Spatial curved surface steel structure pipe truss roof installation construction method

A steel structure and pipe truss technology, which is applied to the installation and construction method of space curved steel structure pipe truss roofs, can solve the problems of difficult control of assembly and welding quality, large cumulative errors, and difficult construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

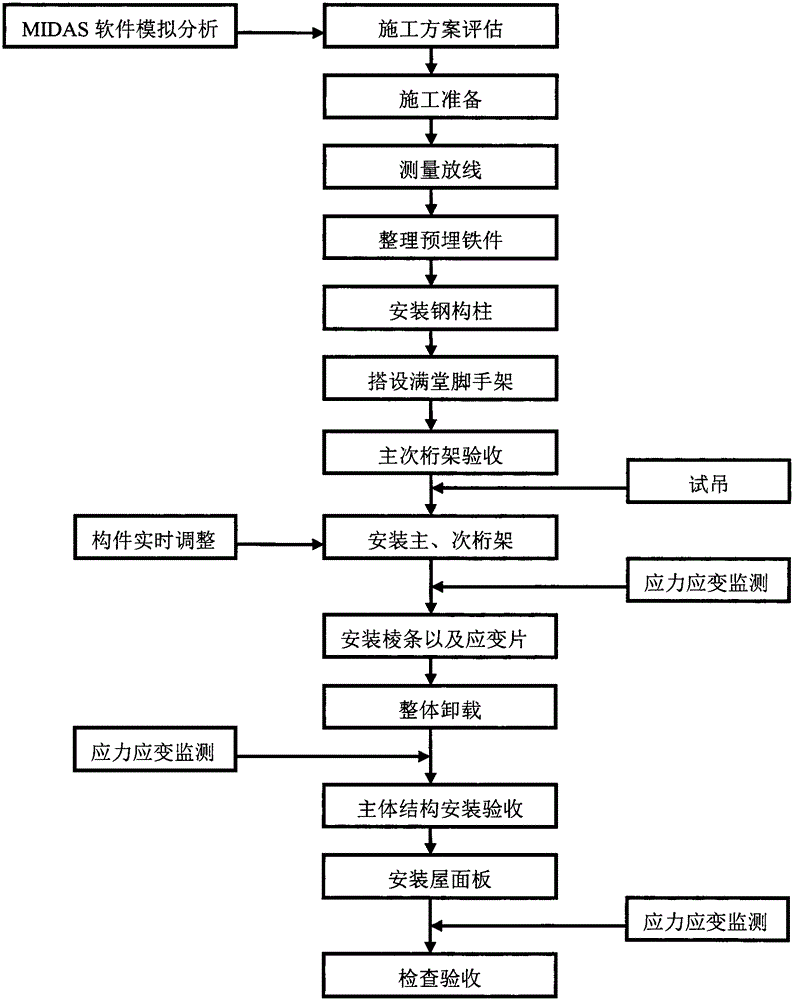

[0065] Such as figure 1 As shown, the space curved steel structure pipe truss roof installation construction method of the present invention comprises the following steps:

[0066] The first step: construction plan evaluation:

[0067] Before the official construction, the MIDAS software was used to simulate the construction plan in the non-linear construction stage. The stress and strain of each component during the construction process were investigated through the simulation, so as to evaluate the safety of the construction plan. The construction phase can only be entered after the simulation evaluation confirms that the construction plan is safe. During the construction stage, the stress and strain monitoring of the main components should be carried out according to the simulation analysis results.

[0068] The second step: construction preparation:

[0069] To level the road and installation site, the road for the crane to travel must be flat and solid, and steel subgr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com