Lower edge open truss style corrugated steel web combination beam

A technology of corrugated steel web and composite beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

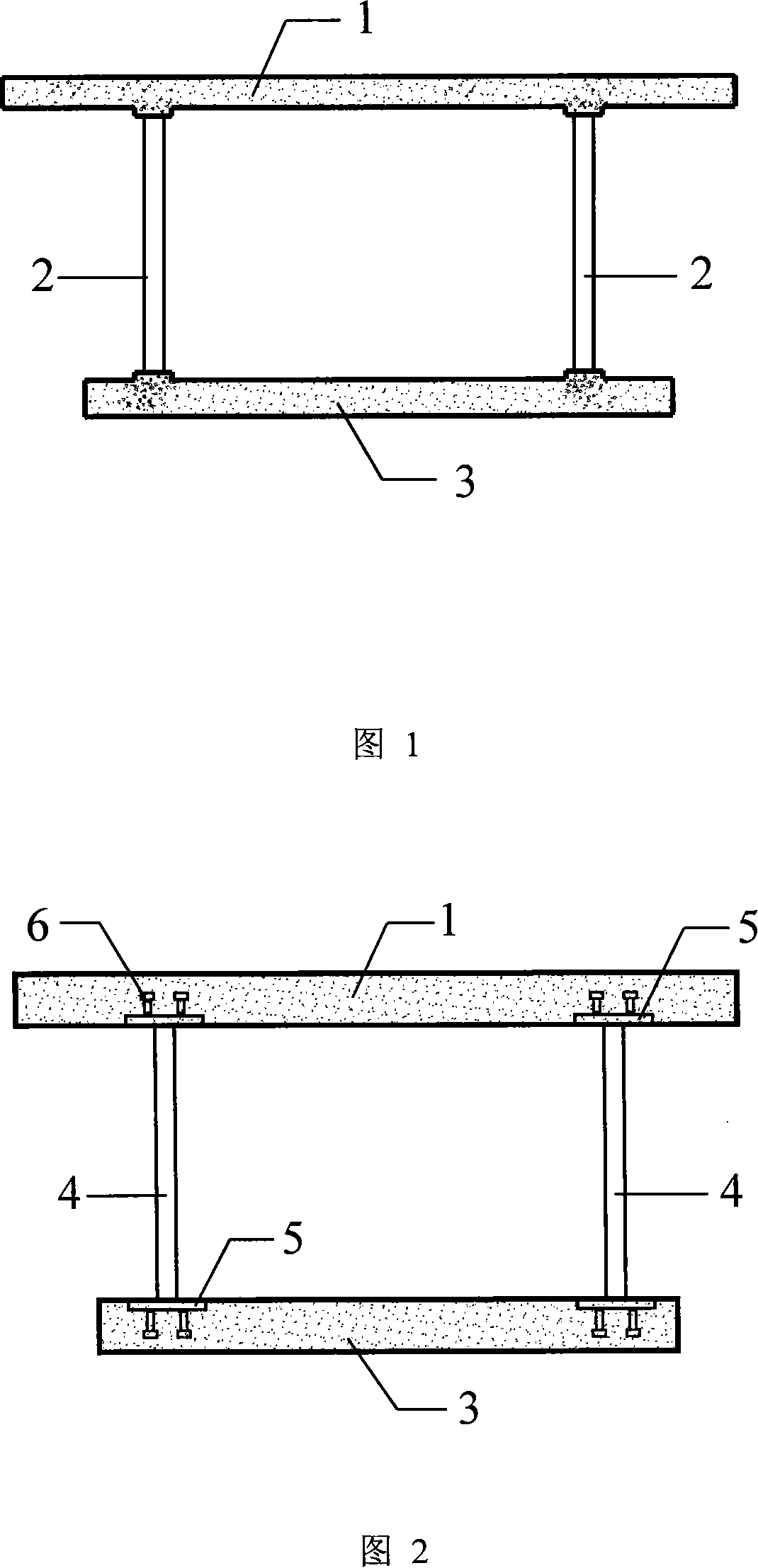

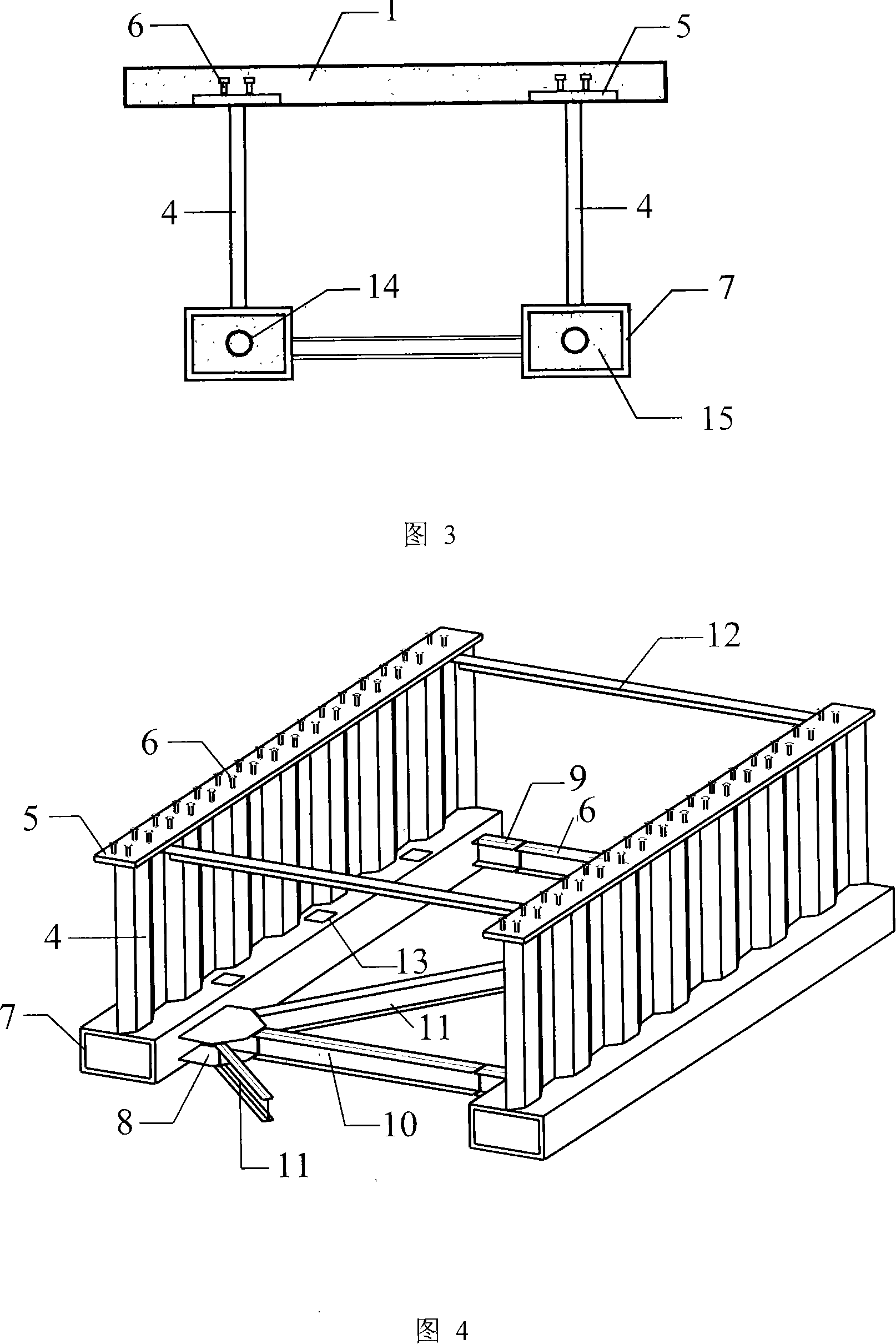

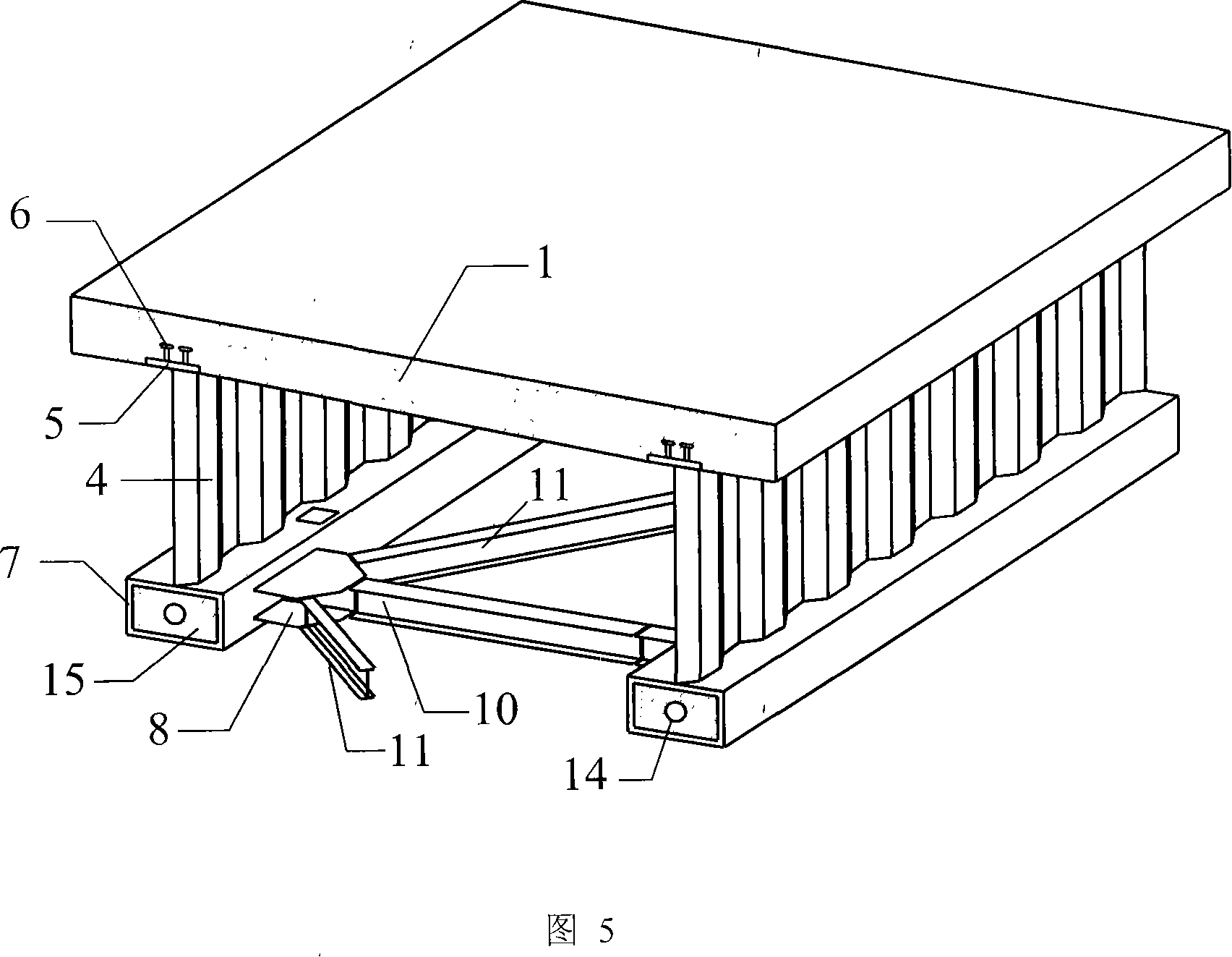

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] The invention provides a lower chord open truss type corrugated steel web composite beam that can greatly reduce the construction workload of the composite box girder for pouring concrete, erecting scaffolding, supporting formwork, etc., and can improve the structural bearing capacity, stiffness and crack resistance . As shown in Figures 3 to 5, the composite beam is composed of an upper flange concrete slab 1, a corrugated steel web 4, and a lower chord rectangular concrete-filled steel tube member. The lower chord rectangular steel tube concrete member adopts an open truss structure. The structure is composed of two rectangular steel pipes 7 arranged in parallel and the concrete 15 poured inside them, as well as the horizontal support 10 and the diagonal brace 11 arranged between the two rectangular steel pipes 7; The corbel A8 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com