Patents

Literature

35results about How to "Facilitates automated implementation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

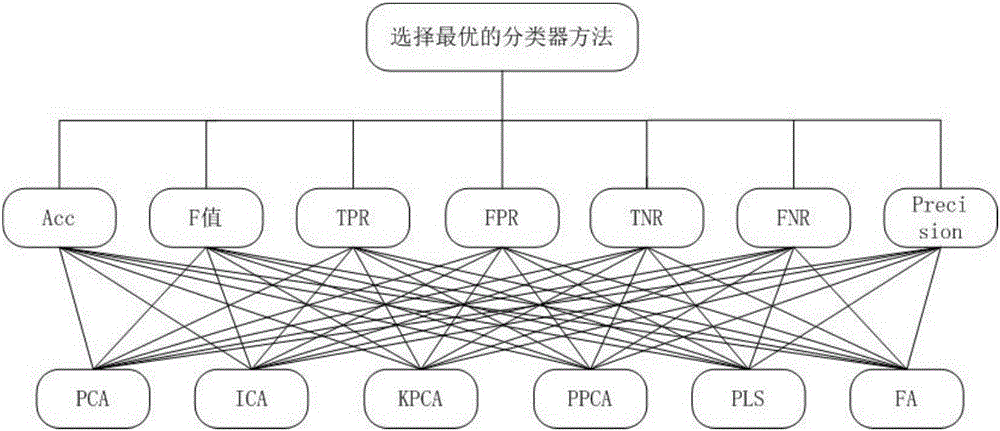

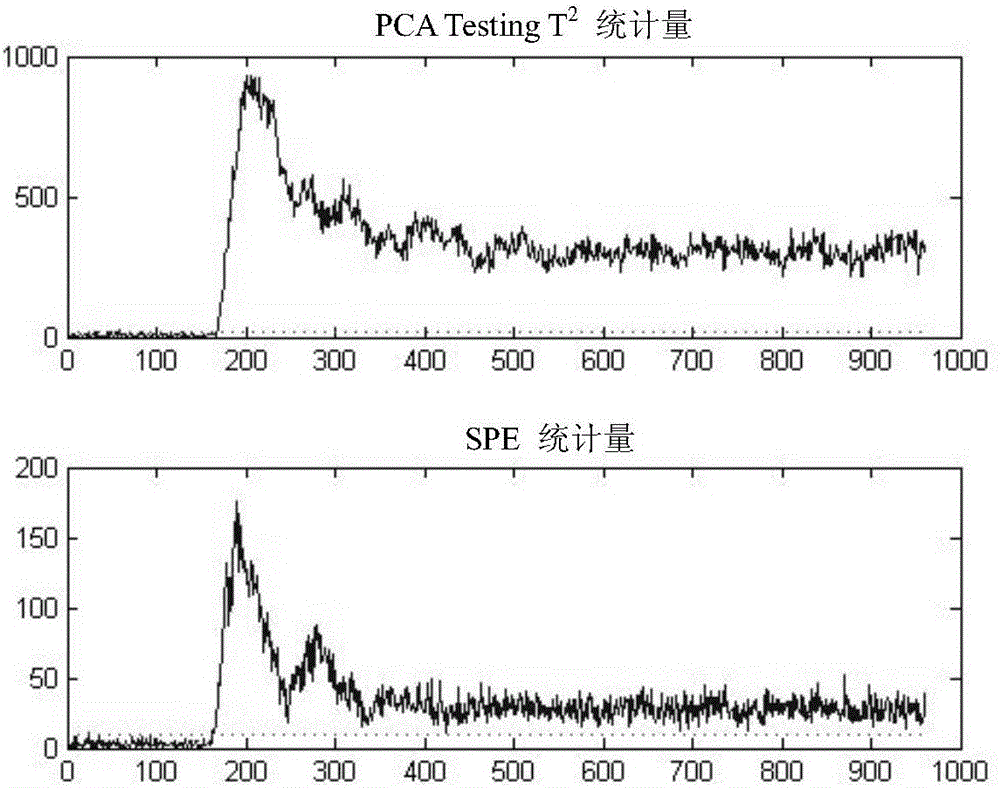

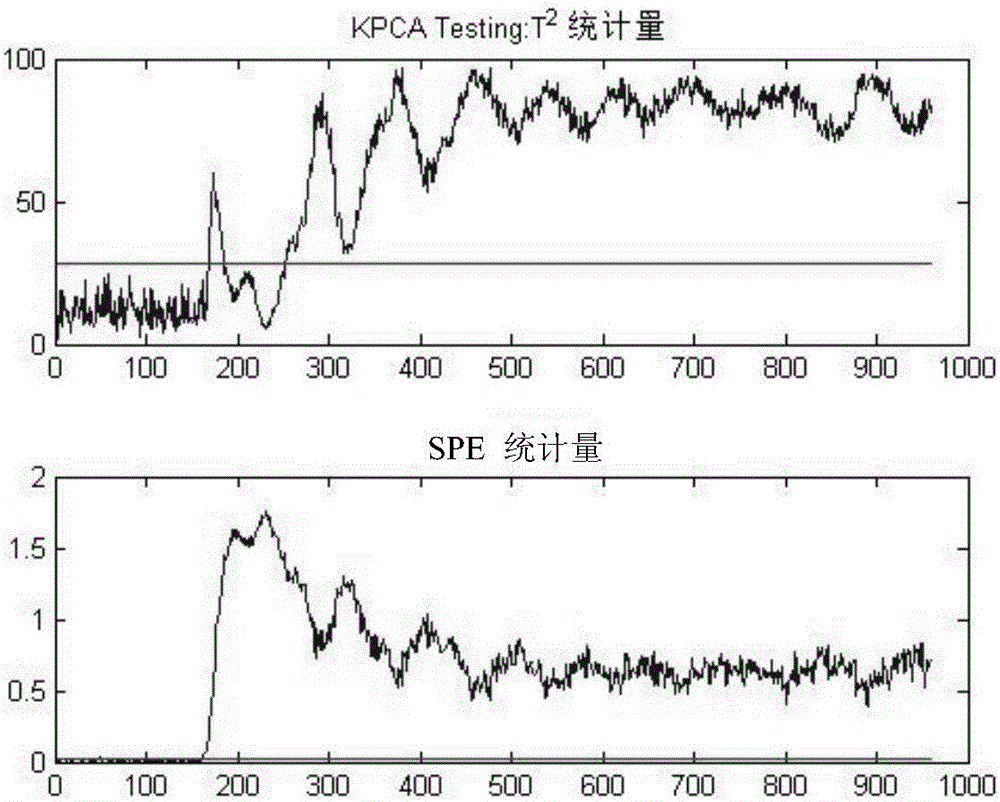

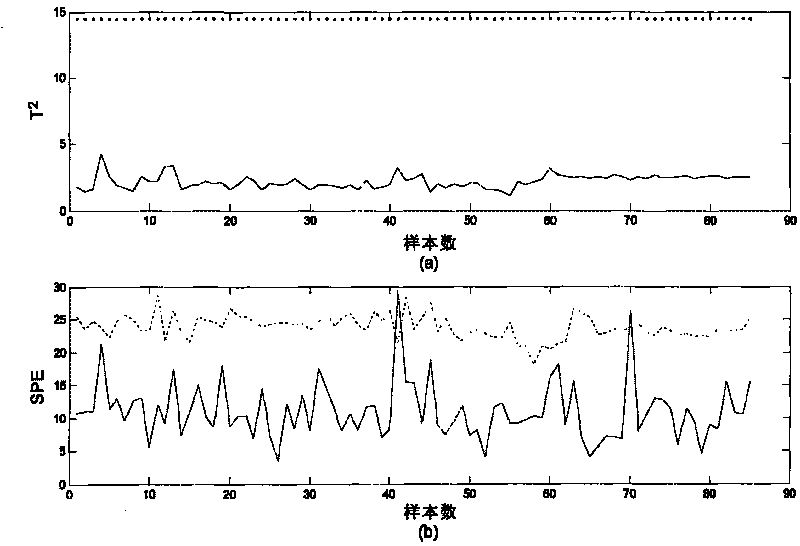

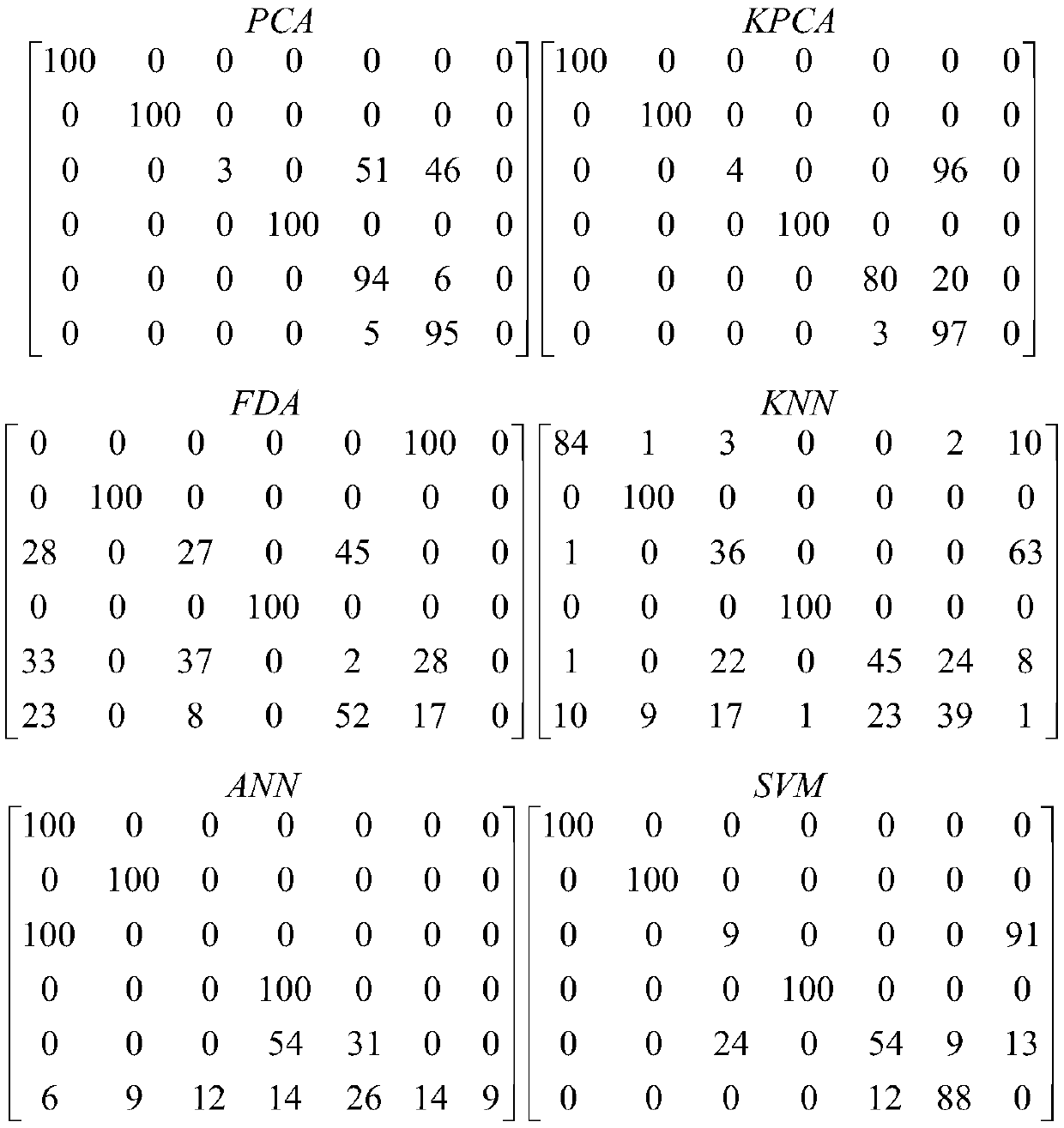

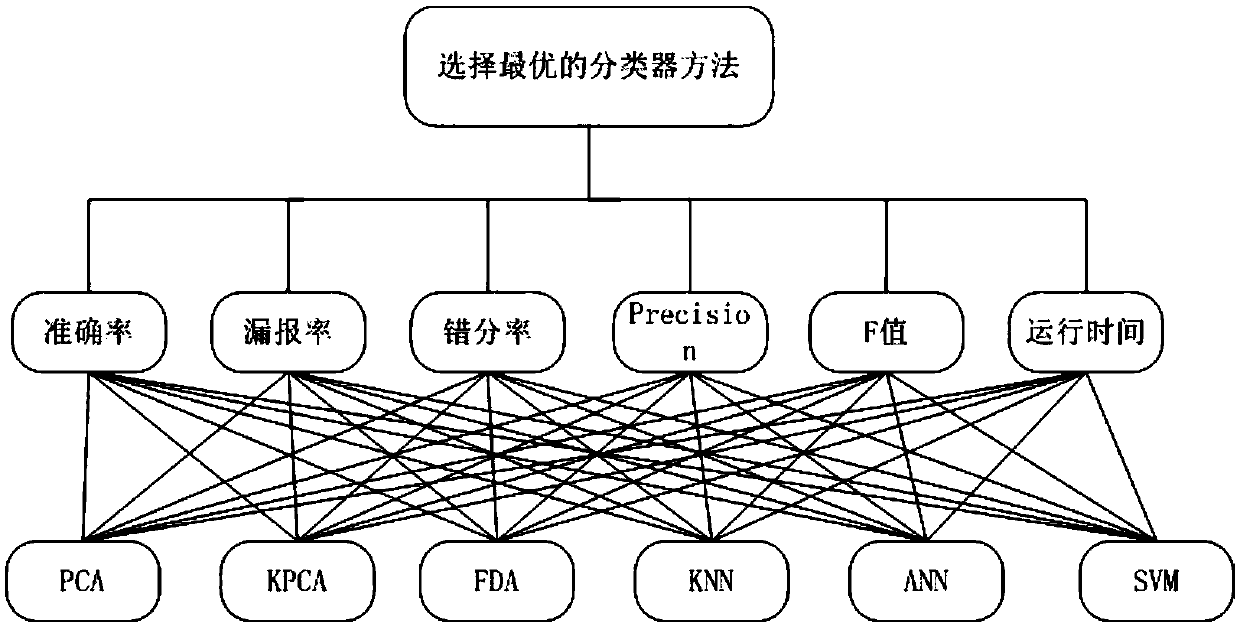

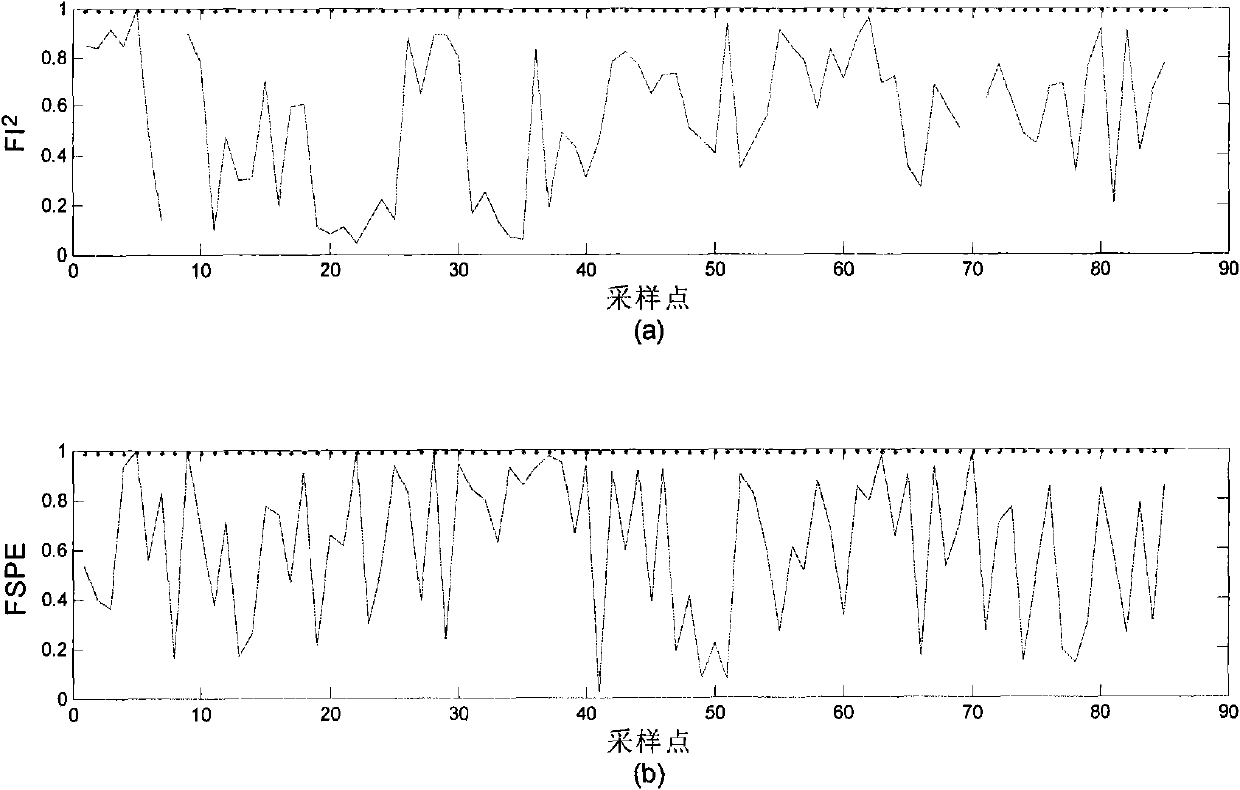

Fault detection method based on analytic hierarchy process and weighted vote decision fusion

