Ultra-deep soft soil pile integral construction method based on high-precision information monitoring

A construction method and high-precision technology, which can be used in foundation structure engineering, sheet pile wall, foundation structure test, etc., can solve the problems of load limitation of the upper and upper structures, limitation of construction technical conditions, inability to achieve high precision, etc. It is convenient for the position and verticality of the steel column, ensuring the construction efficiency and construction quality, and the effect of fast construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The steel structure welding process and the bolt connection construction process of this embodiment are all conventional technologies, and will not be repeated in this embodiment, and focus on the embodiment of the present invention related to the structure.

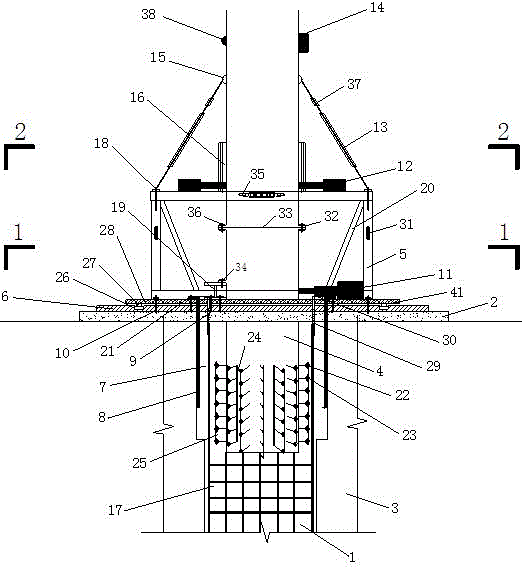

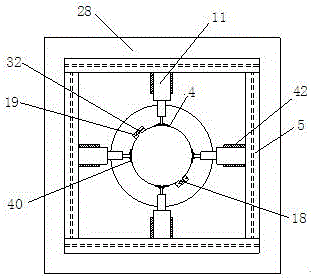

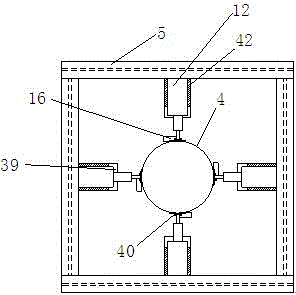

[0036] In the pile integrated information construction monitoring and positioning device of the present invention, the pile is a cast-in-situ pile 1, which is excavated from the original ground 2 to the soil layer 3, and the column is a steel column. The positioning device of the present invention includes a steel Column 4, steel column sleeve frame 5, steel casing 8 and casing bottom plate 28, said casing bottom plate 28 is fixed on the thin jack 27 on plain concrete cushion 6, steel casing 8 is positioned by steel casing screw rod 21 Fixed on the base plate 28 of the sleeve frame, the steel column sleeve frame 5 and the base plate 28 of the sleeve frame are fixed on the base plate 28 of the sleeve frame through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com