reducing construction dust, reducing construction noise and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

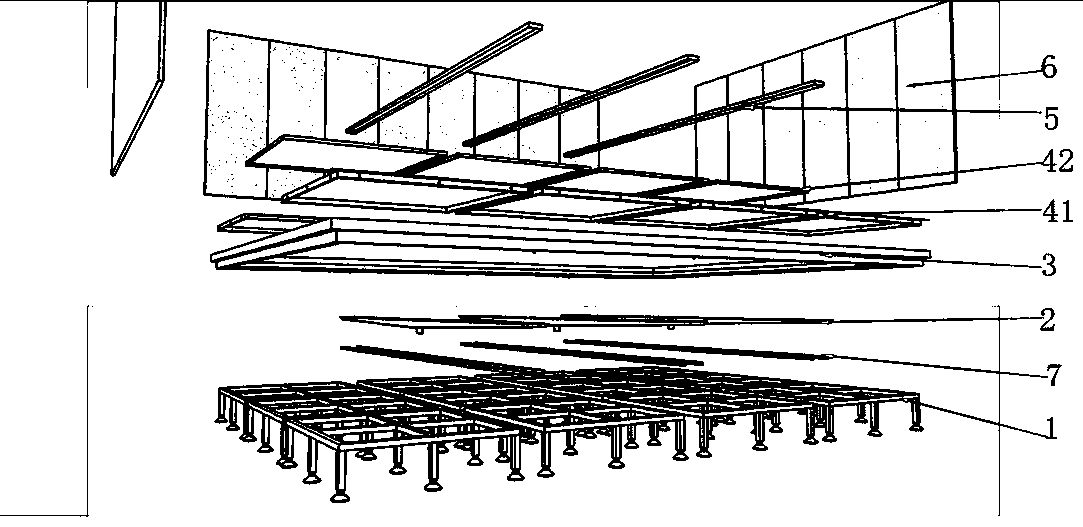

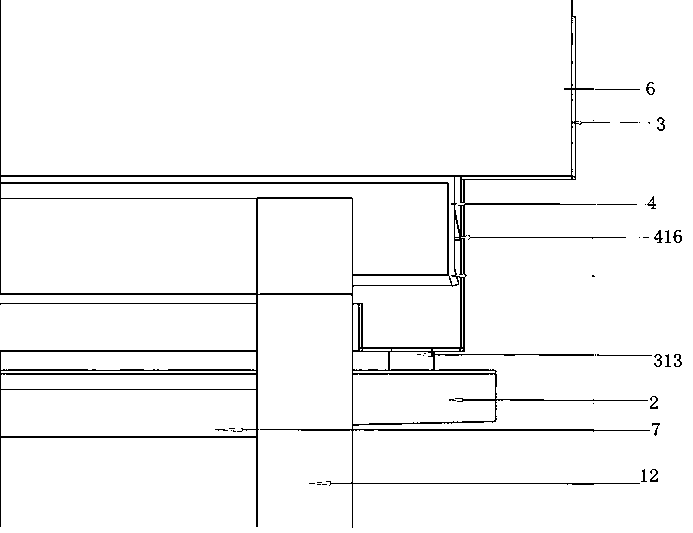

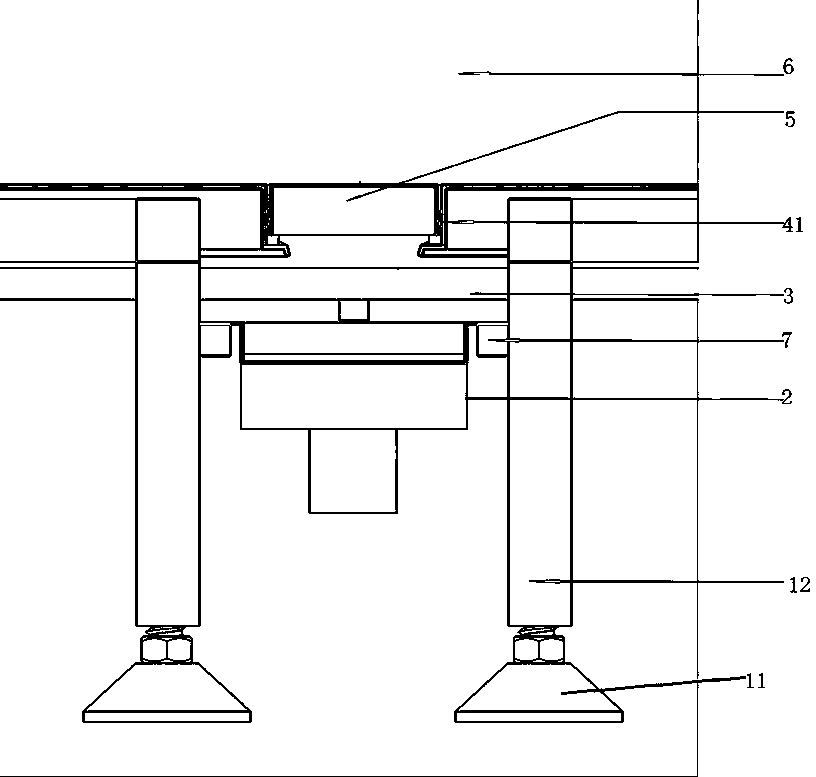

[0036] A fast and efficient integrated ground as shown in the figure includes: at least one set of ground base 1, drainage groove 2, special-shaped water guide groove 3 at the side of the wall, floor 4, sink cover plate 5 and wall panel 6, and the drainage groove 2 passes through The drainage tank fixing frame 7 is fixed between the two ground bases 1, the wall side special-shaped water guide channel 3 is installed above the ground base 1, and the water tank cover plate 5 is installed in the gap between the floors 4 above the drainage tank 2 The wall panel 6 is installed on the periphery of the base 1 on the ground, and placed in the frame of the special-shaped water guide trough 3 beside the wall.

[0037] In the present embodiment, the ground base 1 is provided with a group of heavy-duty adjustment feet 11, a group of uprights 12 and a support frame 13, the heavy-duty adjustment feet 11 are arranged at the bottom of the uprights 12, and the support frame 13 is arranged at the...

Embodiment 2

[0046]A fast and efficient integrated ground as shown in the figure includes: at least one set of ground base 1, drainage groove 2, special-shaped water guide groove 3 at the side of the wall, floor 4, sink cover plate 5 and wall panel 6, and the drainage groove 2 passes through The drainage tank fixing frame 7 is fixed between the two ground bases 1, the wall side special-shaped water guide channel 3 is installed above the ground base 1, and the water tank cover plate 5 is installed in the gap between the floors 4 above the drainage tank 2 The wall panel 6 is installed on the periphery of the base 1 on the ground, and placed in the frame of the special-shaped water guide trough 3 beside the wall.

[0047] In the present embodiment, the ground base 1 is provided with a group of heavy-duty adjustment feet 11, a group of uprights 12 and a support frame 13, the heavy-duty adjustment feet 11 are arranged at the bottom of the uprights 12, and the support frame 13 is arranged at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com