Pipe flowing medium axial-flow-type pressure driver

A flow medium, axial flow technology, applied in the direction of engine components, machines/engines, sustainable buildings, etc., can solve the problems of not being able to use, not having much torque, and not being able to produce positive effects, etc., to achieve a simple and compact structure, which is beneficial to The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

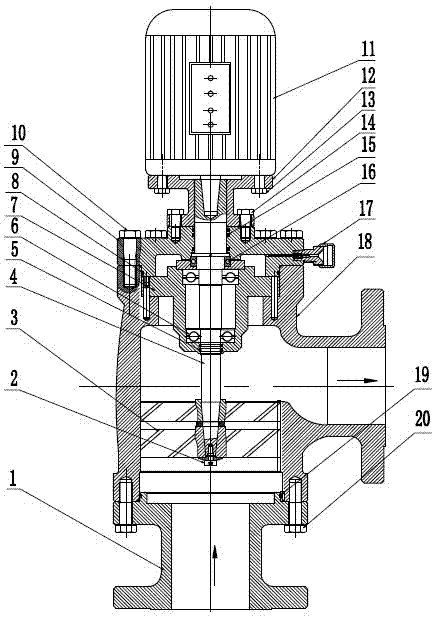

[0015] See figure 2 , including a three-way main valve body 18, the pipeline cavity at the outlet end of the main valve body 18 is bent upwards from the horizontal to the upper port, and the straight-through pipeline cavity from the upper port to the lower port is provided with a turbine 3 to drive One end of the shaft 4 is equipped with a turbine 3, the screw 2 passes through the inner taper hole of the turbine 3 and is connected with the outer cone of the drive shaft 4, and the end surface is fixed by internal thread engagement and compression.

[0016] In addition, the upper port of the main valve body 18 is equipped with a bearing seat 7 and an upper valve cover 9 in turn, and the bearing seat 7 is provided with a bearing A6, and the bearing A6 is sleeved behind the drive shaft 4, and the drive shaft 4 is equipped with a bearing B16 and then worn. Go out upper bonnet 9 central holes.

[0017] Further, the bolt A10 passes through the connection hole of the upper valve cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com