Wall connector of scaffold and its construction method of buckling member type steel pipe scaffold

A technology of connectors and scaffolding, which is applied to the accessories of scaffolding, buildings, building structures, etc., and can solve the problems of reducing the anti-penetration ability of building walls, high noise, and heavy workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

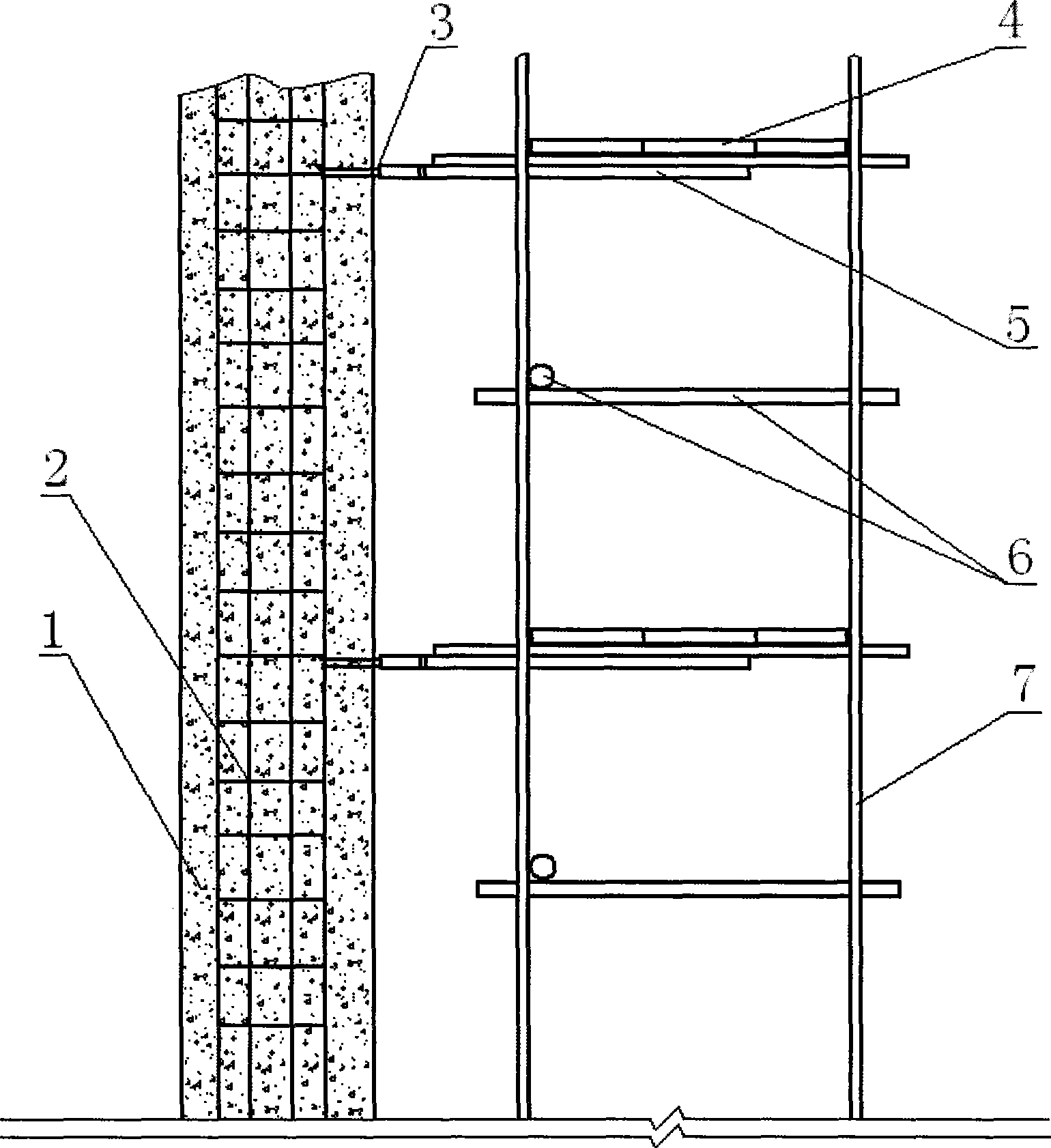

[0024] Such as figure 1 As shown, the fastener-type steel pipe scaffolding includes a scaffold board 4, a connecting rod 5, a wall connecting piece 3, and cross bars 6 and longitudinal bars 7 interlaced with each other. The wall connecting piece 3 is fixedly connected to the connecting rod 5, and the wall connecting piece 3 The concrete passing through the building wall 1 is connected to the building reinforcement body 2, and the function of the wall connector 3 is to fix the scaffold body, prevent lateral instability, and ensure the safety and reliability of the scaffold.