ActiveCN106355030AImprove monitoring effectFacilitates automated implementationCharacter and pattern recognitionInformaticsData setAlgorithm

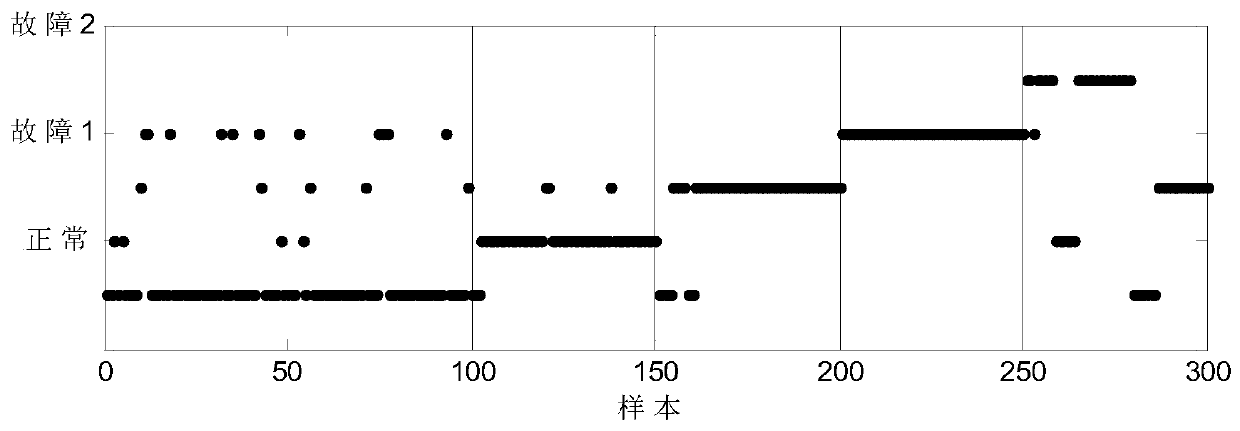

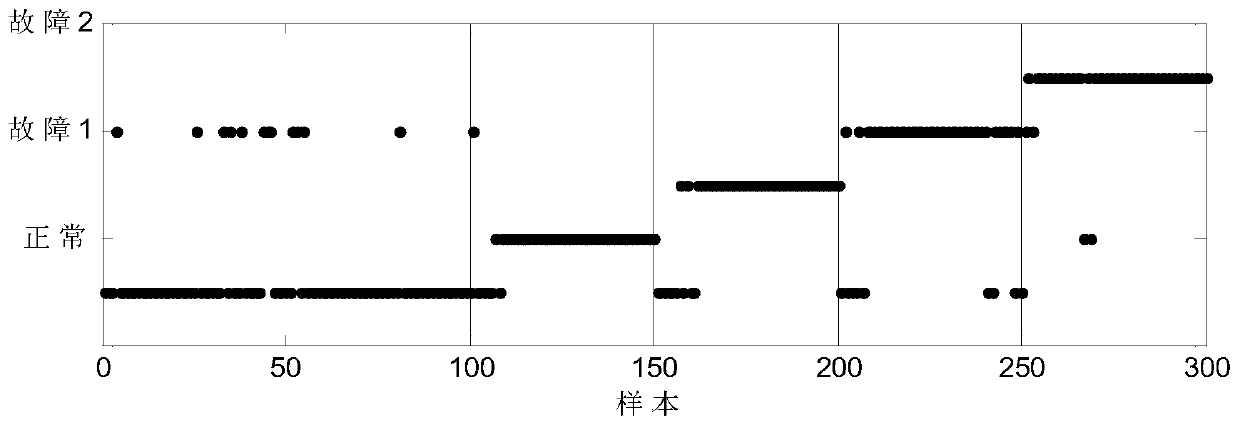

The invention discloses a fault detection method based on an analytic hierarchy process and weighted vote decision fusion. According to the method, firstly, multiple classifiers are selected as fusion sub-classifiers, multiple classifier models are established through a training data set, corresponding evaluation indexes are obtained according to the classification result of each classifier, and then multiple classifiers are scored and sequenced with the analytic hierarchy process, so that each classifier is endowed with the corresponding weight. Finally, multiple classifier decision results are integrated with a weighted vote fusion method, and the final fault detection result is obtained. Compared with other methods at present, the fault detection method has the advantages that the monitoring effect of the industrial process is improved, mastering and operation confidence of a process operator for the process are enhanced, the limitation of single fault detection methods is overcome to a great extent, and automatic implementation of the industrial process is better facilitated.

