Integral hollow slab bridge structure based on ultra-high-performance concrete connection and construction method thereof

An ultra-high performance, bridge structure technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems that the disease has not been fundamentally solved, the horizontal integrity of the hollow slab is low, and the strength of ordinary concrete is low, and it can solve the problem of asphalt paving Easy to break, improve long-term use performance and durability, and improve the effect of lateral connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

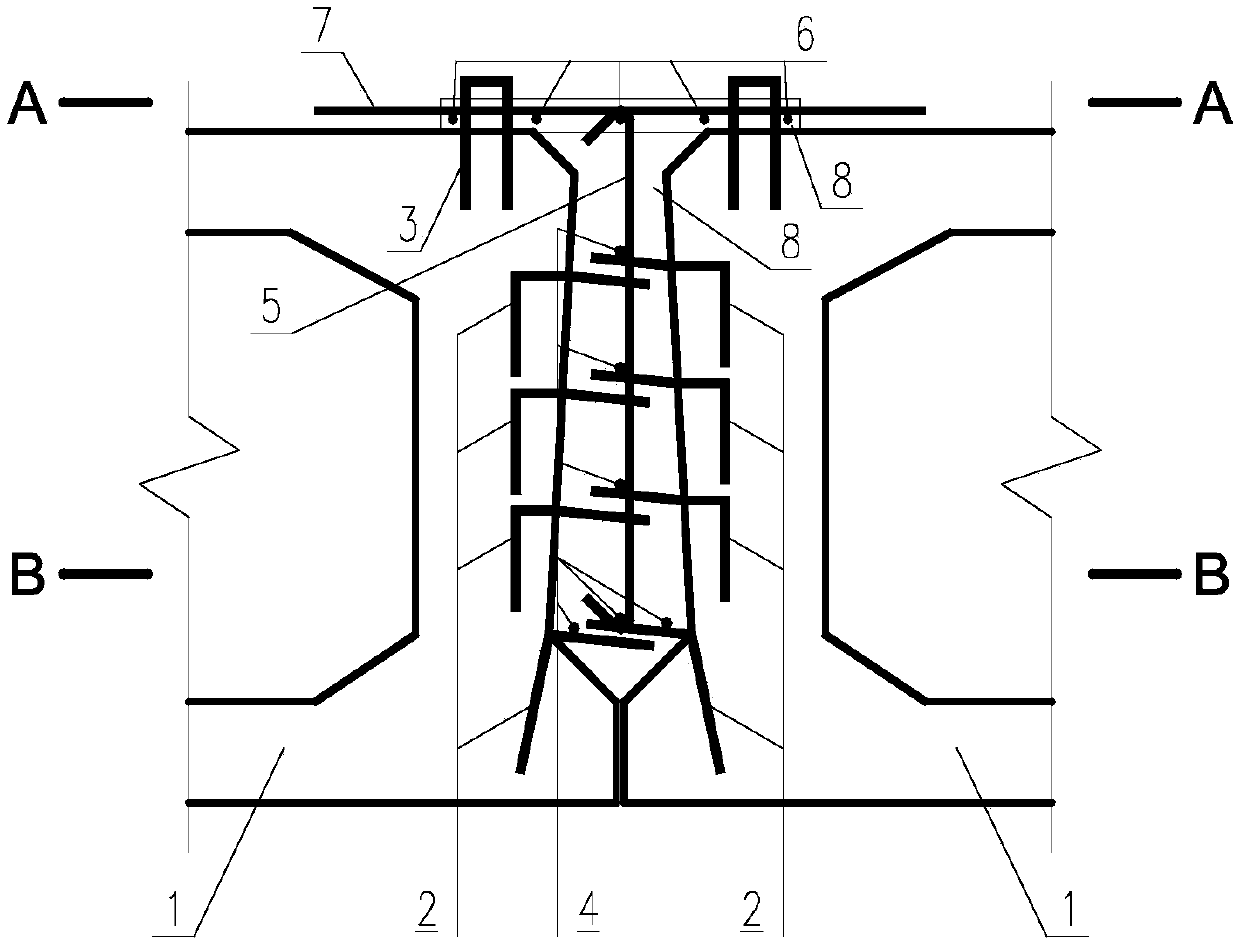

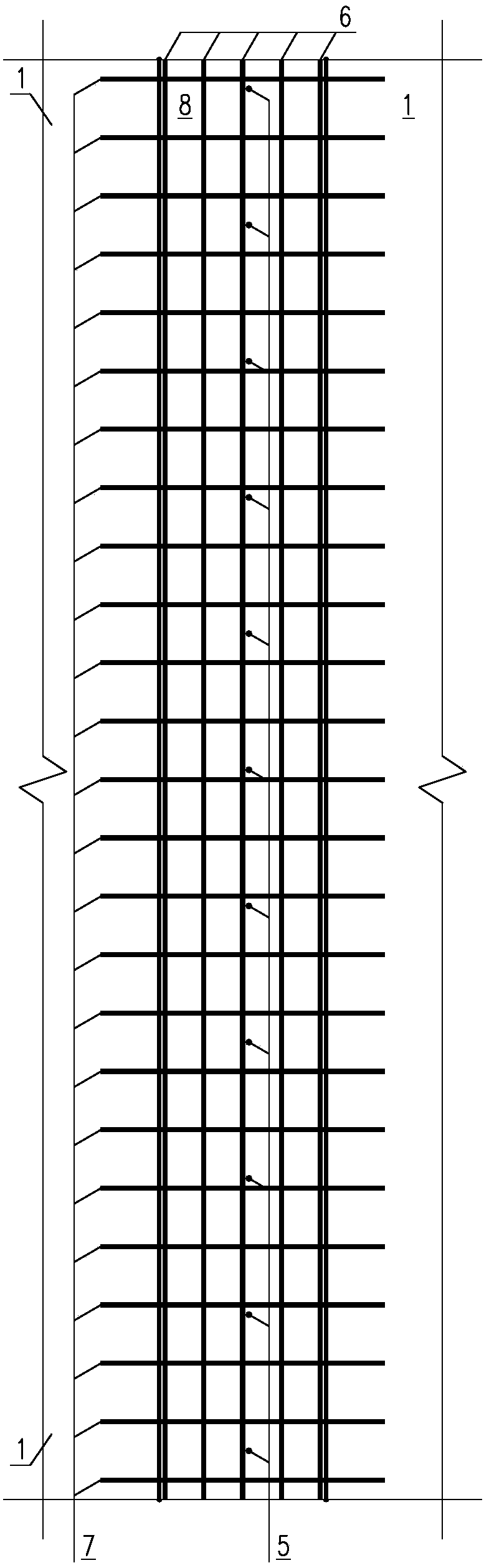

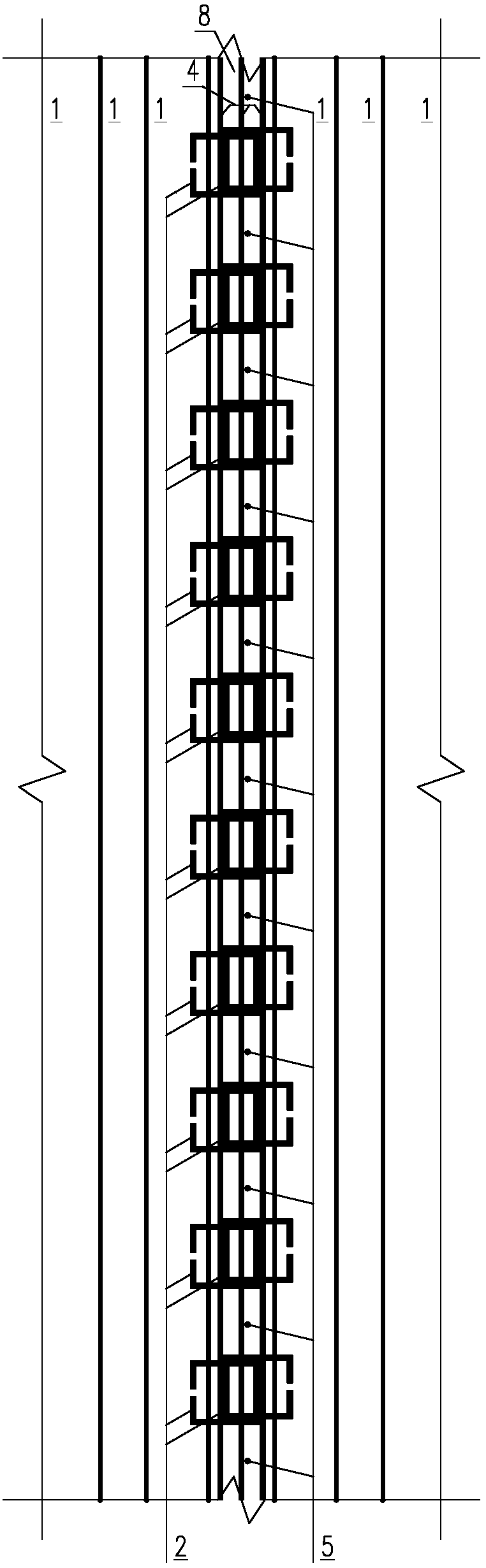

[0044] Such as Figure 1 to Figure 6 As shown, the integrated hollow slab bridge structure connected by ultra-high performance concrete in this embodiment is composed of three prefabricated hollow slab girders 1 passing through two ultra-high performance concrete joints and five superhigh Performance concrete transverse strips 13 are connected to form.

[0045] Such as Figure 1 ~ Figure 3 As shown, the ultra-high-performance concrete joint structure for the prefabricated hollow slab bridge of the present invention includes hinge joints 11 and ultra-high-performance concrete longitudinal strips 12 between two hollow slab girders. The hinged joint 11 is composed of two prefabricated hollow slab beams 1 webs and the pre-embedded transverse connecting steel bars 2 , longitudinal steel bars 4 , and stirrups 5 protruding from the webs to form a basic frame, which is filled with ultra-high performance concrete 8 . The ultra-high-performance concrete longitudinal strip 12 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com