Space truss structure aerial pairing integral slide installation method

A network frame structure and overall sliding technology, which is applied in the direction of building construction, construction, and building material processing, can solve problems such as high risk, long crane time, and high risk, and achieves easy and simple pairing operations, reducing High-altitude operation, the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

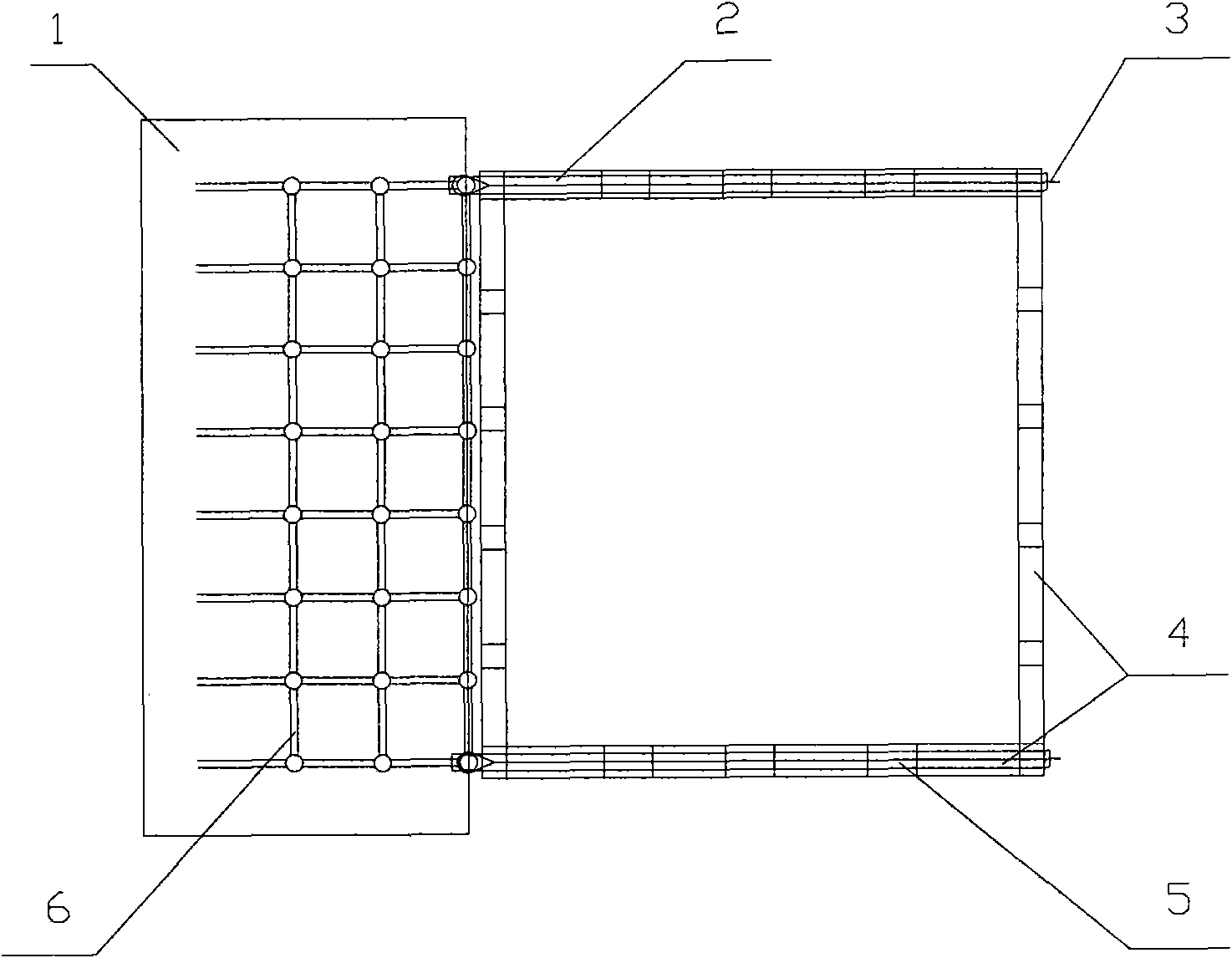

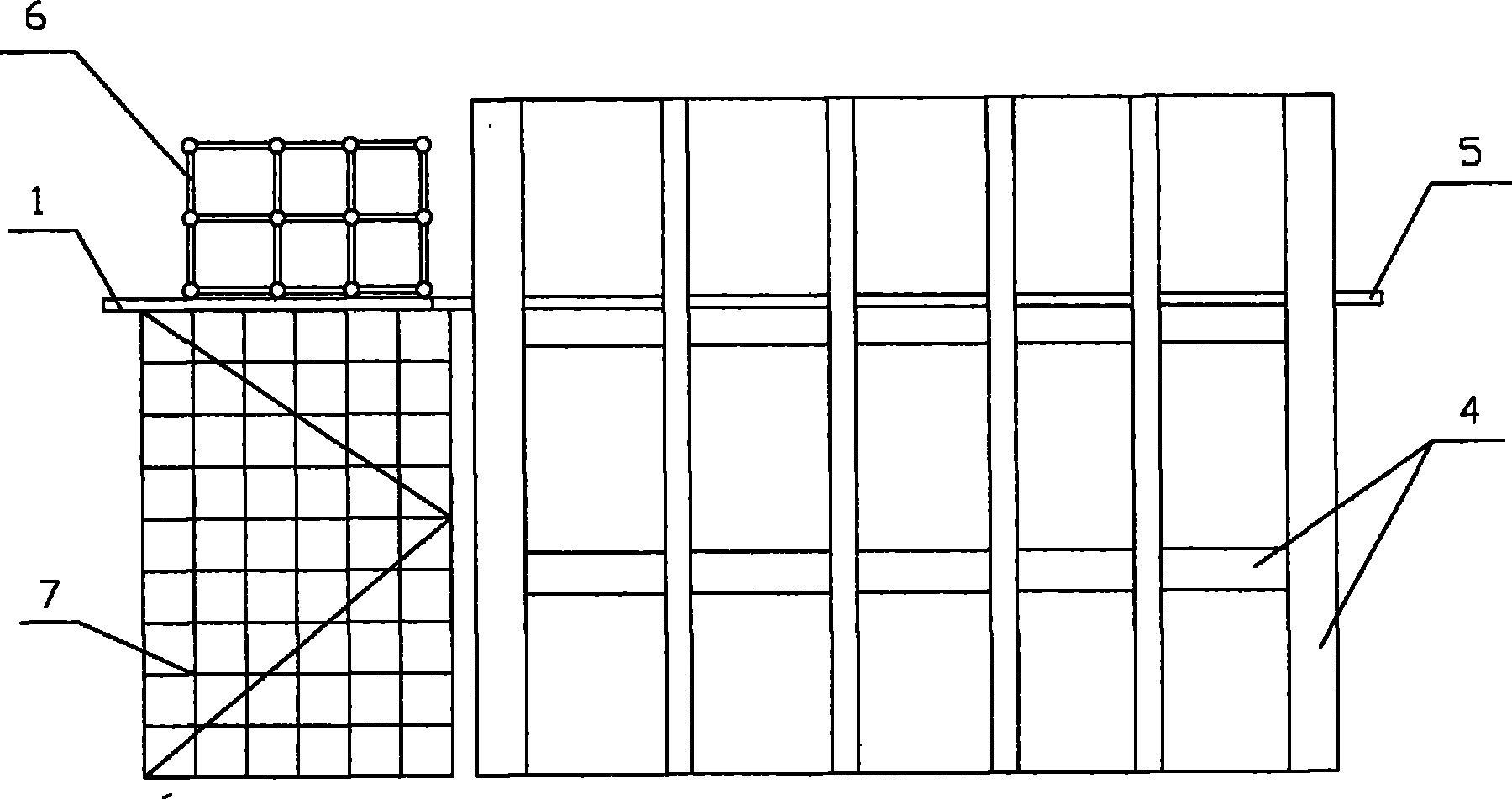