Owner:ZHEJIANG UNIV

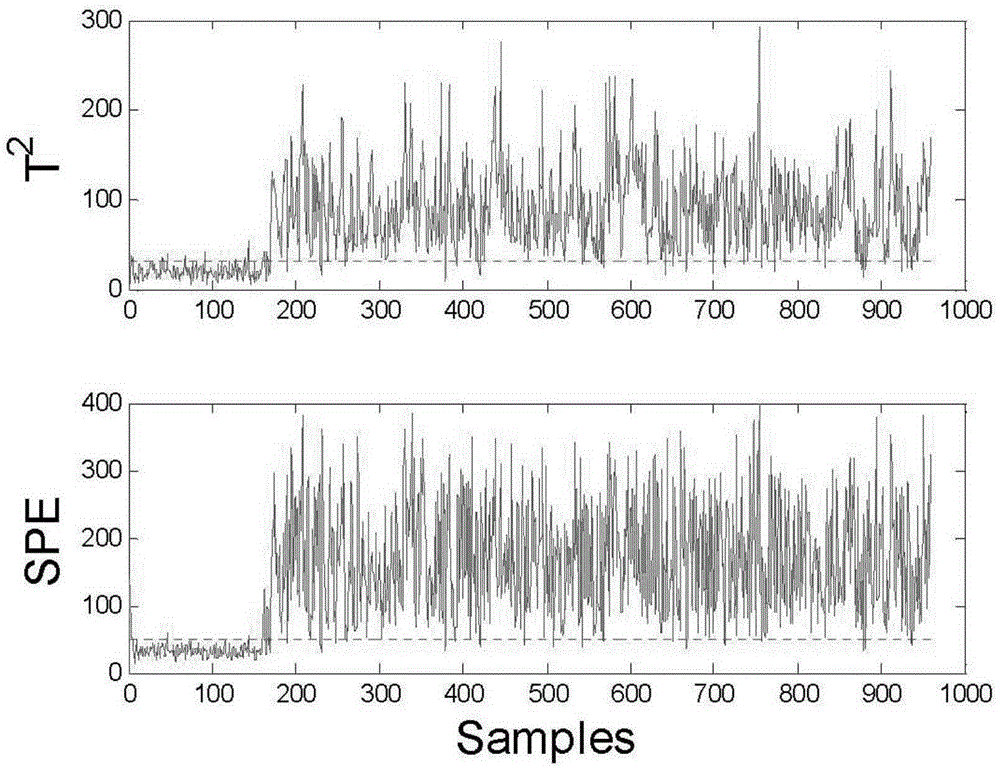

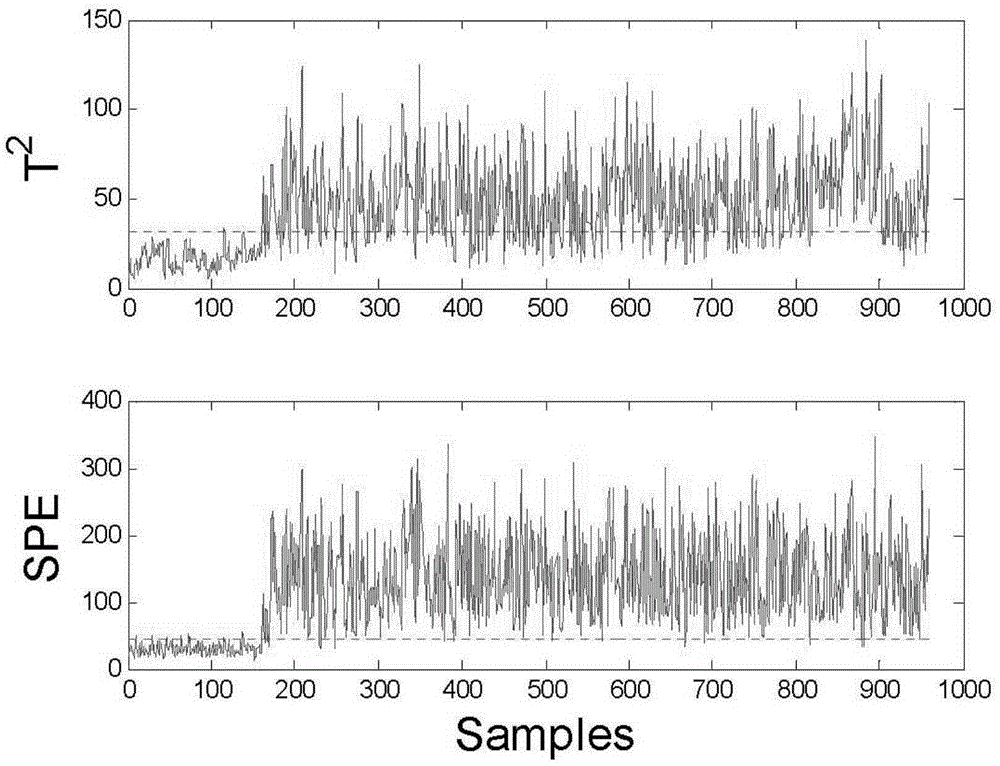

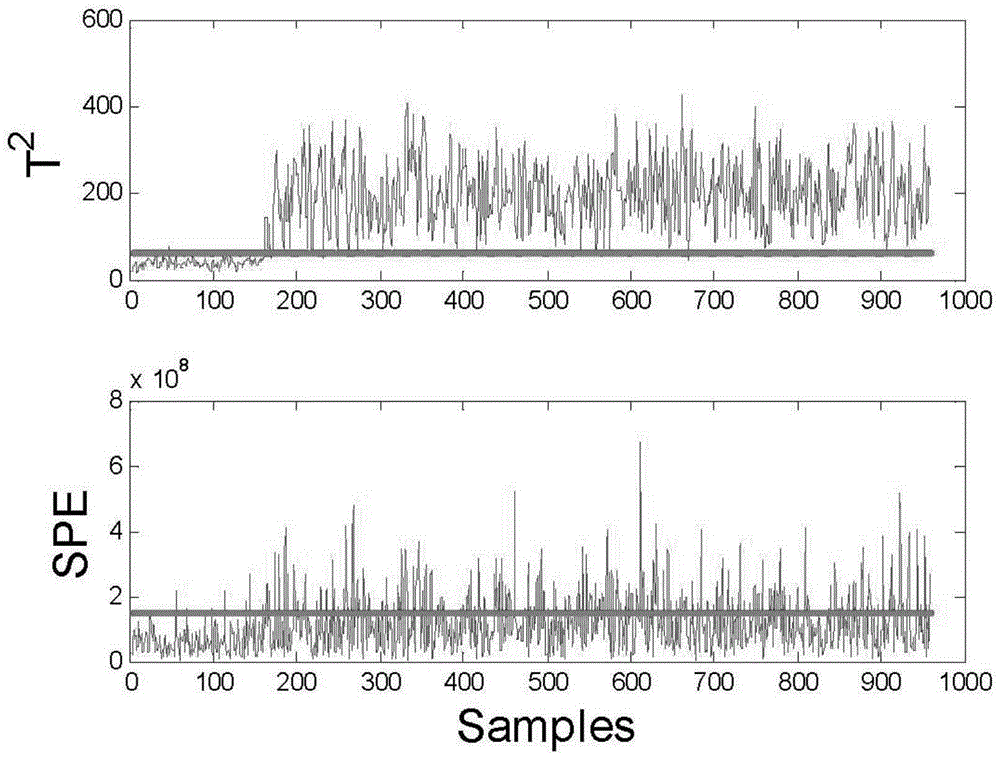

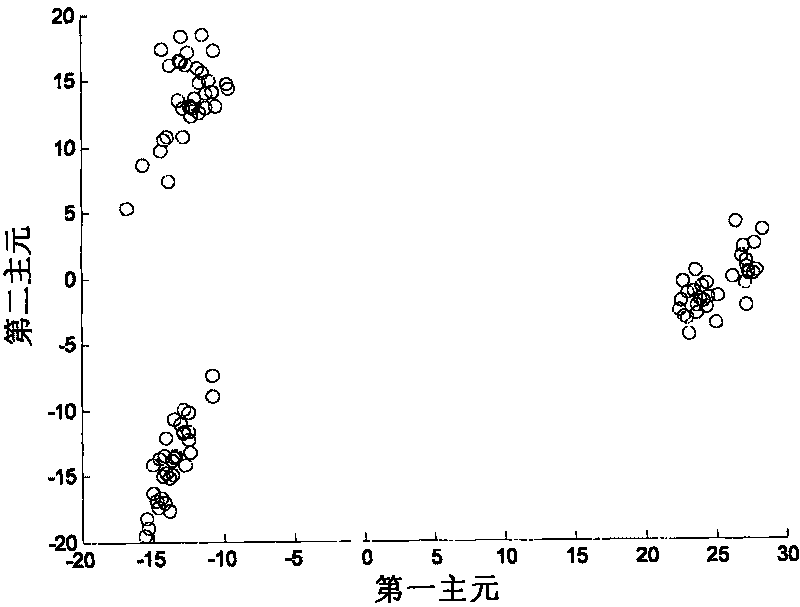

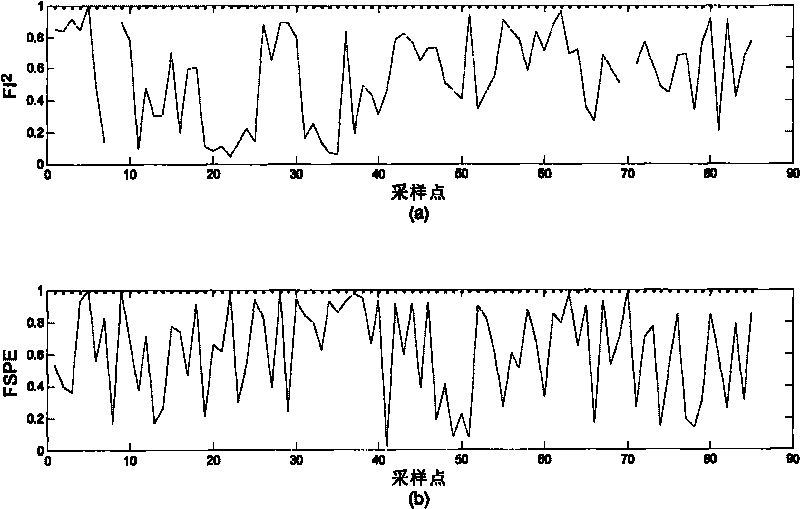

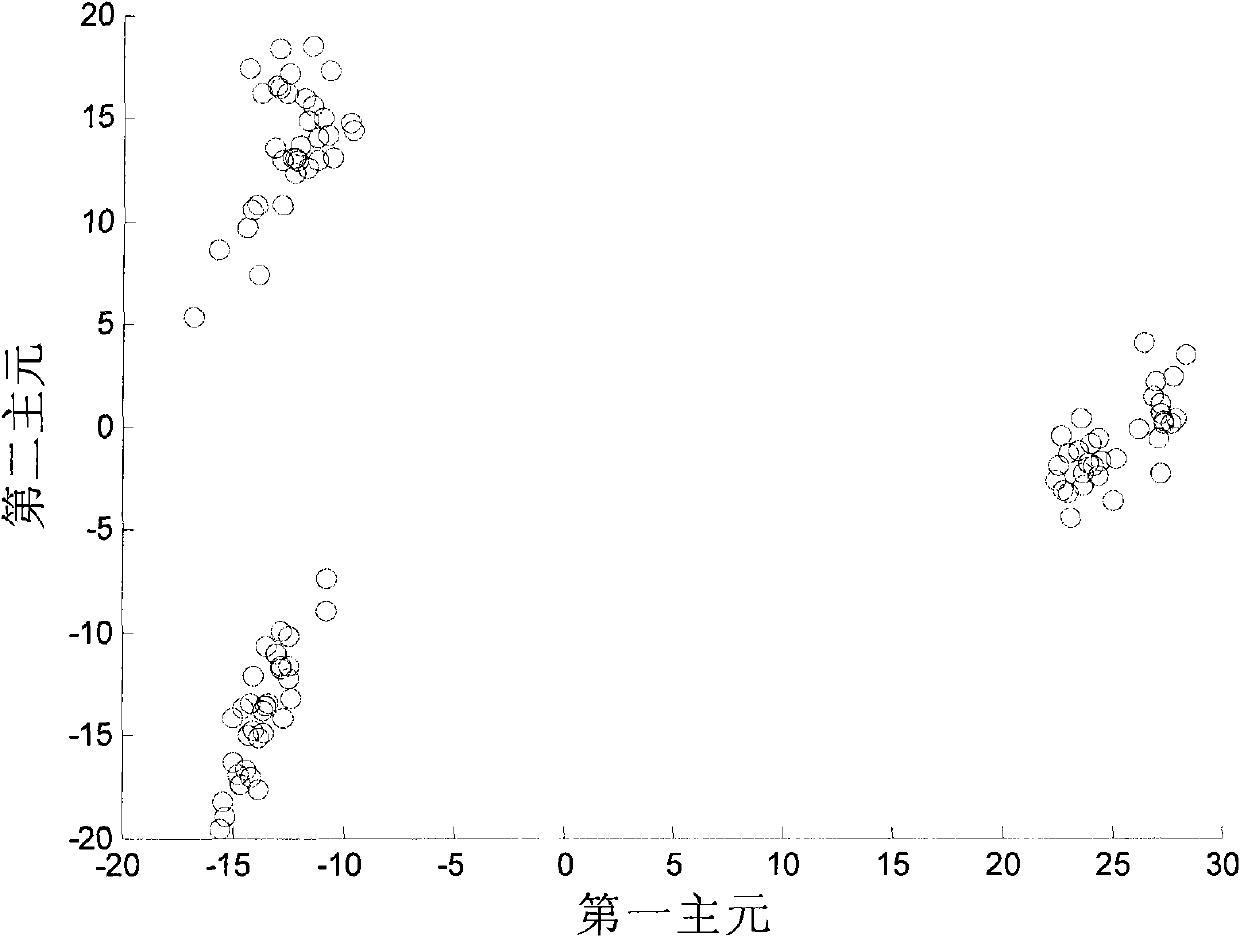

Industrial process fault detection method based on autoregression dynamic hidden variable model

InactiveCN105404280AEasy to detectFacilitates automated implementationProgramme controlElectric testing/monitoringExpectation–maximization algorithmProcess dynamics

The invention relates to an industrial process fault detection method based on an autoregression dynamic hidden variable model. According to the method, by use of data at a normal operation state in an industrial process, a dynamical process model with universality is established, and the model predicts a model structure through a Kalman filter and a smoother and an expectation maximization algorithm, such that dynamical and static coupling relation of industrial data can be effectively extracted; and then, based on dynamic and static noise of the dynamic model, a corresponding monitoring statistical amount is constructed, and a final fault detection result is obtained. Compared with other existing methods, the method provided by the invention can greatly improve the effects of industrial process dynamic modeling and fault detection, reduces the false alarm rate and the missed alarm rate of faults, improves the monitoring performance to a quite large degree, enhances the understanding capability and the operation confidence of process operators for the process and better facilitates automation implementation of the industrial process.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