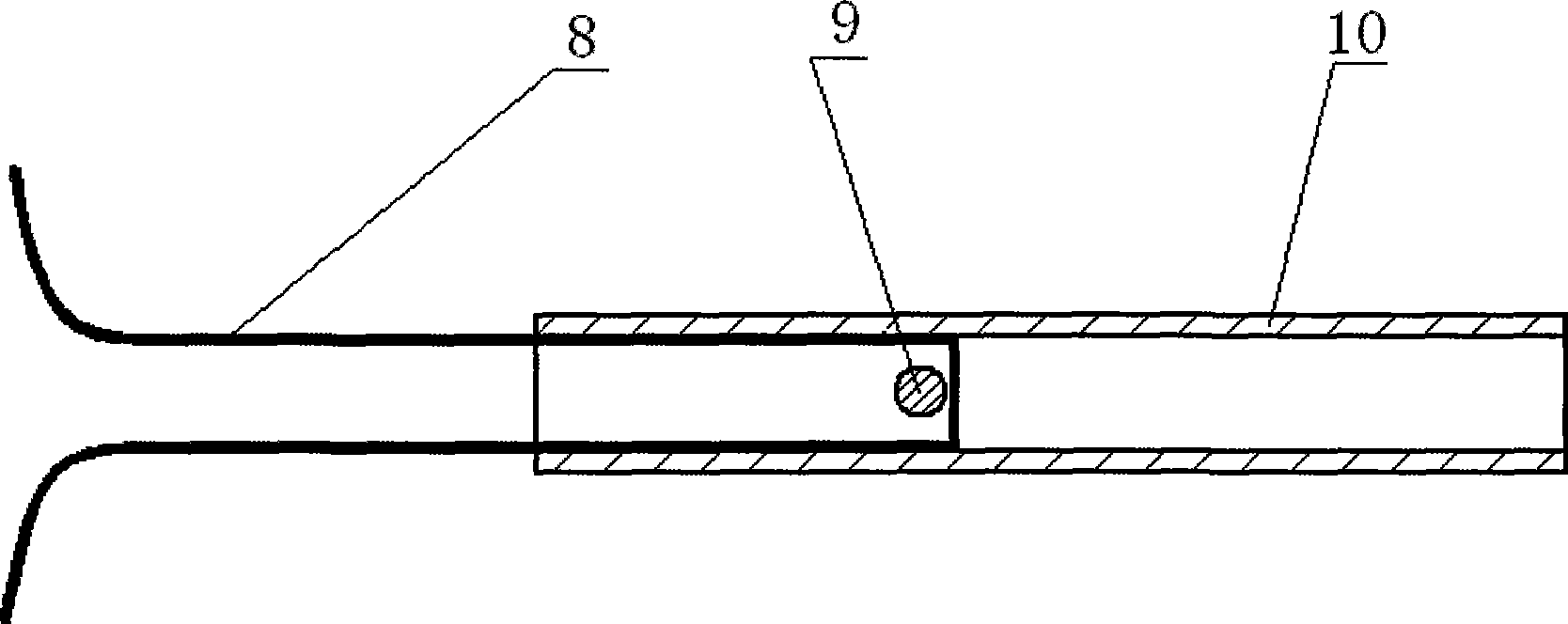

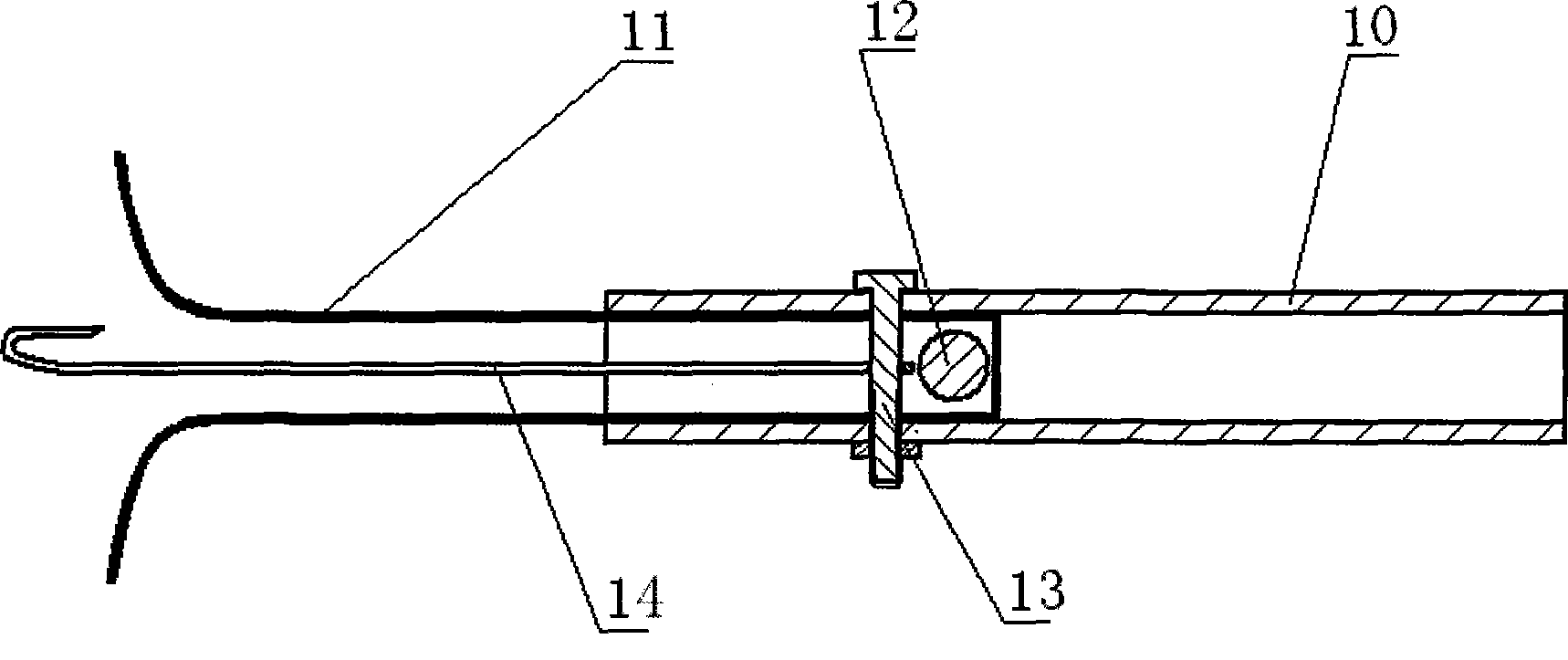

[0025] figure 2 Shown the first kind of preferred embodiment of the wall connector of scaffolding of the present invention, it is made up of connector reinforcing bar 8, connector steel pipe 10 and fixture 9, and the shape of connector reinforcing bar 8 is made the rectangle that one end is open, connects The steel bar 8 of the connecting piece extends into the steel pipe 10 of the connecting piece. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com