Deformation control cantilever mounting method for large-diameter upright annular structure

A technology of cantilever installation and structural deformation, which is applied in the direction of building construction, construction, and building material processing, to achieve the effects of increasing stability, overcoming the high cost of construction measures, and ensuring roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

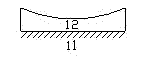

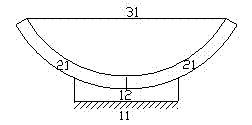

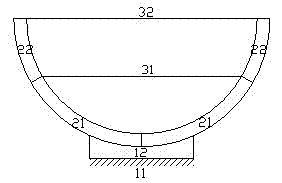

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail: the present invention is according to the roundness requirement that the upright annular structure designs, half ring is provided with horizontal stay cable to control the construction process of lower half ring in the opening installation state of ring structure and ensure that the installation process of the upper half ring does not cause the deformation of the lower half ring to deviate from the design position and outward; when the ring structure is installed and constructed to the upper half ring, install the mast and the stay cable to adjust The deformation of the upper half ring during the installation process ensures the roundness requirements after the structure is formed; before the ring is closed, the deformation and force of the entire ring are adjusted by the cantilever ends on both sides of the opening and closing opening through the jack, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com