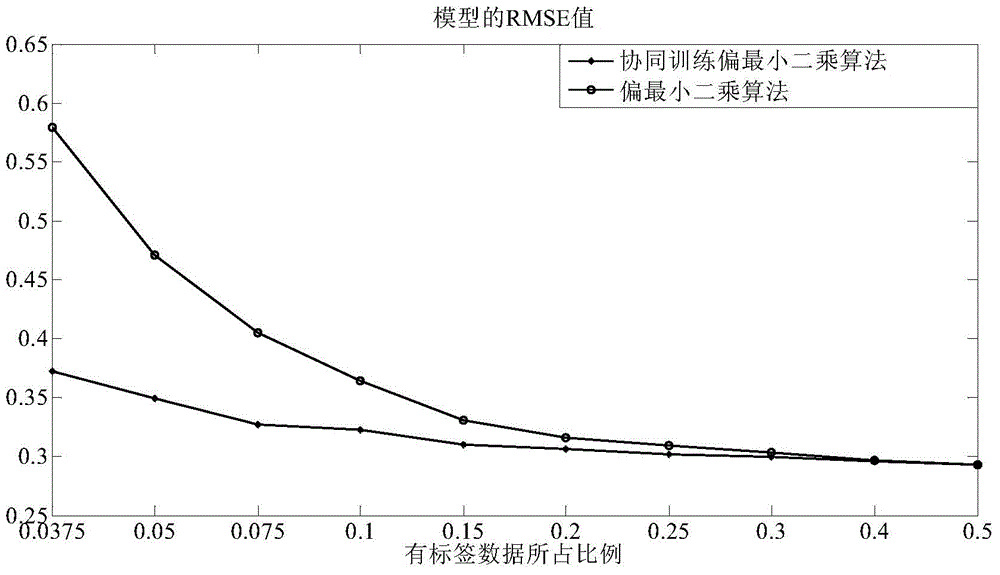

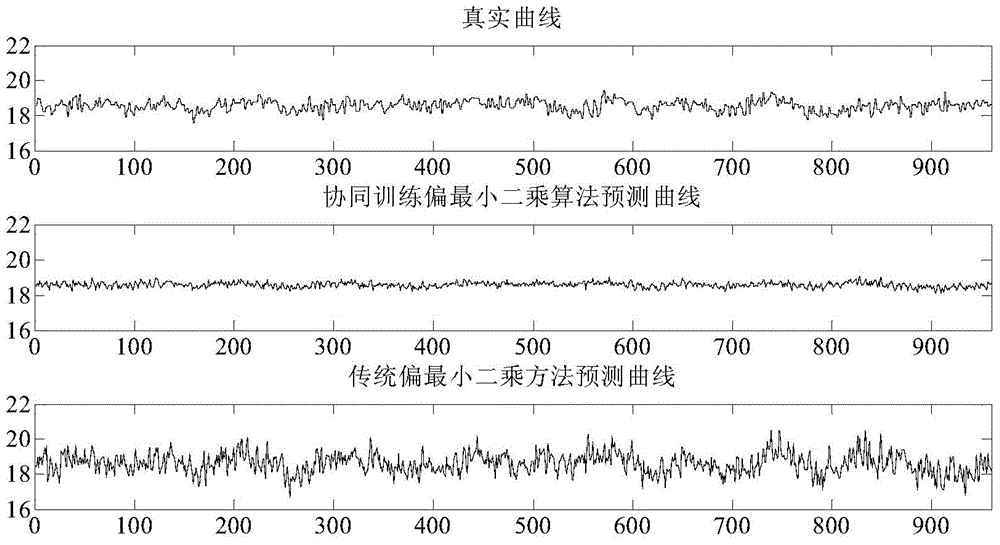

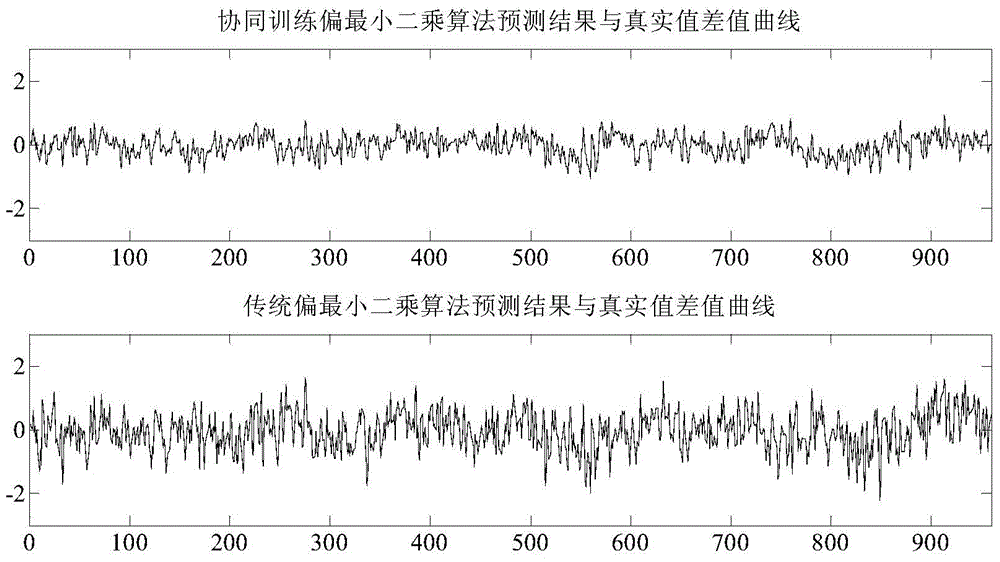

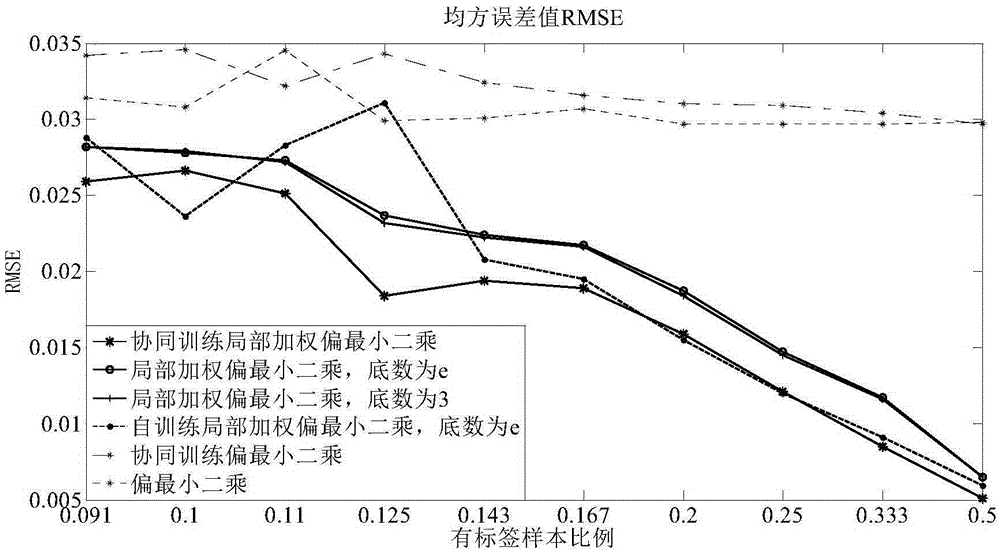

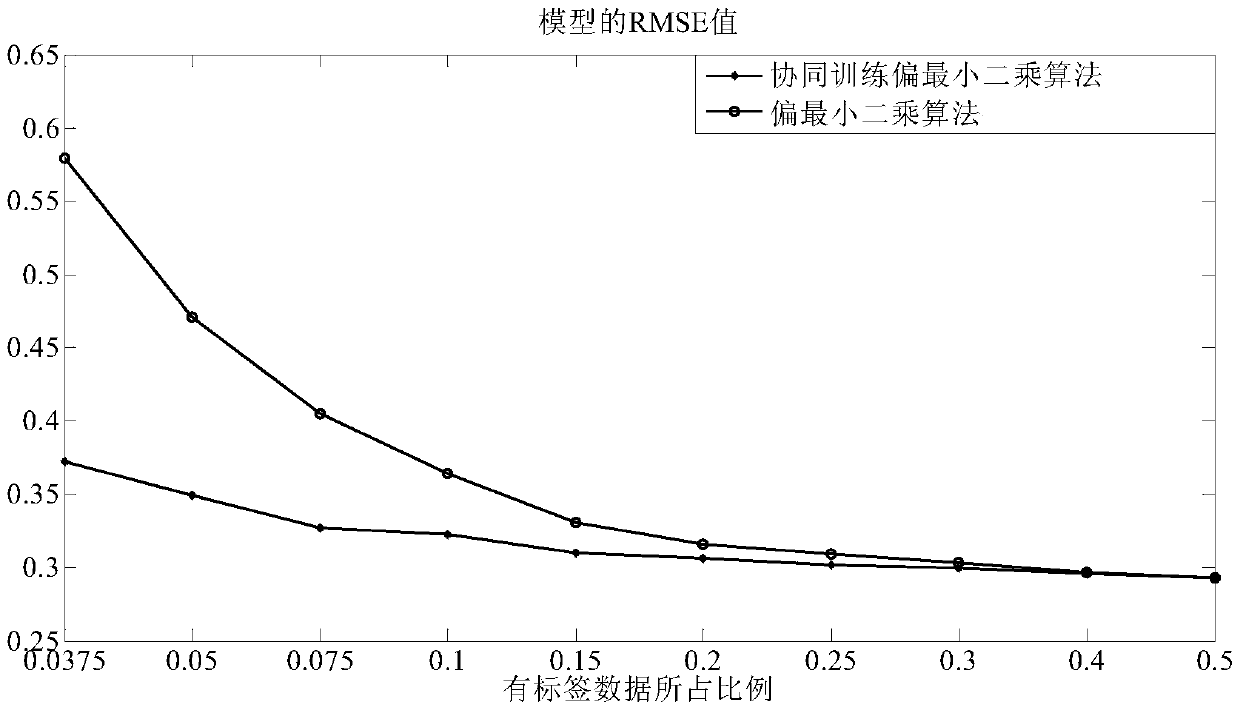

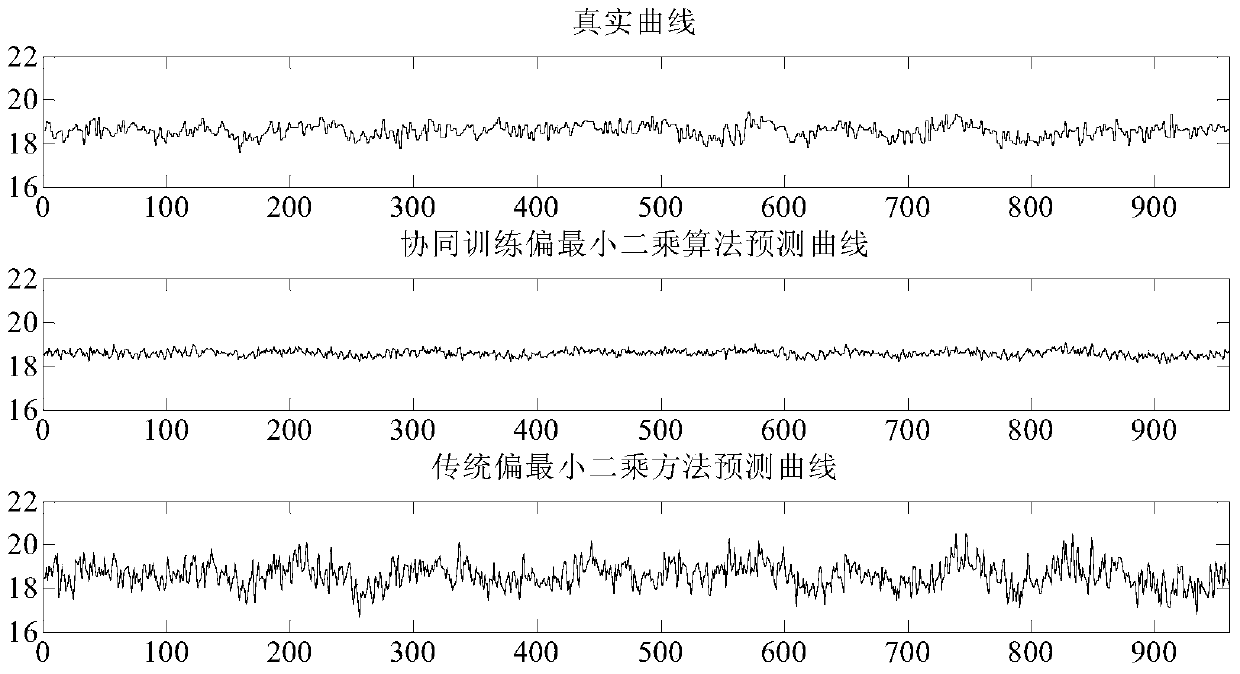

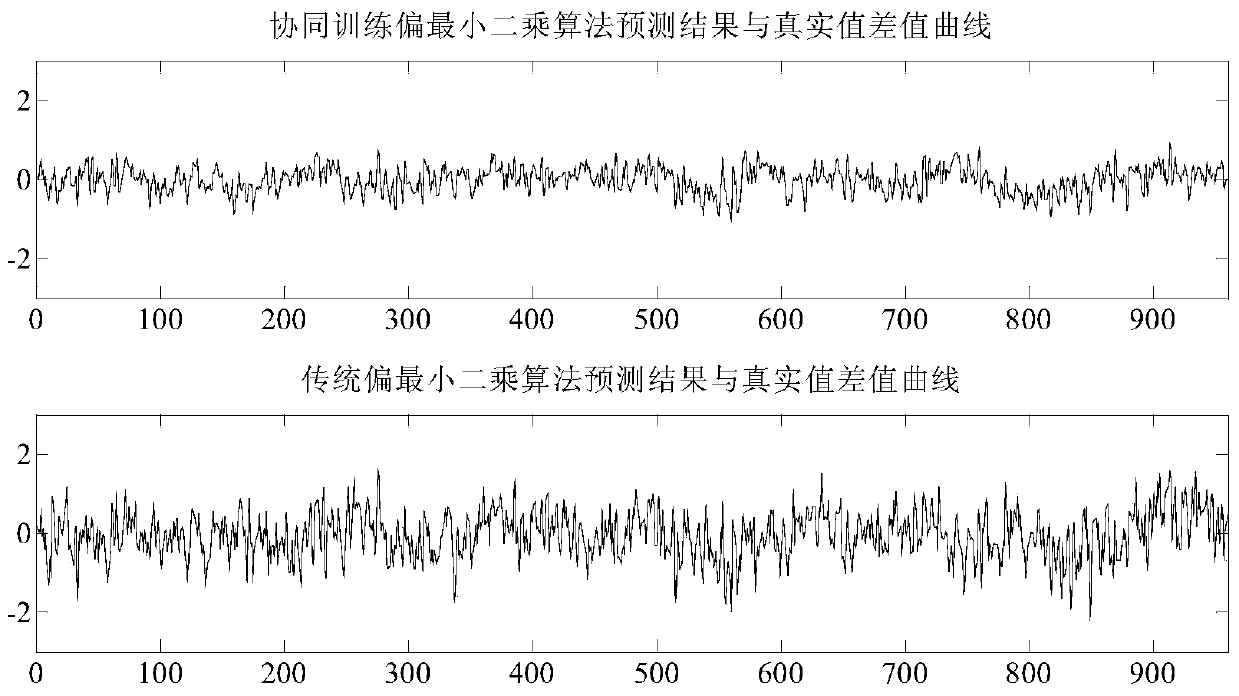

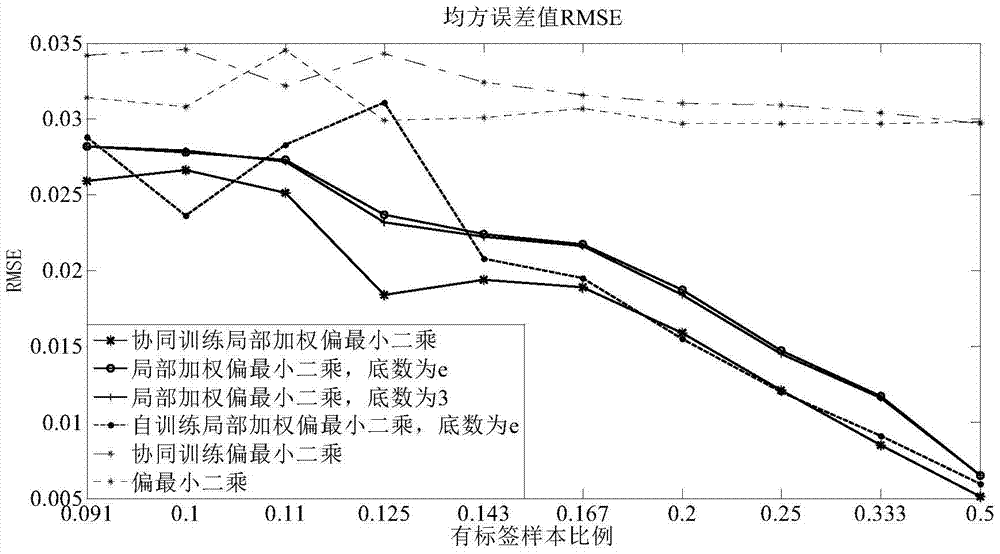

Industrial process soft measurement modeling method based on cooperative training partial least squares model

The invention discloses a soft measurement research method for the industrial production process under the condition that the number of available training samples is small, which is applied to carrying out soft measurement modeling under the condition that modeling data is small in amount and realizing prediction for product information. According to the invention, an effective linear prediction model is established by using a cooperative training based partial least squares learning method, a problem of low model precision under the condition that sampling data of the industrial production process is small in amount, and the predication accuracy and the performance of the model established in allusion to the process are improved, thereby enabling the industrial production process to be more reliable, and enabling the product quality to be more stable.

