Intermediate-frequency heating repaired opening construction technology for thermal contraction band of buried steel pipeline

A heat-shrinkable tape and construction technology technology, applied in the direction of pipe components, pipes/pipe joints/fittings, machinery and equipment, etc., can solve the problems of decreased adhesion of epoxy primers, insufficient melting of hot melt adhesives, slow heating up, etc. , to achieve the effect of improving the efficiency and quality of the repairing construction, ensuring the quality of the repairing anti-corrosion layer, and improving the overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1. In conjunction with accompanying drawing concrete implementation process description:

[0051] The pipe heat shrinkable joint construction technology with intermediate frequency heating is a dry film heat shrinkable joint construction process with intermediate frequency heating.

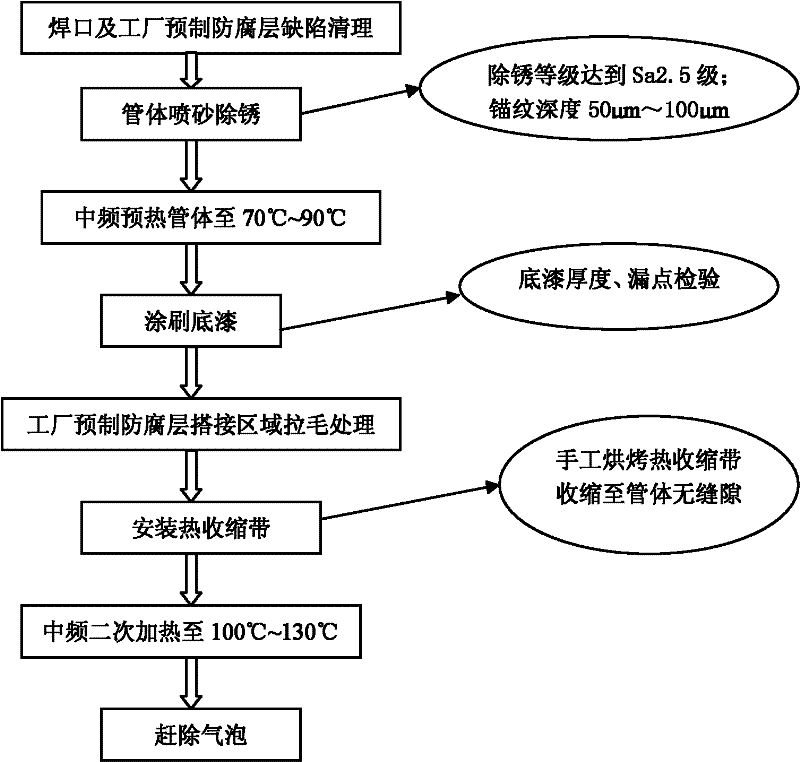

[0052] The construction process of dry film heat shrinkable joints with intermediate frequency heating (see figure 1 )for:

[0053] 1) Defect cleaning of welding joints and factory prefabricated anti-corrosion coatings: remove welding slag, dirt, and impurities at the repairing joints, and deal with defects existing in the overlapping areas of factory pre-fabricated anti-corrosion coatings;

[0054] 2) Sand blasting and rust removal of pipe body: rust removal grade Sa2.5; anchor pattern depth 80μm;

[0055] 3) Intermediate frequency preheating tube body: preheating temperature 60°C;

[0056] 4) Brushing primer: the thickness of the primer is more than 200μm;

[0057] 5) The s...

Embodiment 2

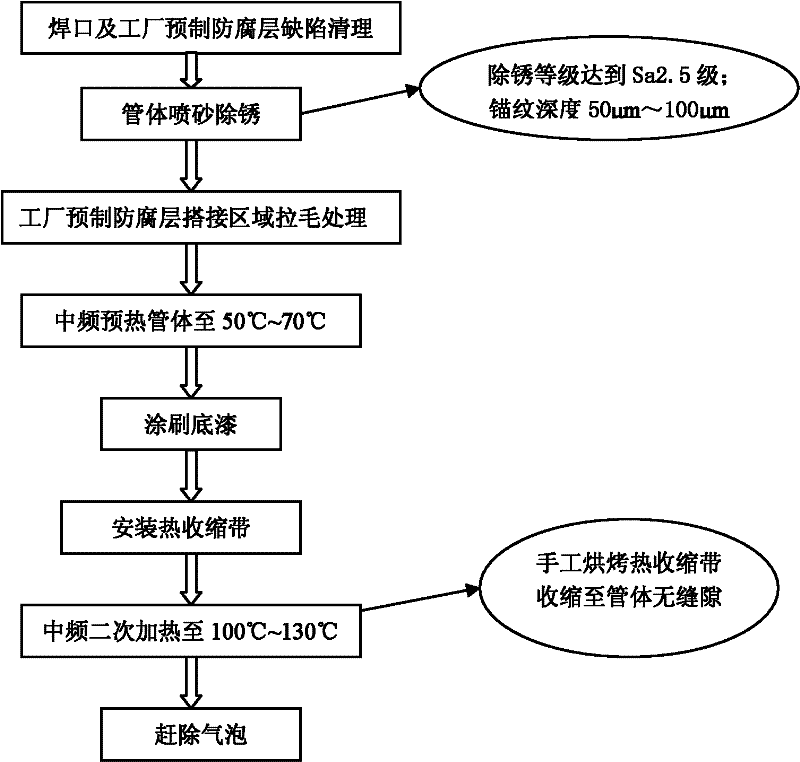

[0088] Embodiment 2. This example is the construction process flow of wet film heat shrinkable band intermediate frequency heating filling joint (see figure 2 ), it differs from the dry film heat shrinkable belt intermediate frequency heating joint construction process only in that: the surface roughening treatment of the factory prefabricated anti-corrosion layer is carried out in advance after the pipe body is blasted and derusted, which is the third step, other processes same.

[0089] in:

[0090] The specific methods of welding joints and factory prefabricated anti-corrosion layer defect cleaning, pipe body sandblasting and rust removal, intermediate frequency preheating pipe body, intermediate frequency secondary heating and air bubble removal are the same as in Example 1, except that

[0091] The scope of primer painting in the primer: when the wet film is installed, the metal of the joint pipe body and the overlapping area of the factory prefabricated anti-corrosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com