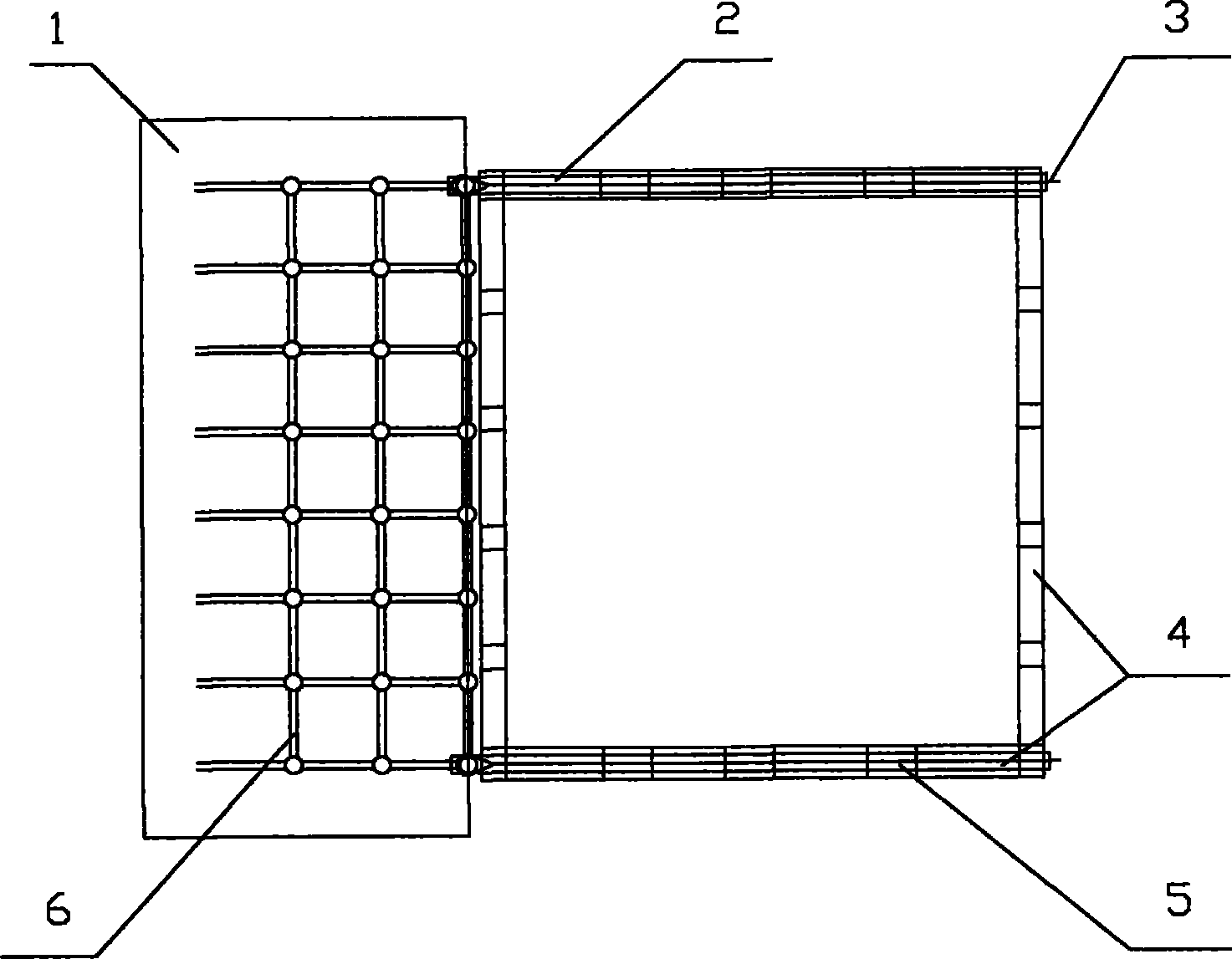

[0027] 1. High-altitude assembly platform

[0028] (1) Location selection of high-altitude assembly platform: The location selection of high-altitude assembly platform is the key to determine the sliding direction and sliding weight. The location of the high-altitude assembly platform should be selected according to many factors such as site conditions, supporting structure characteristics, and lifting machinery performance. The high-altitude platform is generally set up at the end of the grid (the sliding direction is from one end to the other); it can also be set up in the middle of the grid (if it is allowed to be erected in the middle of the site), and the sliding direction is from the middle to both ends; in order to reduce As far as the amount of shelves is concerned, the assembled platform should be built on the built structure as much as possible, and it is the most economical and ideal choice to use all or part of the built structure as a high-altitude platform.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com