Owner:ZHEJIANG UNIV

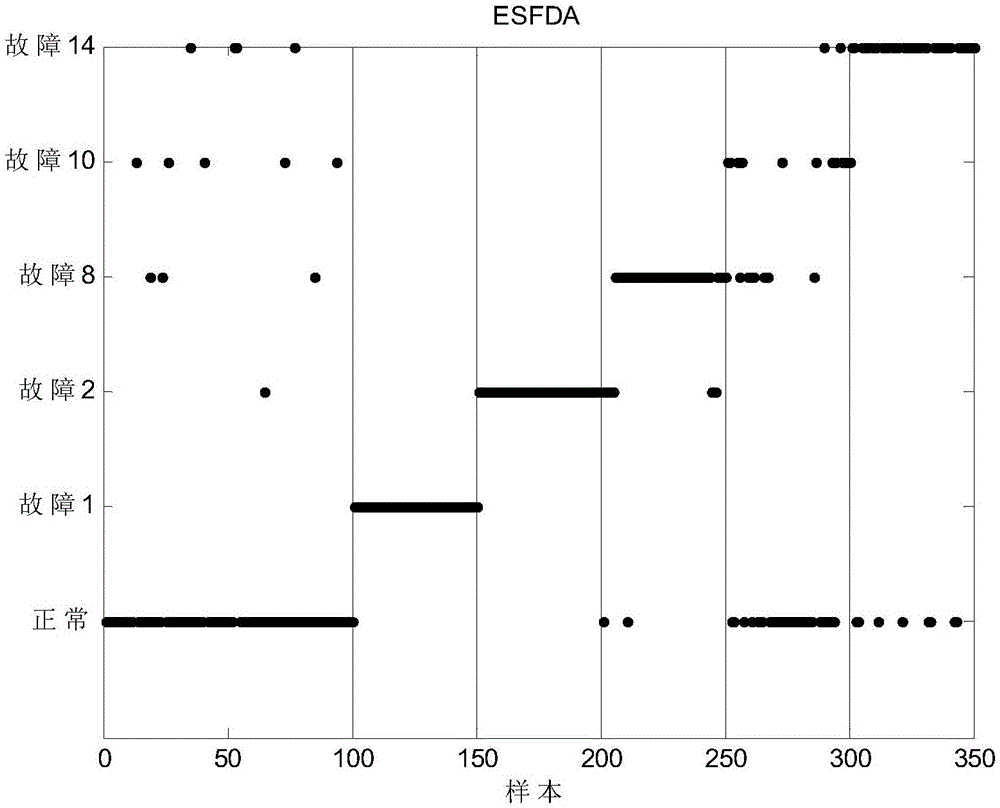

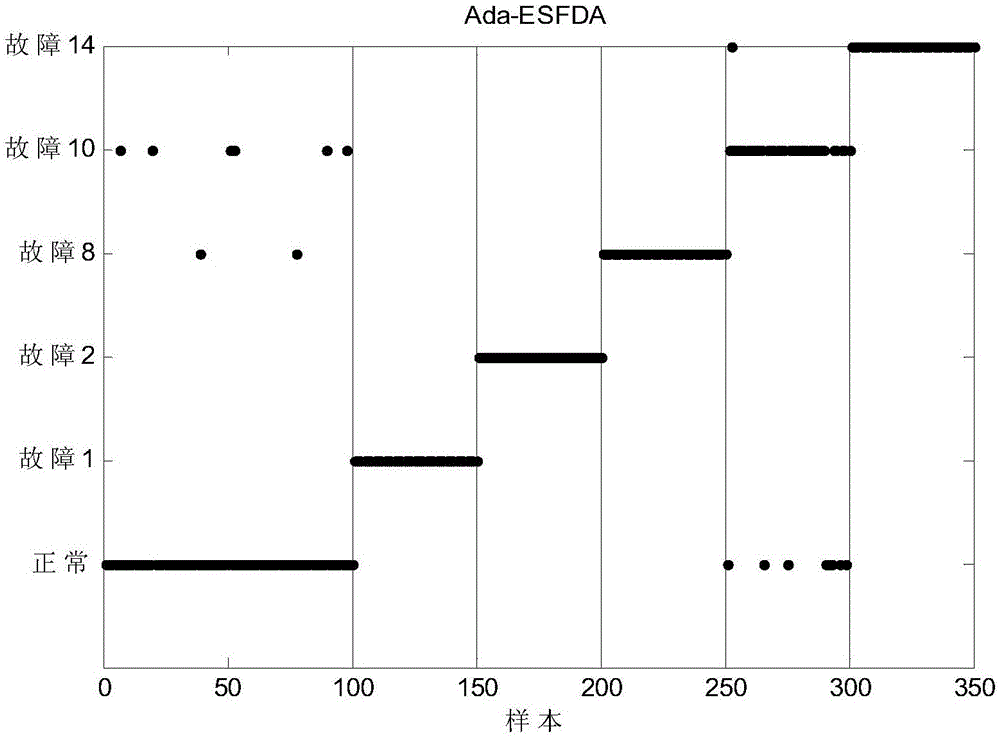

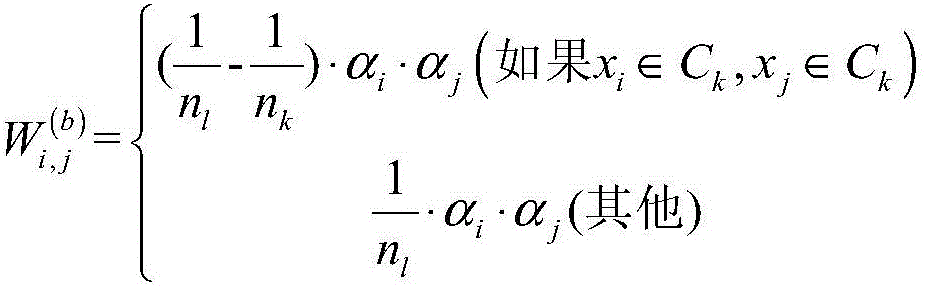

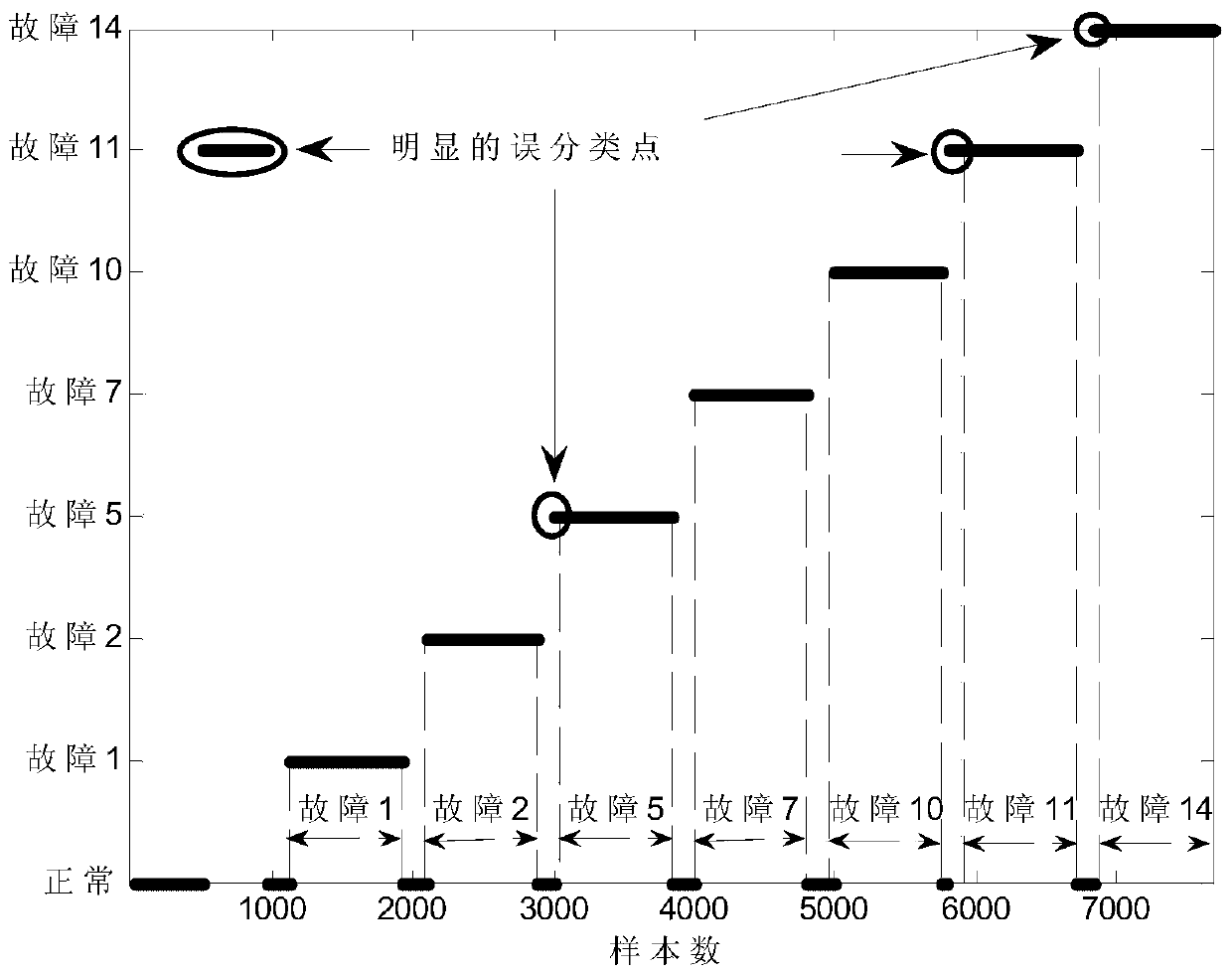

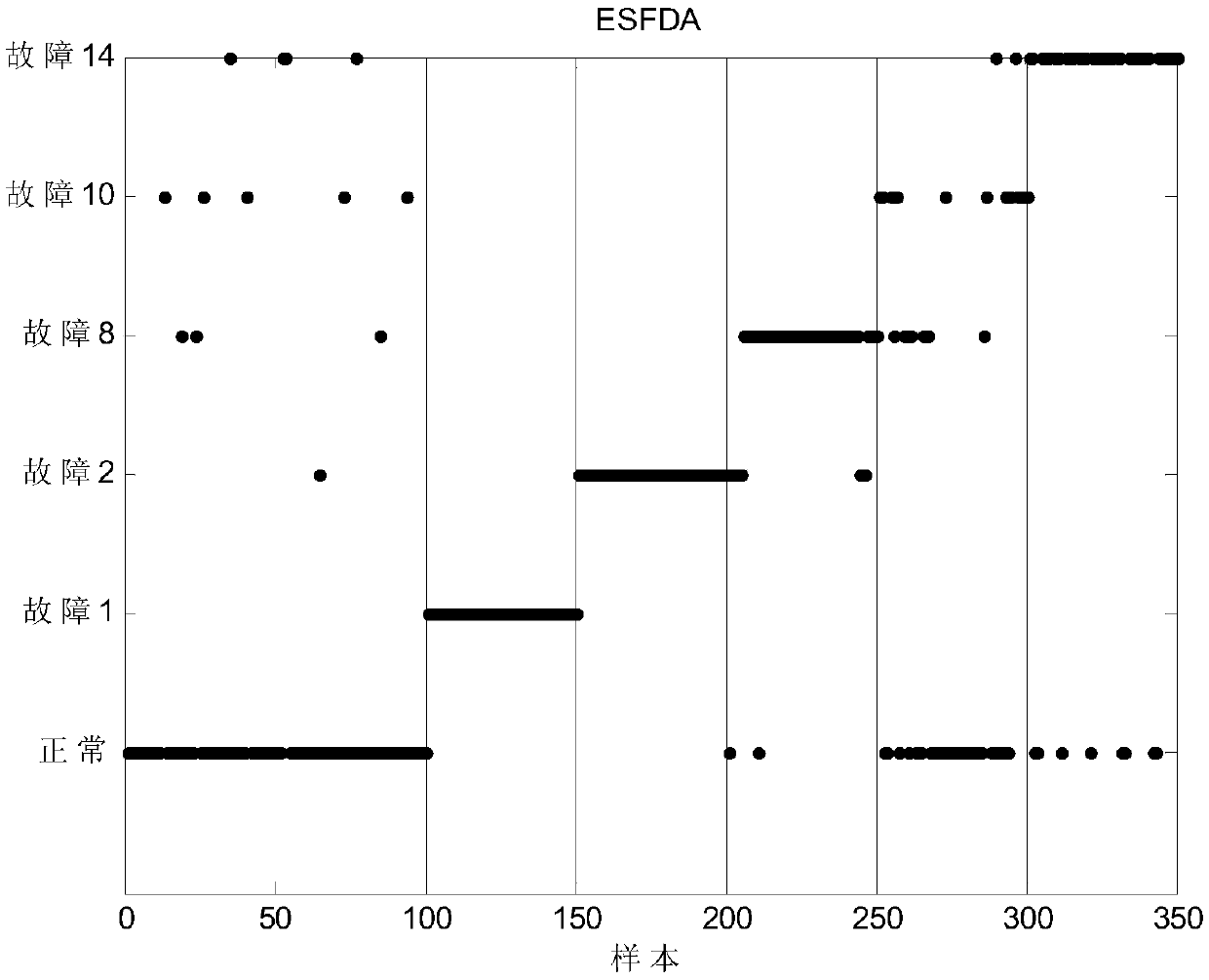

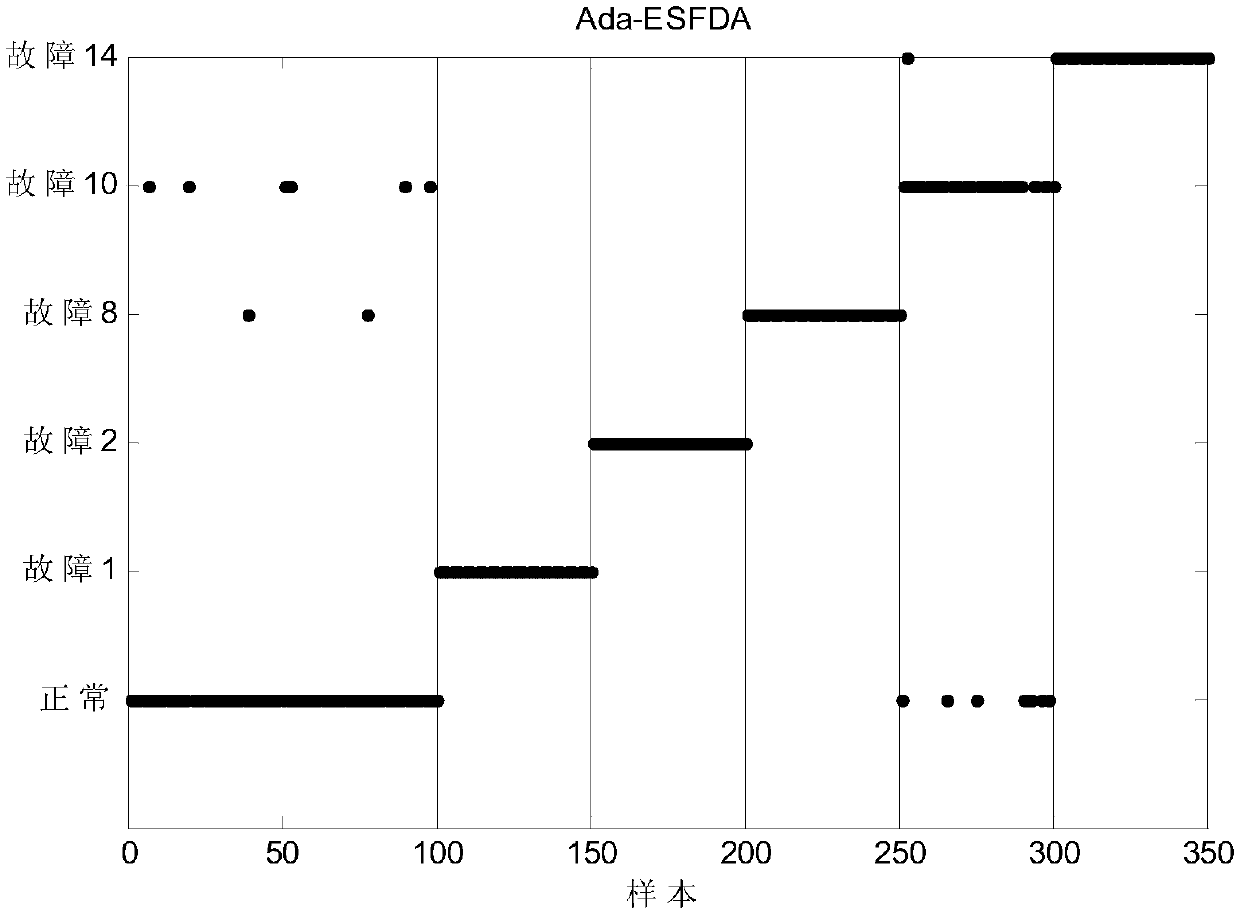

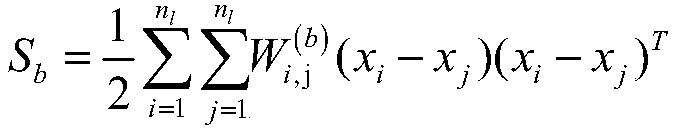

Fault classification method based on self-adaption integrated semi-supervision Fisher discrimination

InactiveCN106843195AImprove monitoring effectFacilitates automated implementationElectric testing/monitoringAlgorithmNear neighbor

The invention discloses an industrial process fault classification method based on self-adaption integrated semi-supervision Fisher discrimination. The method comprises the steps of when off-line modeling is conducted, firstly conducting off-line modeling on unlabeled data, and constituting a semi-supervision random training subset by combining labeled data with the unlabeled data; when iteration training is conducted on a sub classifier each time, conducting semi-supervision Fisher dimensionality reduction to obtain a Fisher discrimination matrix, and obtaining a posterior probability matrix, a combined weight of the sub classifier and a sample weight of the labeled data during next time iteration with the labeled sample data after dimensionality reduction according to a Bayesian statistics method; adopting the posterior probability matrix of the labeled data and a label of the matrix as a training set of a fusion algorithm K near neighbor; during online classification, calling each sub classifier to obtain the posterior probability matrix of an online sample to be detected, and inputting the posterior probability matrix into a fusion K near neighbor classifier with the weight to obtain a final result. Compared with an existing method, the industrial process fault classification method based on the self-adaption integrated semi-supervision Fisher discrimination improves the fault classification result of an industrial process, and more facilitates automated implementation of the industrial process.

Owner:ZHEJIANG UNIV

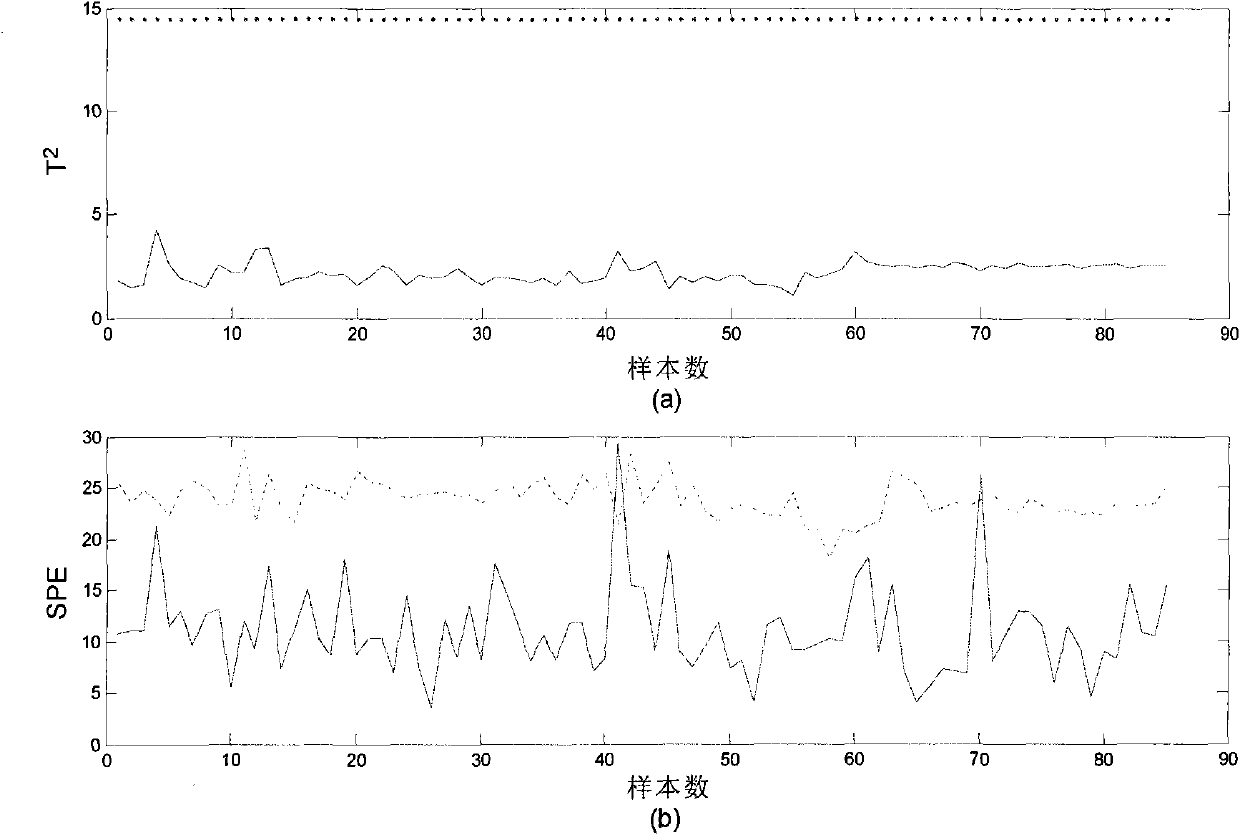

Semiconductor process monitoring method based on independent component analysis and Bayesian inference

InactiveCN101713983AImprove monitoring effectFacilitates automated implementationTotal factory controlProgramme total factory controlIndependent component analysisAnalysis method

The invention discloses a semiconductor process monitoring method based on independent component analysis and Bayesian inference, comprising the following step of: firstly, dividing working conditions according to the mixed data of the semiconductor process, conducting the independent component analysis for each working condition data, and establishing a corresponding independent component analysis model; and then integrating and combining the monitoring information under the different working conditions by a Bayesian inference method to obtain a final monitoring result. In addition, the invention can also acquire the working condition information of current monitoring data by a posterior probability analysis method, that is to say, the invention can judge that the current monitoring data is in what process operation working condition; compared with the present other methods, the invention can not only greatly enhance the monitoring effect of the semiconductor process, but also largely improve the dependence of the monitoring method on process knowledge and enhance the comprehensive ability and the operating confidence of process operators on the process, thereby being more beneficial to the implementation of the automation of the semiconductor process.

Owner:ZHEJIANG UNIV

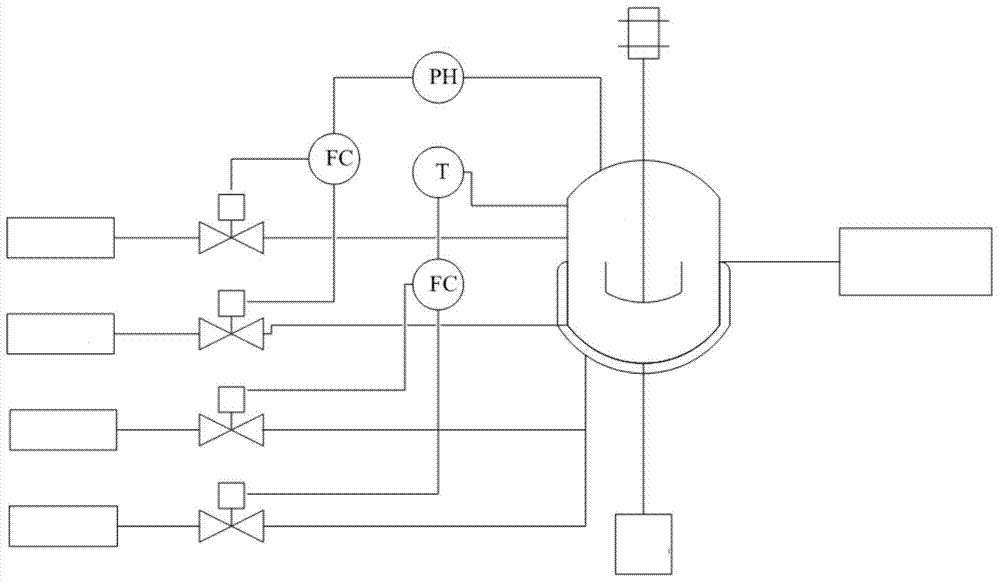

Control method of penicillin production process based on cooperative training local weighted partial least squares (LWPLS)

InactiveCN105425583AImprove predictive performanceHigh precisionAdaptive controlLearning methodsComputer science

The invention discloses a control method of a penicillin production process of cooperative training and Local Weighted Partial Least Squares (LWPLS), and the control method is used for soft measurement modeling under the condition that the quantity modeling data is relatively small and realizing prediction of product information of a penicillin production process. According to the control method, an effective linear prediction model is established by using a cooperative training-based local weighted partial least squares learning method, the problem of low model precision under the condition that the quantity of sampling data of the penicillin production process is too small is overcome, and the predication accuracy and the performance of the model established directing at the process are improved, thereby enabling the penicillin production process to be more reliable, and enabling the product quality to be more stable.

