Prefabricated ultra-high-performance concrete pi-shaped beam unit, bridge structure and construction method thereof

An ultra-high performance, bridge structure technology, used in bridges, bridge parts, bridge materials, etc., can solve the problems of easy cracks in the beam body, increased difficulty in steel reinforcement, low tensile strength, etc., to reduce the number of joints and diaphragms. , Reduce the risk of cracking, the effect of simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

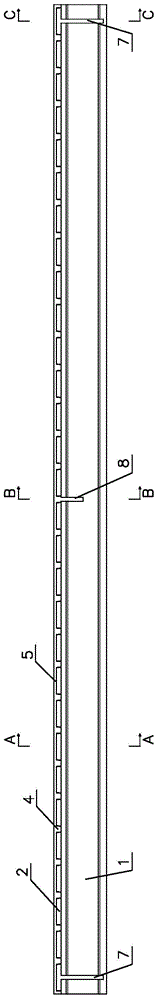

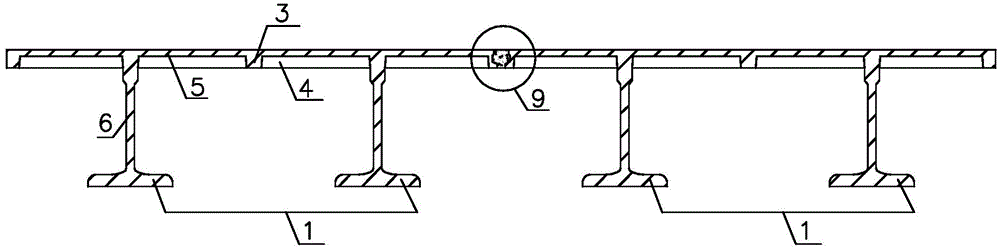

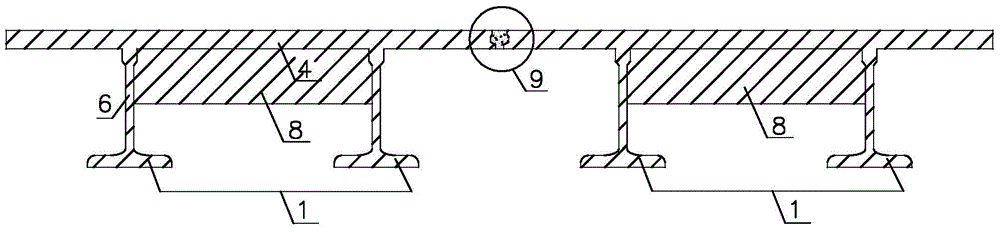

[0041] Such as Figure 1 to Figure 5 Shown, a kind of π-shaped bridge structure that prefabricated ultra-high performance concrete π-shaped beam unit of the present invention is formed, the π-shaped bridge structure of each single span is to be formed by connecting two π-shaped beam units, and this π-shaped beam unit is Splice across the bridge.

[0042] Such as Figure 2 ~ Figure 4 As shown, the π-shaped beam unit of this embodiment is integrally prefabricated by T-shaped double main girders 1 and bridge deck 2 supported by T-shaped double main girders 1; The two girder webs 6 and the bridge deck 2 are grid-like thin plates with longitudinal ribs 3 and transverse ribs 4 at the bottom. The bridge deck 2 is set as a connecting part along the longitudinal side of the bridge, and the connecting part extends A connecting bar 10 (connecting bar 10 in this embodiment includes a U-shaped bar) that is seam-connected with another adjacent π-shaped beam unit. When the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com