Discrete manufacturing process product quality information management system based on RFID (radio frequency identification)

An information management system and product quality technology, applied in the field of discrete manufacturing process quality information management systems, can solve problems such as large workload, poor real-time performance, and low information utilization, improve automation, improve monitoring capabilities, and ensure unique sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

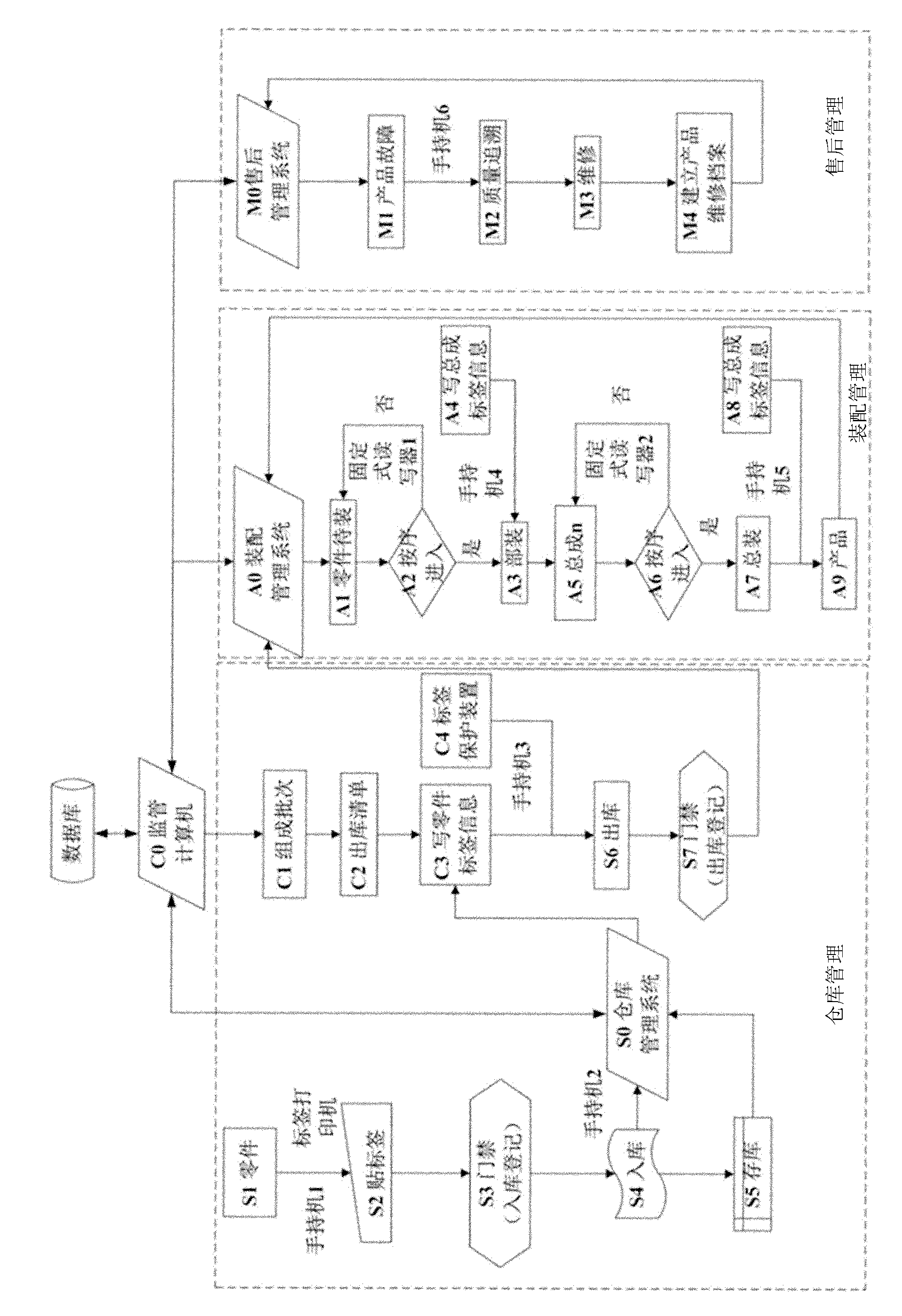

[0033] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

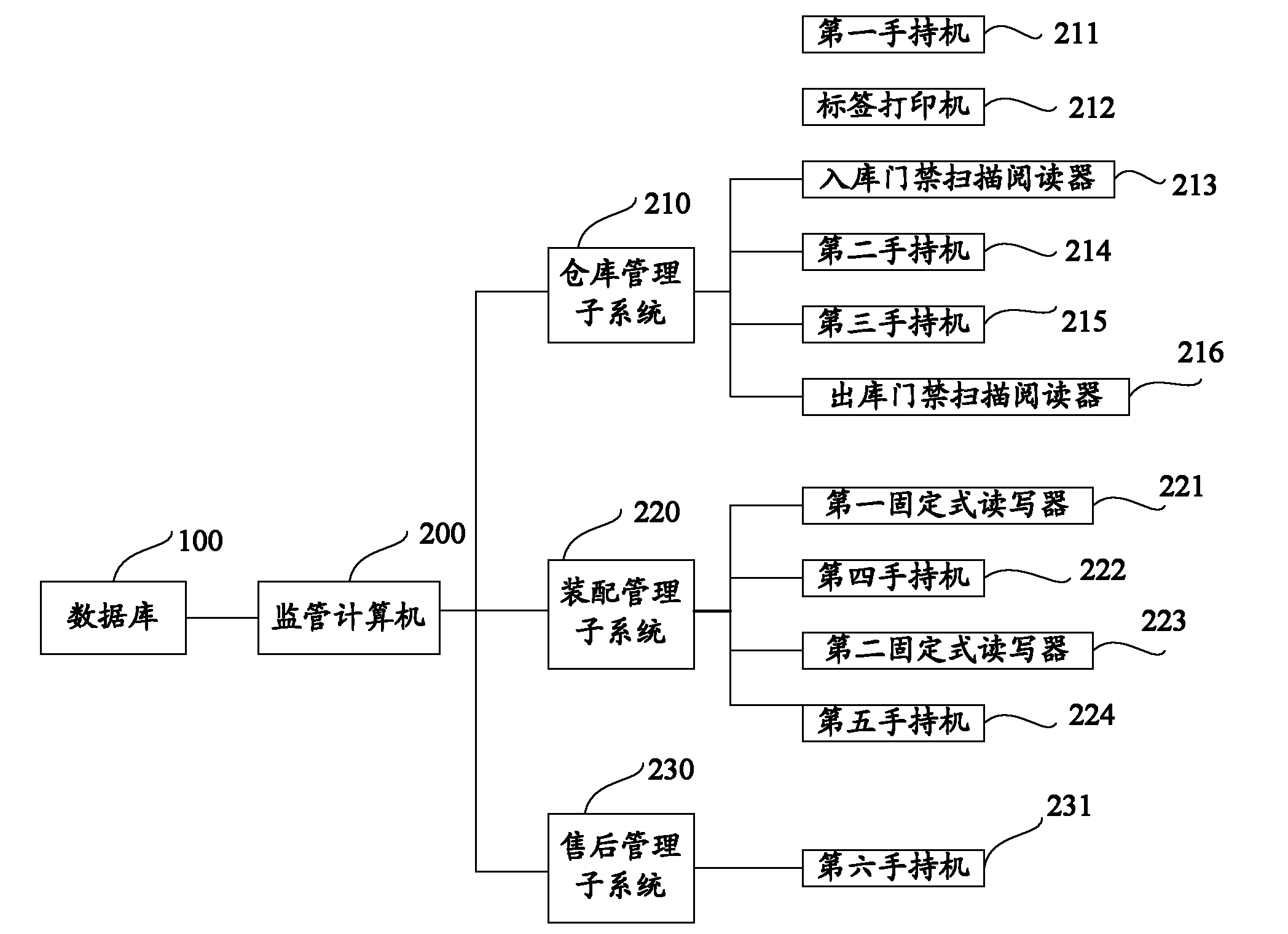

[0034] refer to figure 1 , the RFID-based discrete manufacturing process product quality information management system of the present invention includes a first handheld device (handheld scanning reader) 211, a label printer 212, a storage access control scanning reader 213, a second handheld device 214, a third handheld machine 215, outbound access control scanning reader 216, warehouse management subsystem 210, first fixed reader-writer 221, fourth handheld reader 222, second fixed reader-writer 223, fifth handheld reader 224, assembly management subsystem System 220 , sixth handset 231 , after-sales management subsystem 230 , supervisory computer 200 and database 100 .

[0035] The positions and respective functions of the above-mentioned components are described below.

[0036] The first handheld device 211 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com