Owner:ZHEJIANG UNIV

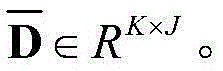

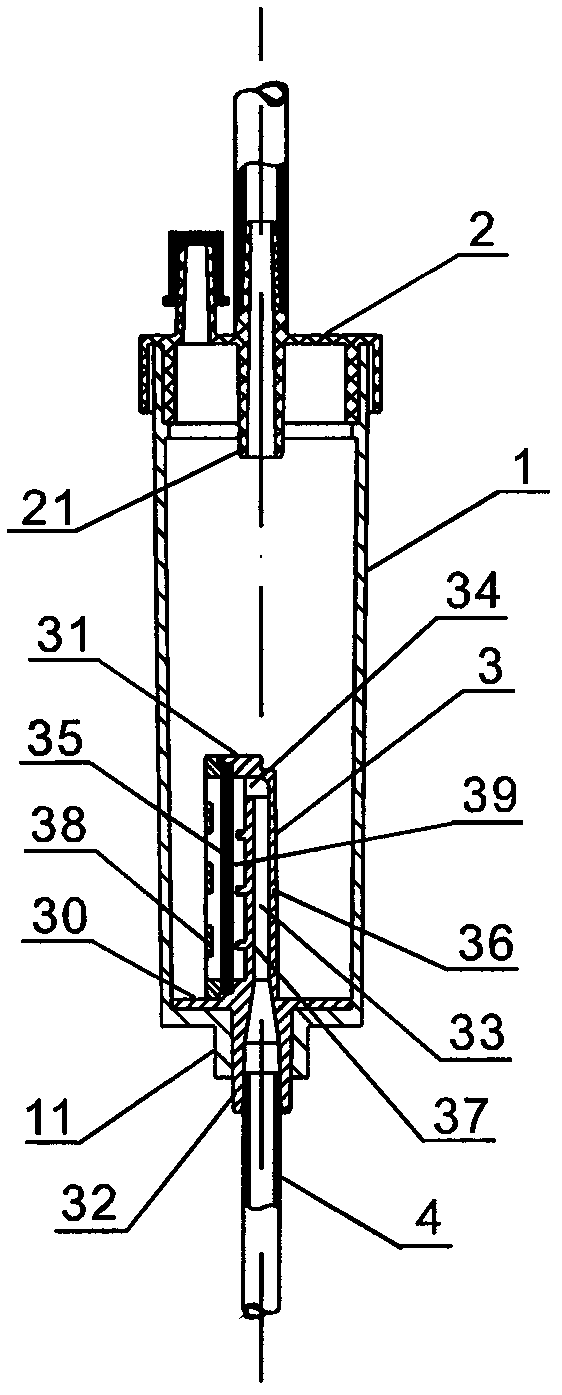

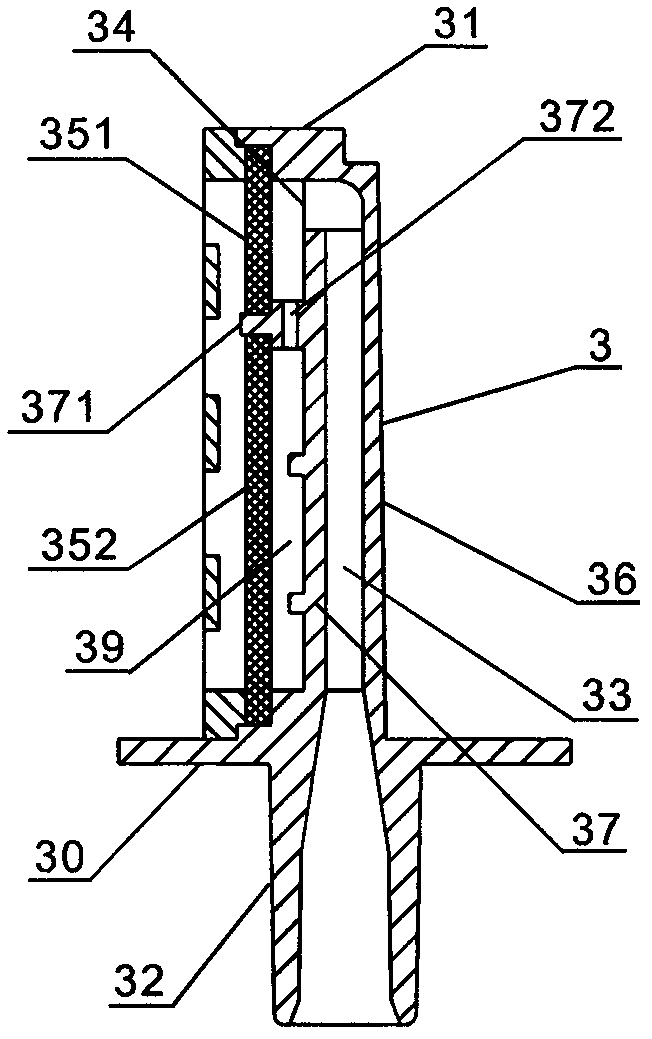

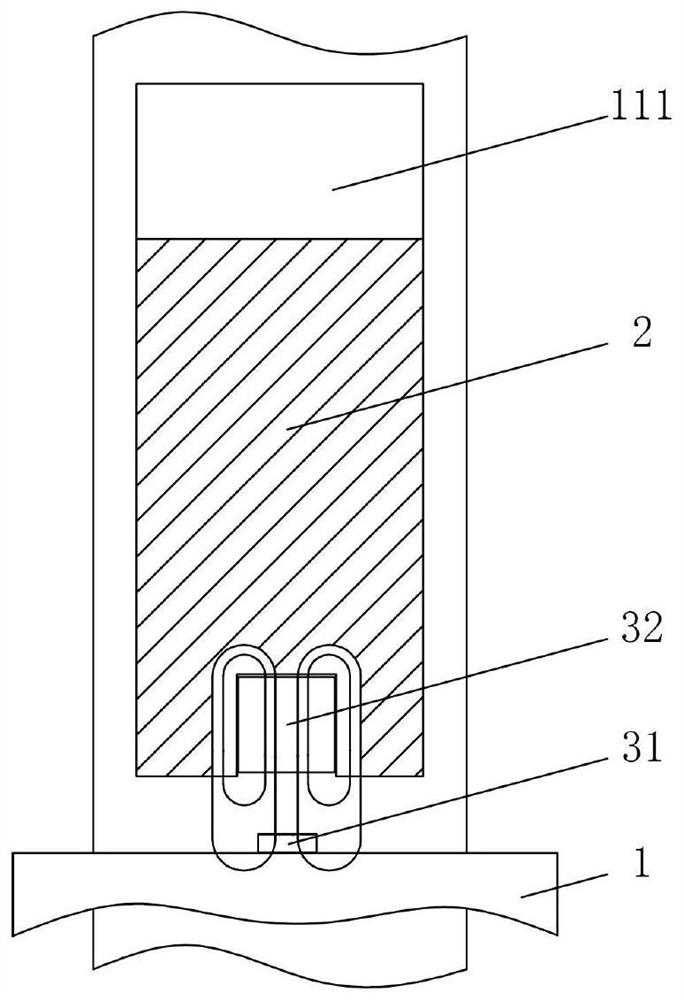

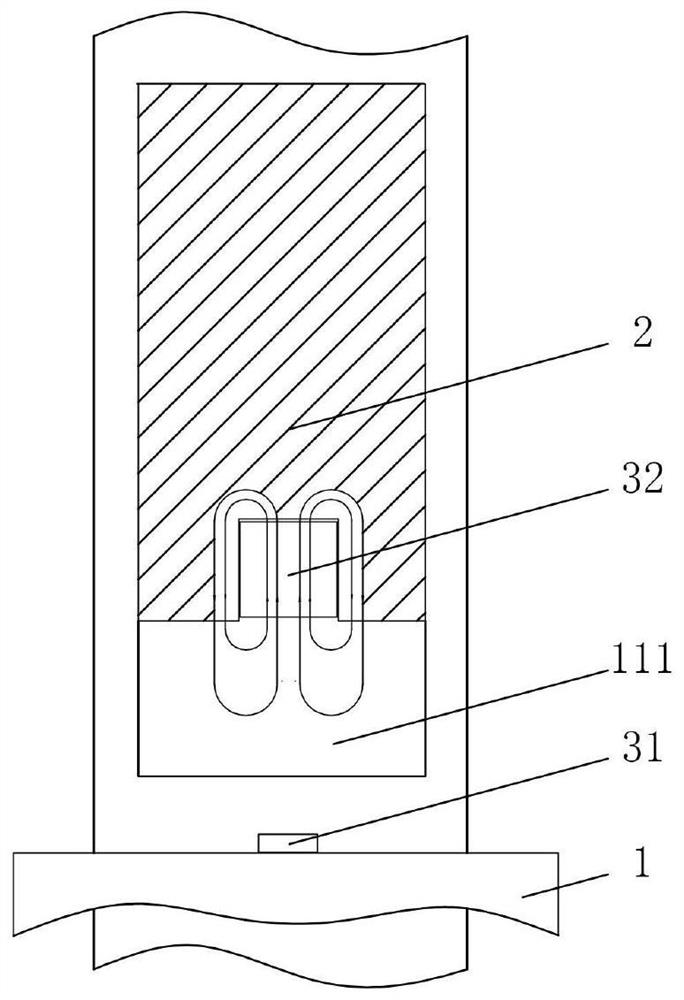

Automatic exhausting and liquid stopping multiple-effect infusion set

The invention relates to the technical field of medical equipment, in particular to an automatic exhausting and liquid stopping multiple-effect infusion set. The bottom of a dripping hopper is provided with an exhaust filter pipe sealed with a vertical filter membrane of which the bubble point pressure of 7.85-25.0kPa; the vertical filter membrane is gradually submersed when liquid is injected, so that a mode that the liquid is accumulated at the lower end and gas is exhausted at the upper end is realized; and by combining the special structure of the exhaust filter pipe, the multiple-effect aims of automatically exhausting, filtering a liquid medicine, eliminating bubbles and automatically stopping the liquid are skillfully fulfilled.

