Trolley for tunnel full-face excavation, drilling and steel arch installation

A technology of steel arch frame and full section, which is applied in the direction of tunnel, tunnel lining, bolt installation, etc., to achieve the effect of convenient operation, stable control and guaranteed construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

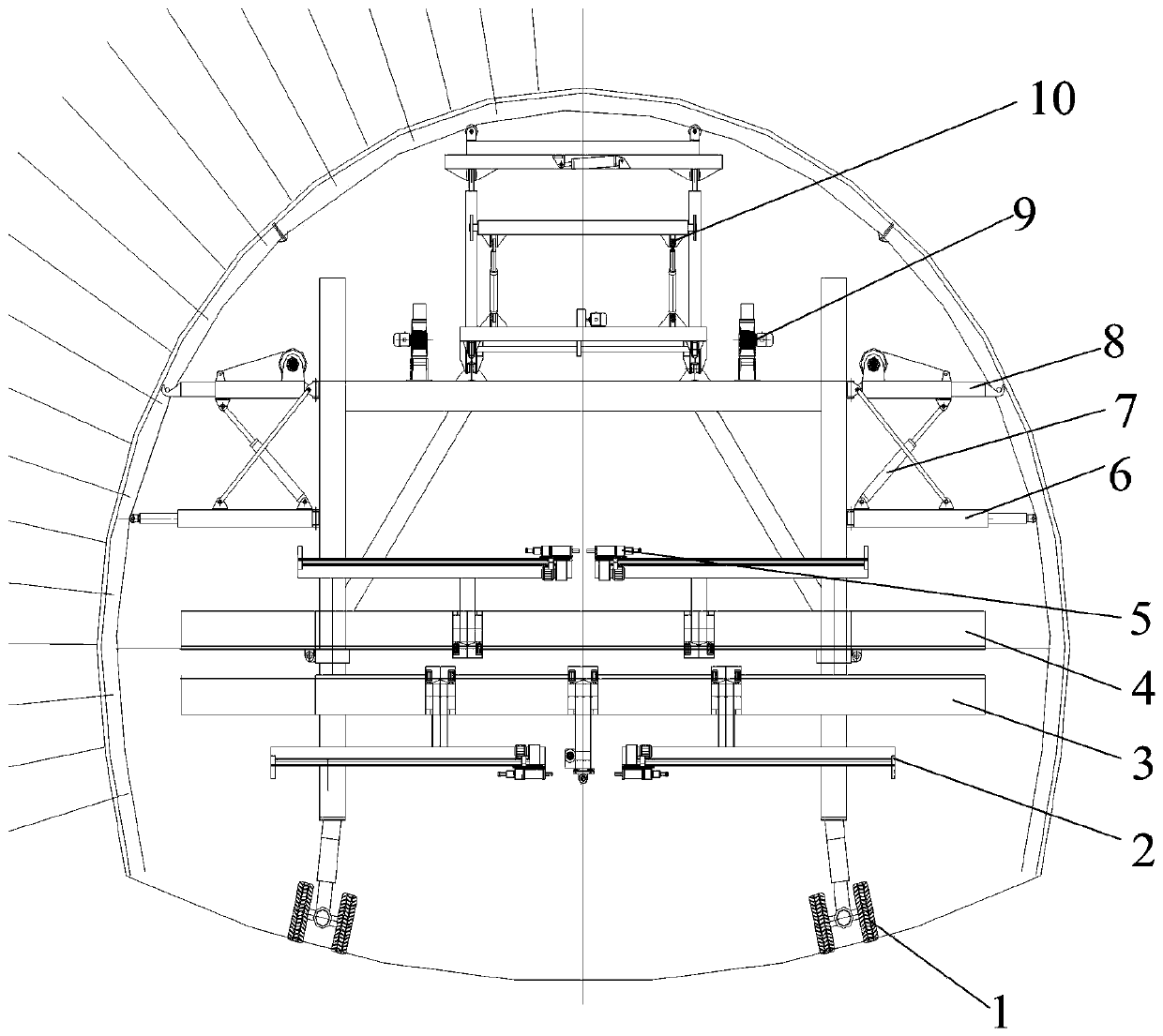

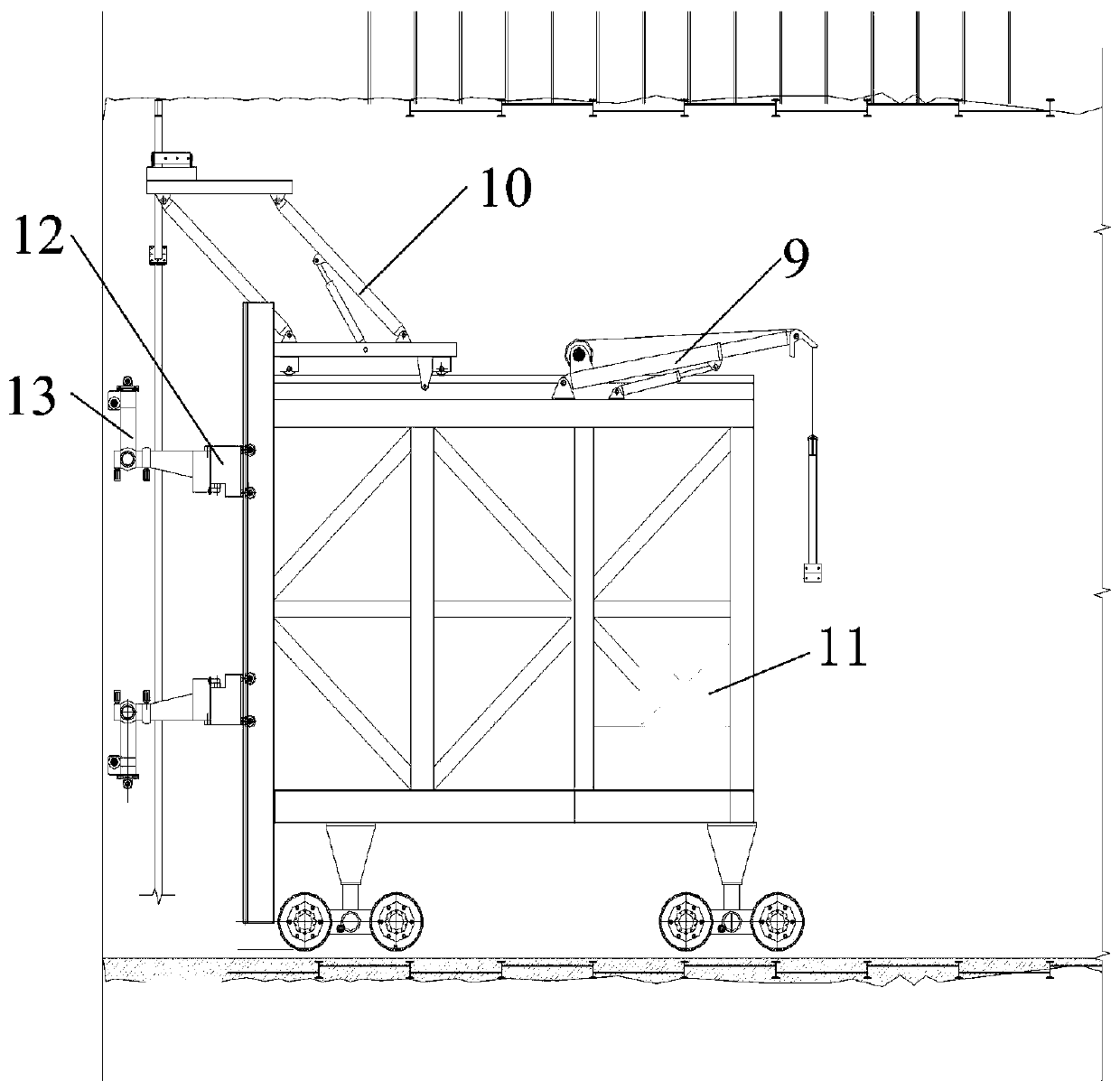

[0020] A trolley for full-section excavation of tunnels, rock drilling, and installation of steel arches, including mobile rollers 1, telescopic beams 2, bottom lifting support beams 3, top lifting support beams 4, rock drilling systems 5, and supporting hydraulic telescopic Arm 6, hydraulic rod 7, top hydraulic telescopic arm 8, telescopic boom 9, steel arch trolley 10 and hydraulic system 11.

[0021] The bottom lifting support beam 3 and the top lifting support beam 4 are arranged in parallel, and a hydraulic cylinder is arranged between the bottom lifting support beam 3 and the top lifting support beam 4, and the lifting support beam 3 at the bottom and the top lifting support beam 4 are adjusted by the hydraulic cylinder. distance. The telescopic crossbeam 2 is provided with two groups, and one group of telescopic crossbeam 2 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com