Nuclear flexible manifold embedding electric smelting magnesium furnace fault monitoring method

A fault monitoring and fused magnesia furnace technology, applied in furnaces, charge materials, crucible furnaces, etc., can solve the problems of insufficient use of process monitoring, affecting the effect of monitoring, and difficulty for workers to achieve, so as to achieve improved monitoring effects and effective failures. Diagnose and realize the effect of monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

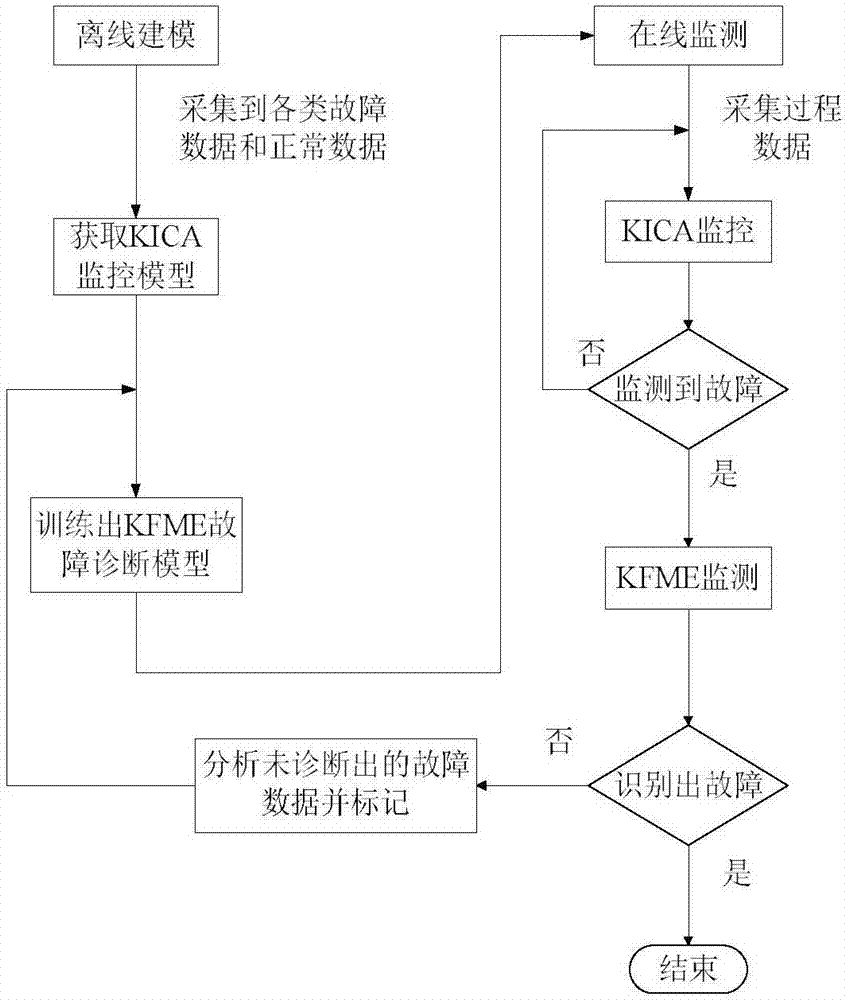

[0049] Such as figure 1 As shown, a nuclear flexible manifold embedded fused magnesium furnace failure monitoring method of the present invention comprises the following steps:

[0050] Collect various fault data and normal data;

[0051] Carry out offline modeling, obtain the KICA monitoring model according to the collected data, and train the KFME fault diagnosis model;

[0052] Online monitoring, using the KICA monitoring model for real-time online monitoring and collecting process data;

[0053] If a fault is detected, fault identification is performed through the KICA monitoring model;

[0054] If a fault is detected, a fault monitoring process ends.

[0055] If no fault is identified, analyze and mark the undiagnosed fault data, and go to the step of training the KFME fault diagnosis model.

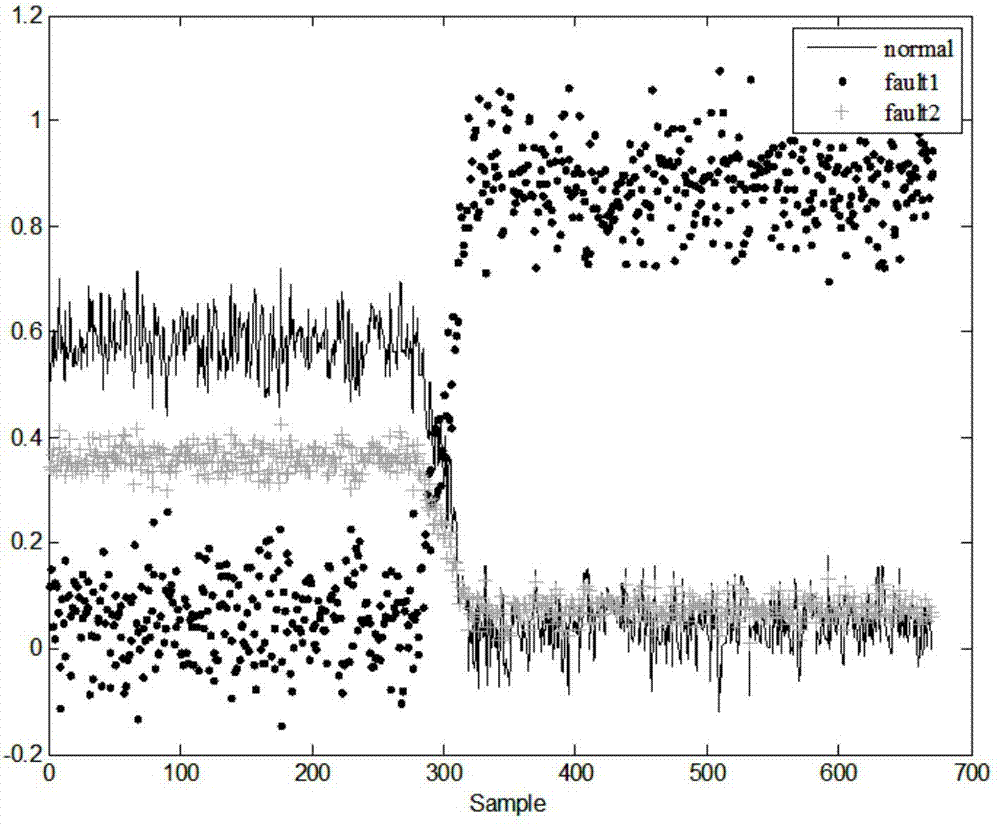

[0056] Among them, the KICA monitoring model i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com