Owner:李林风

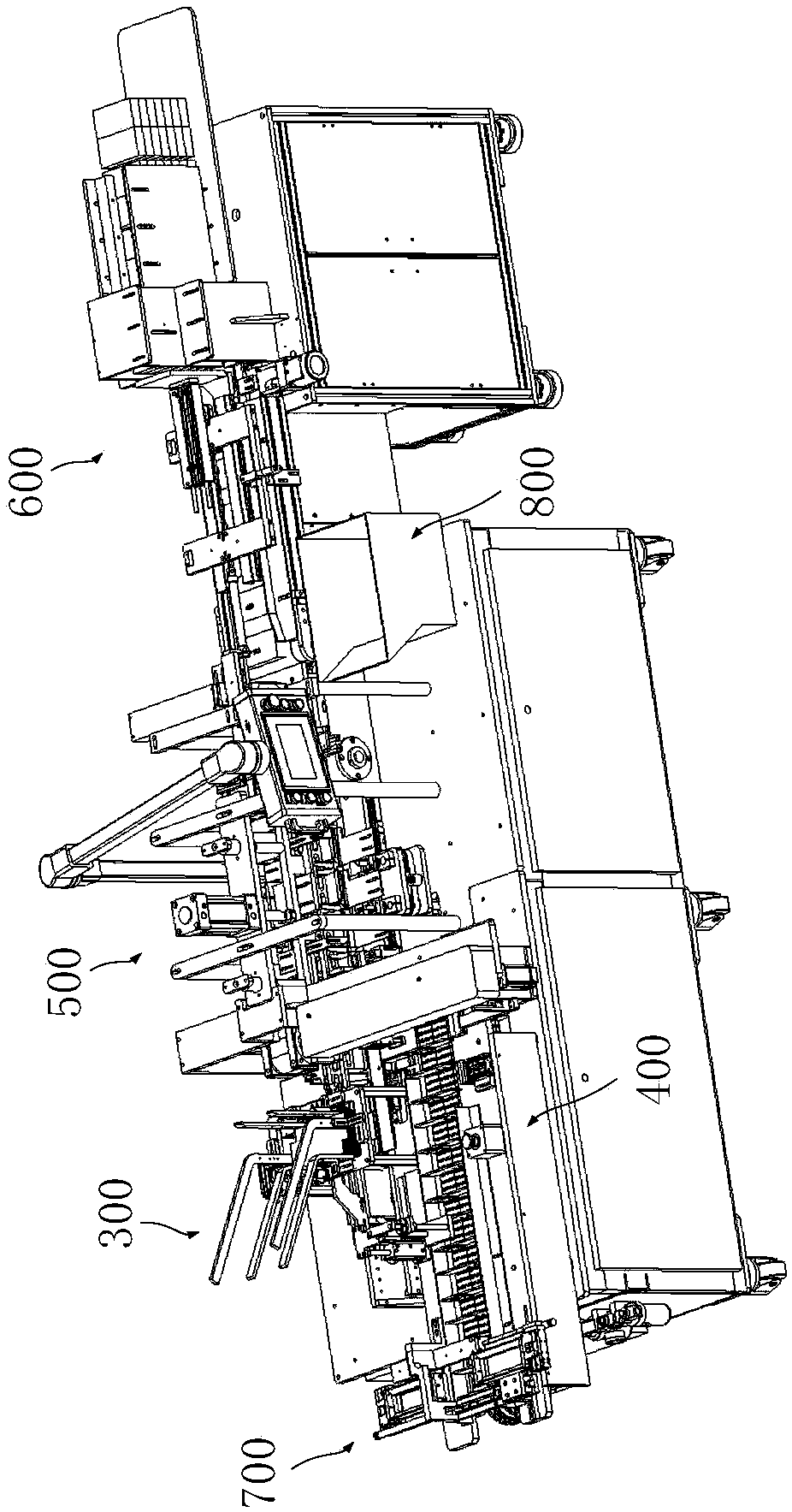

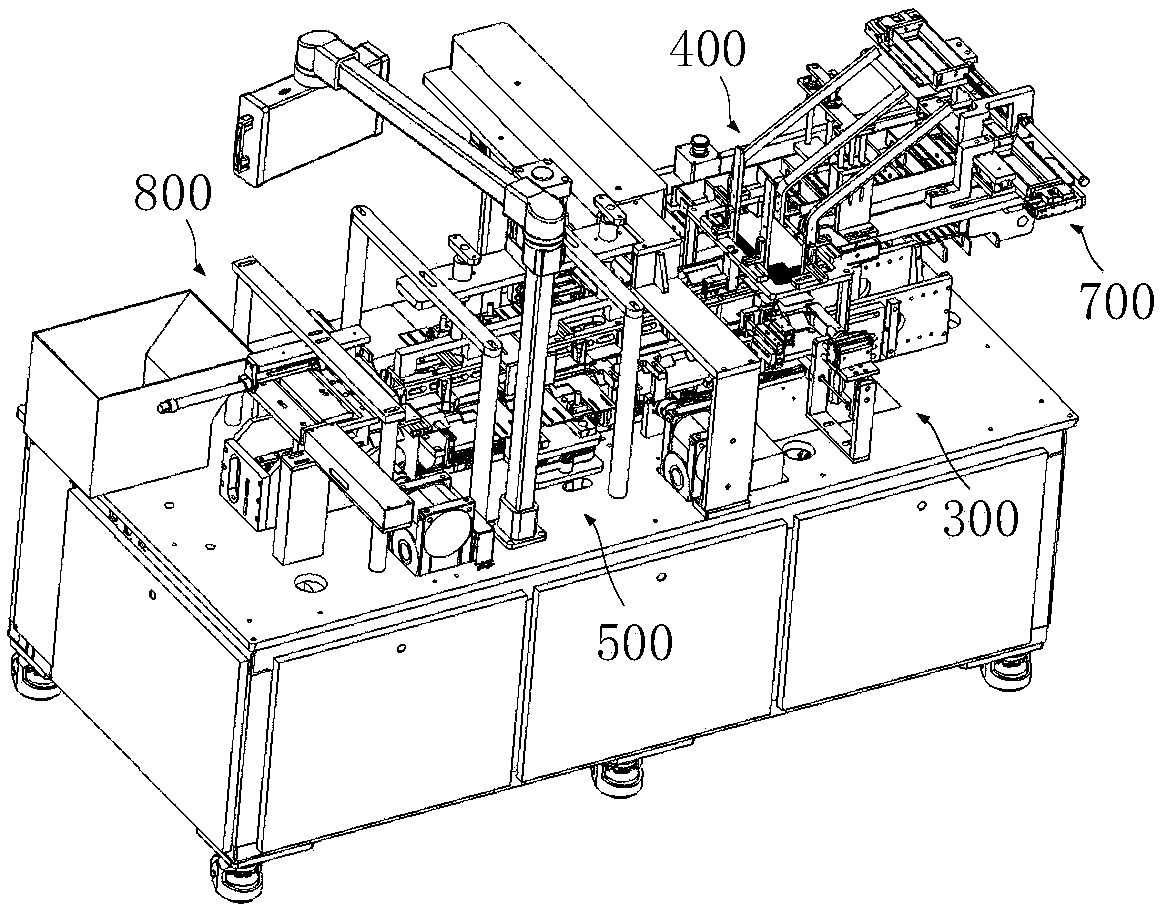

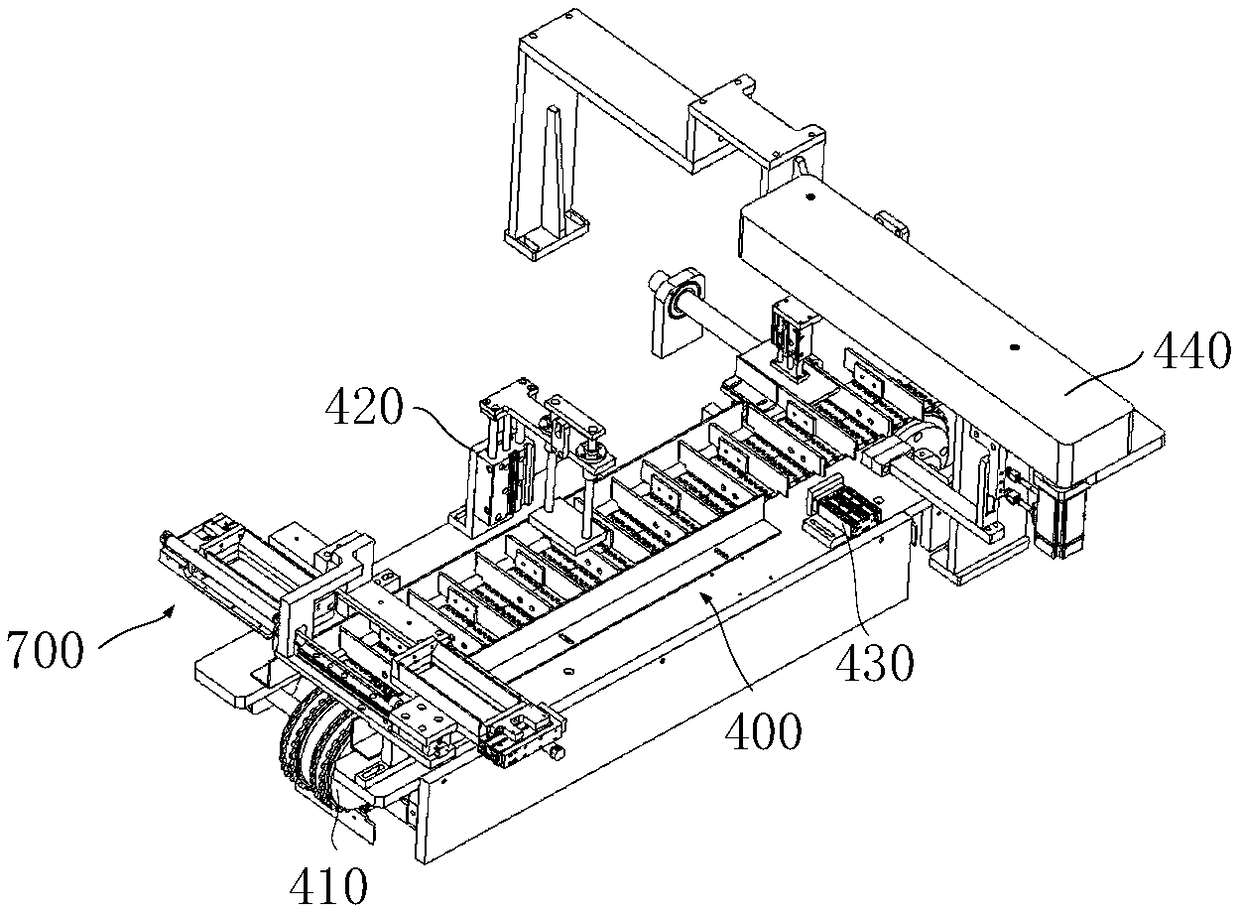

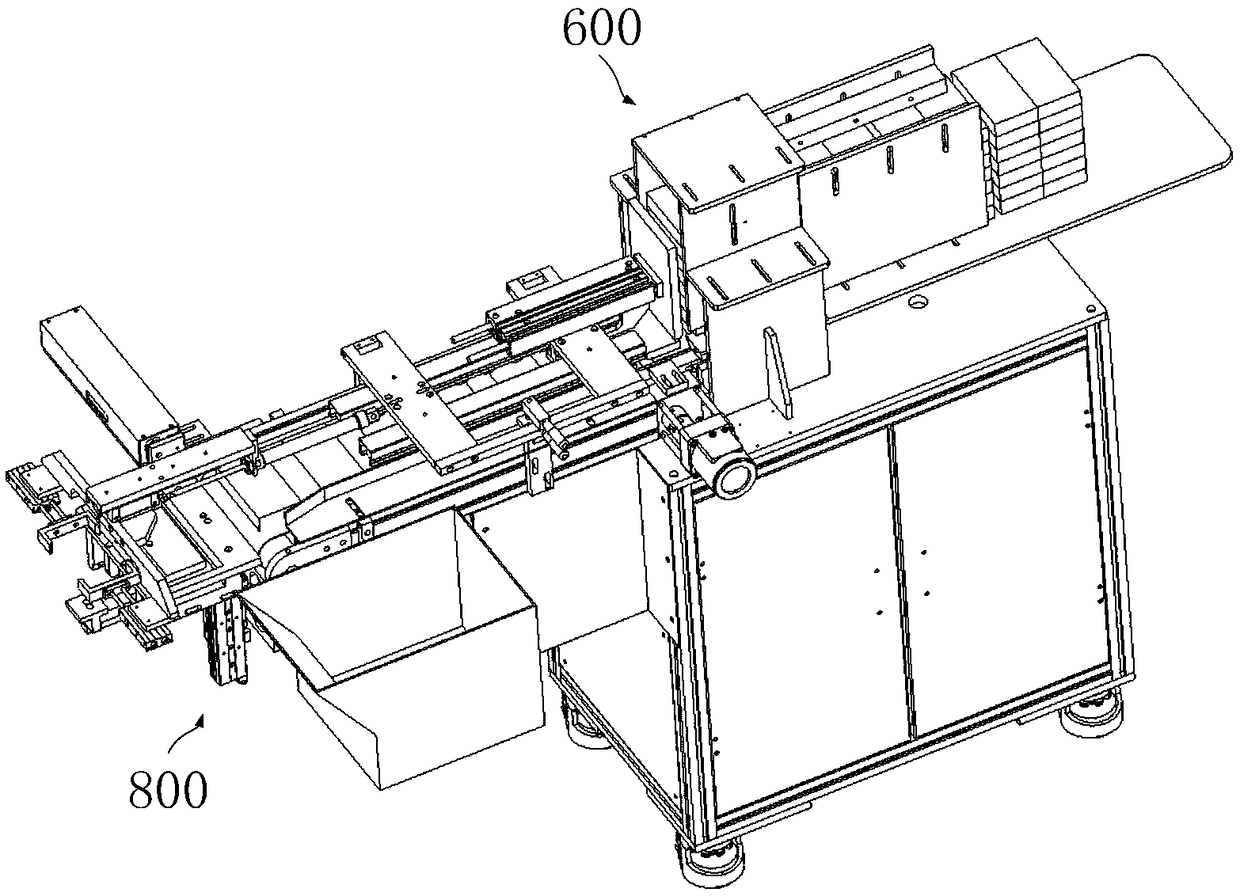

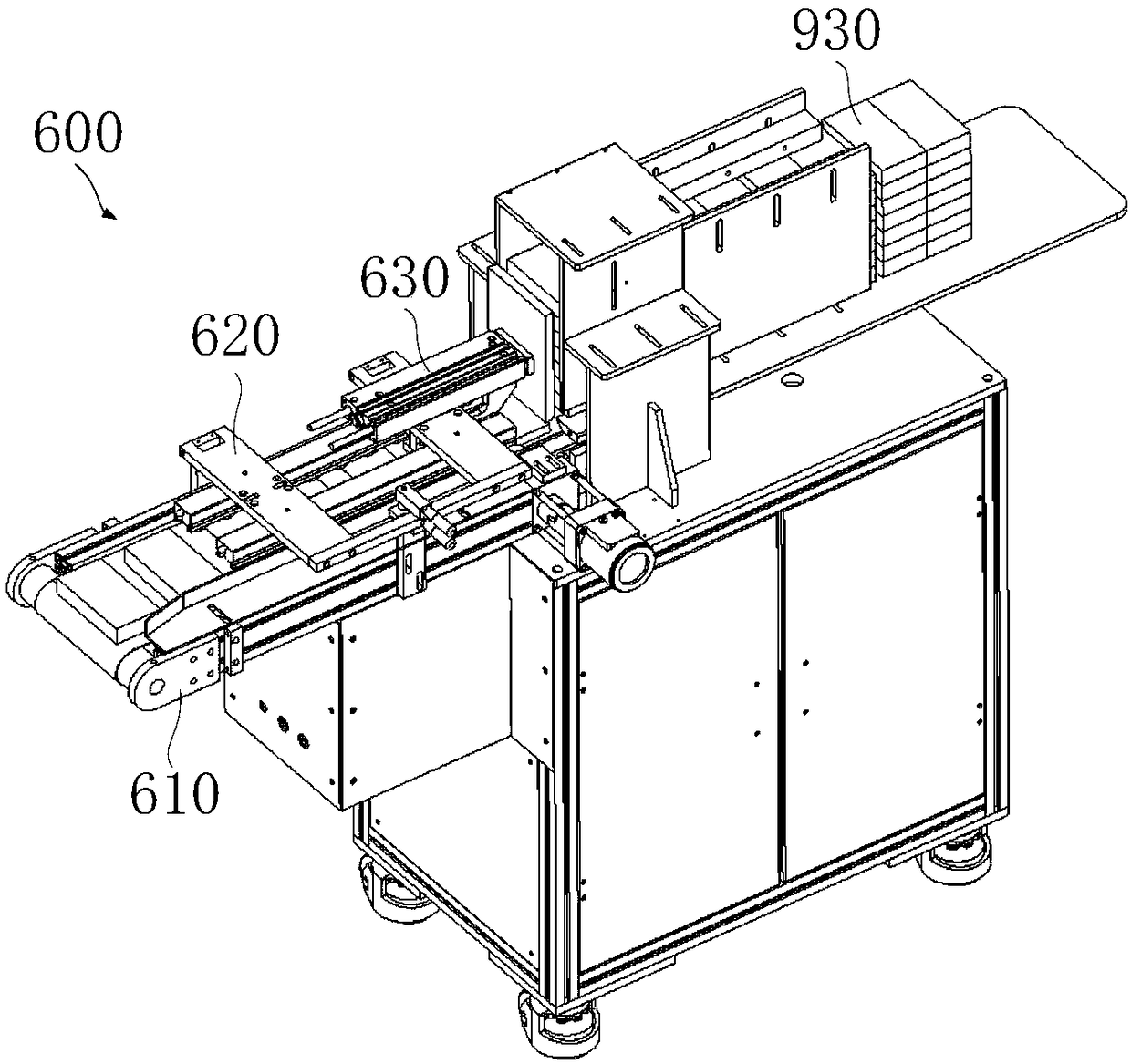

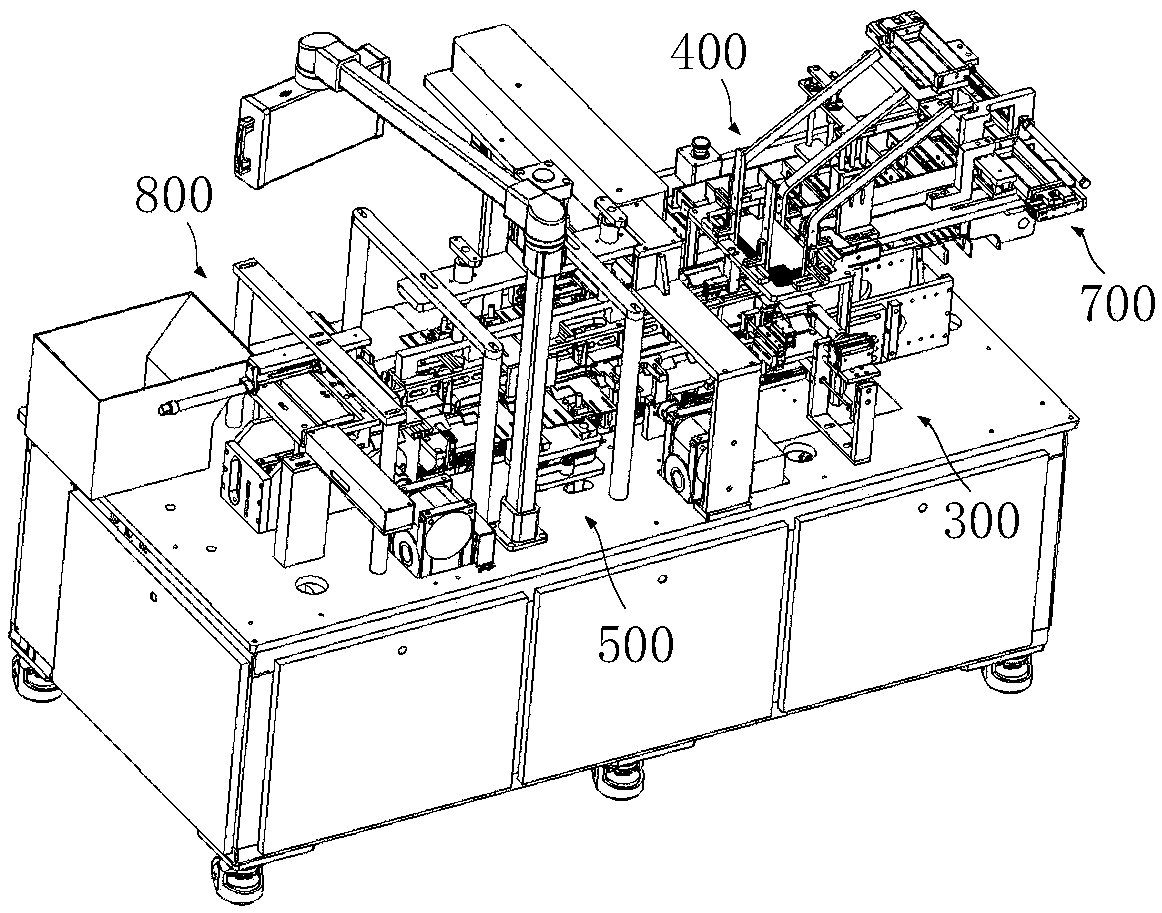

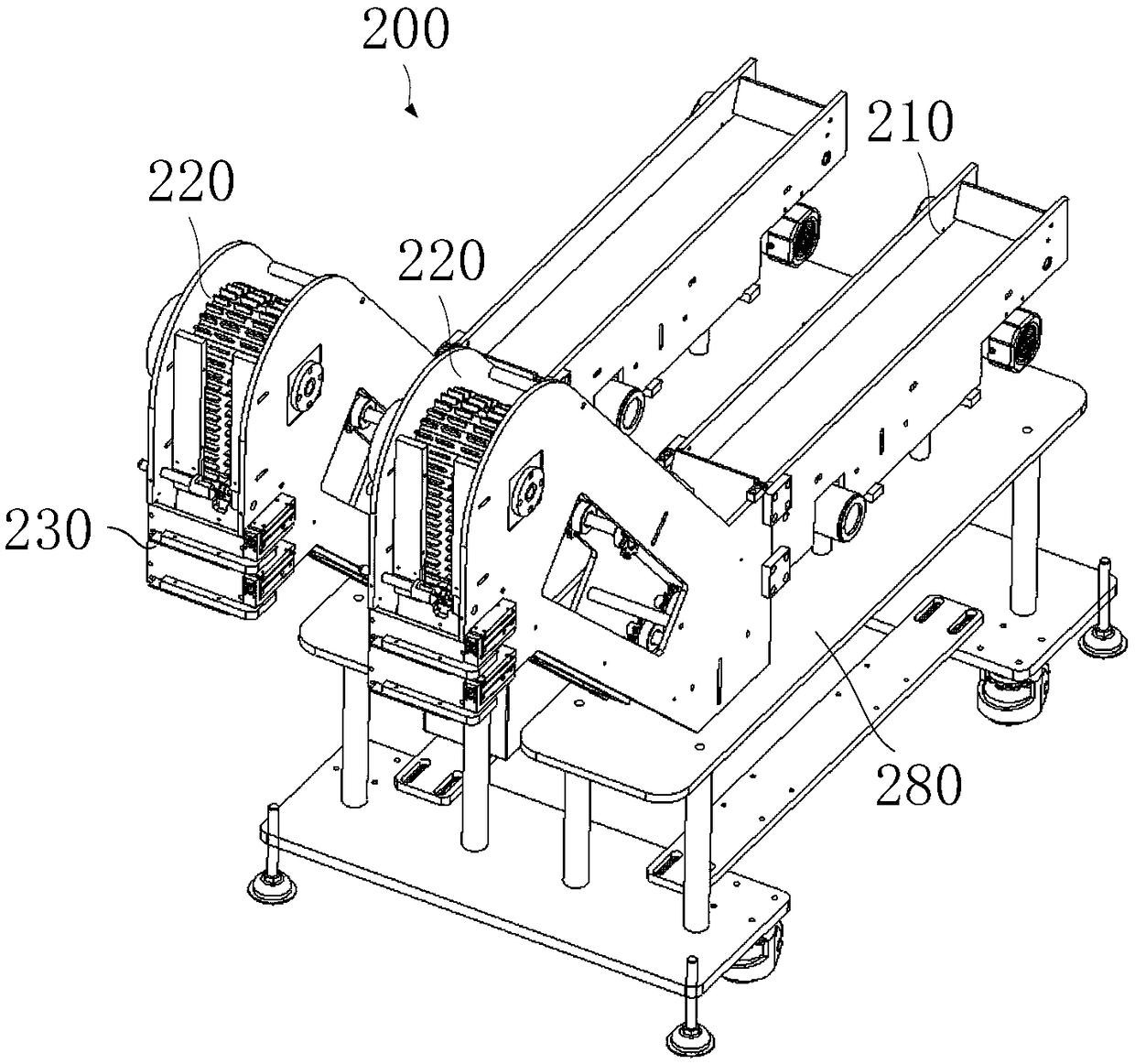

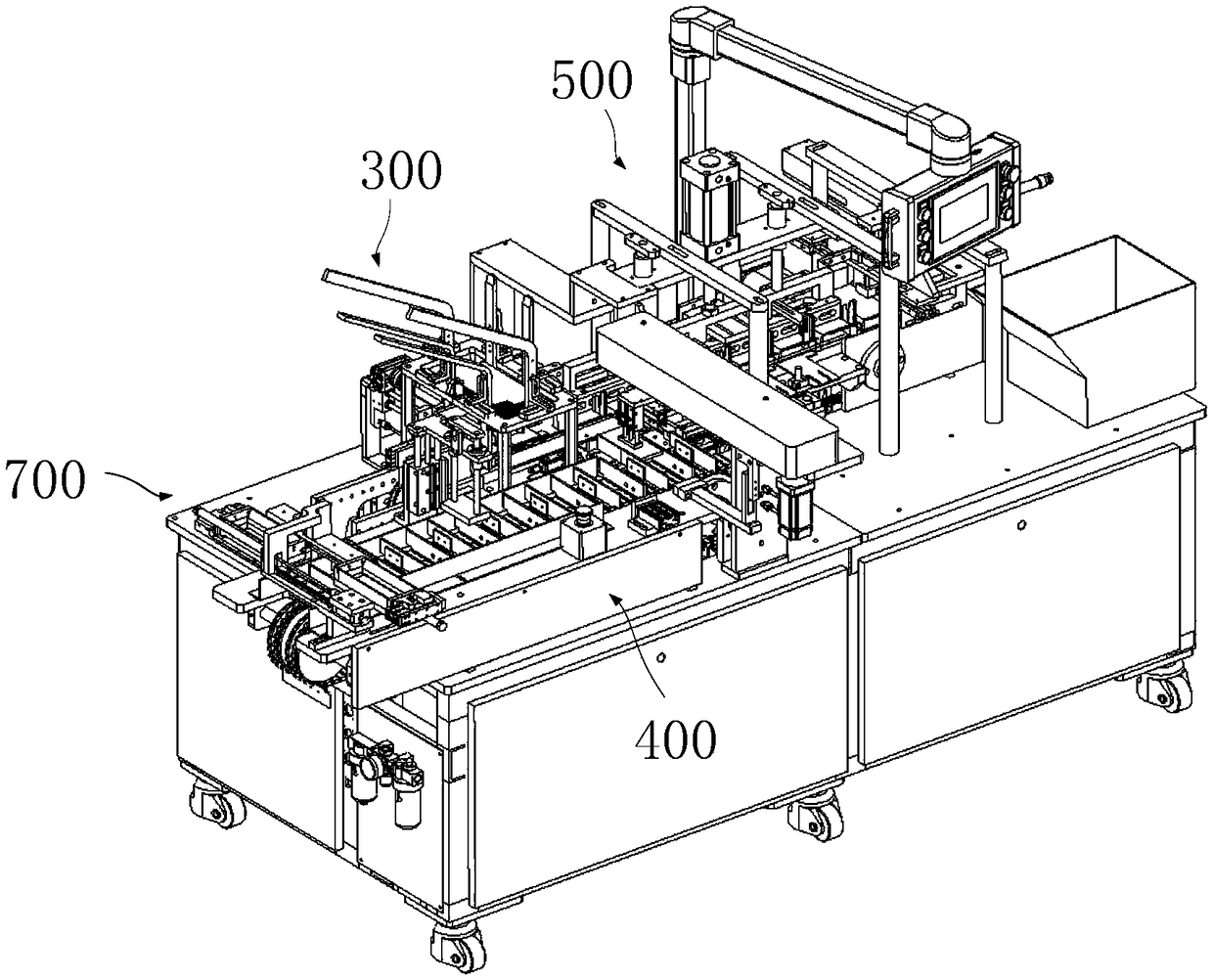

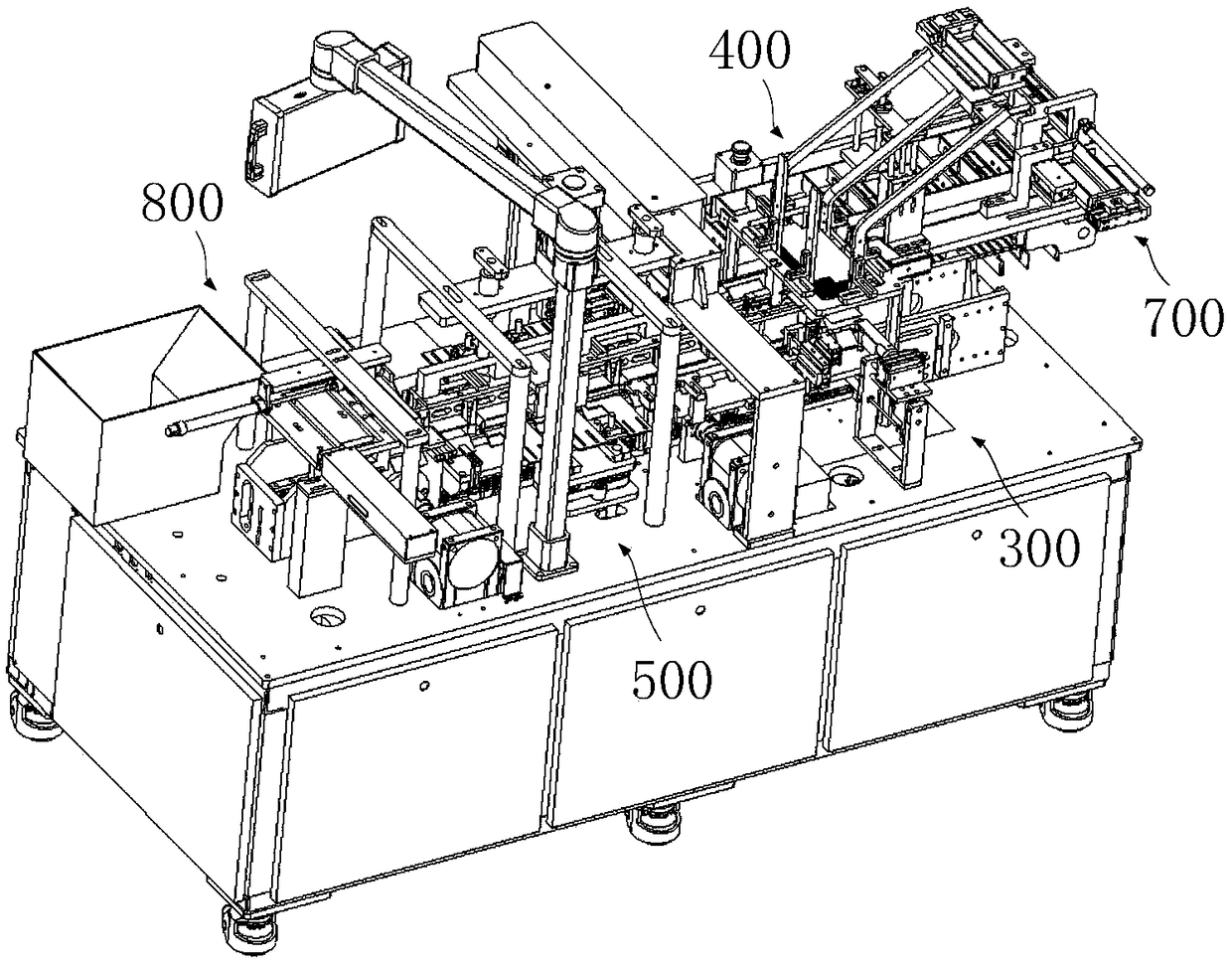

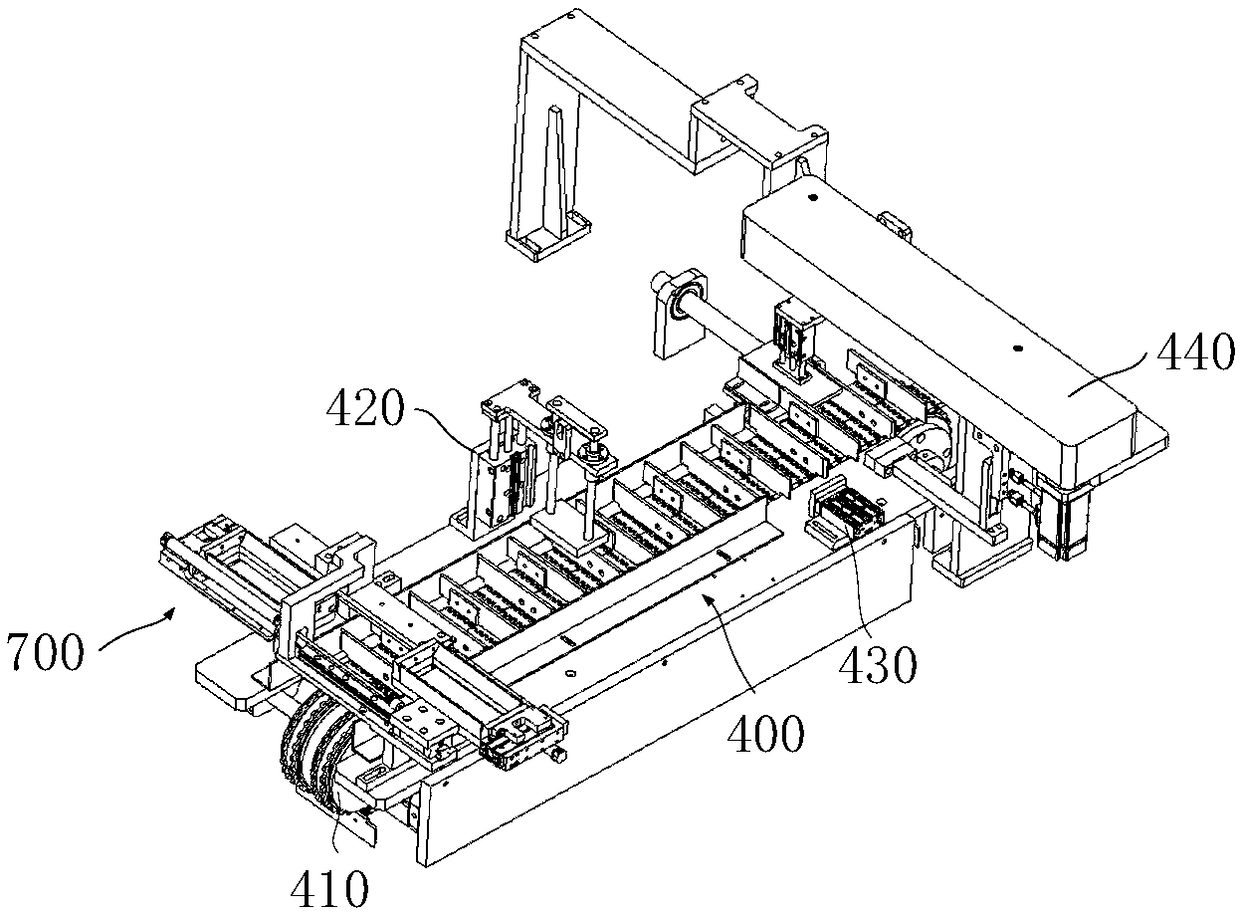

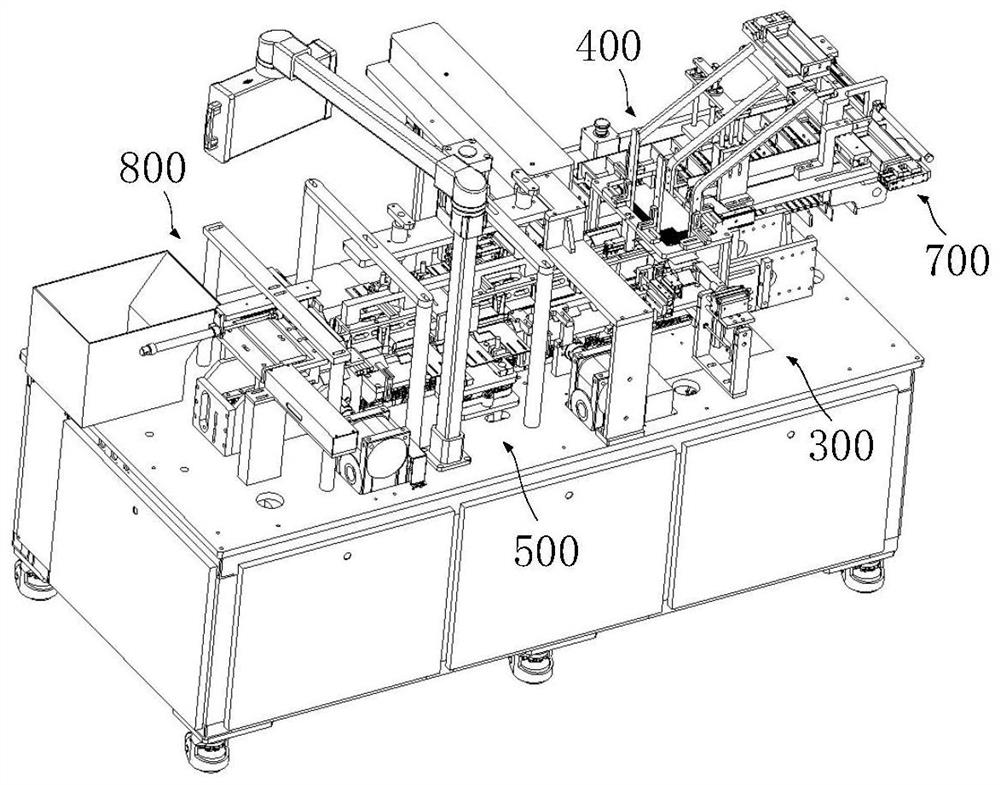

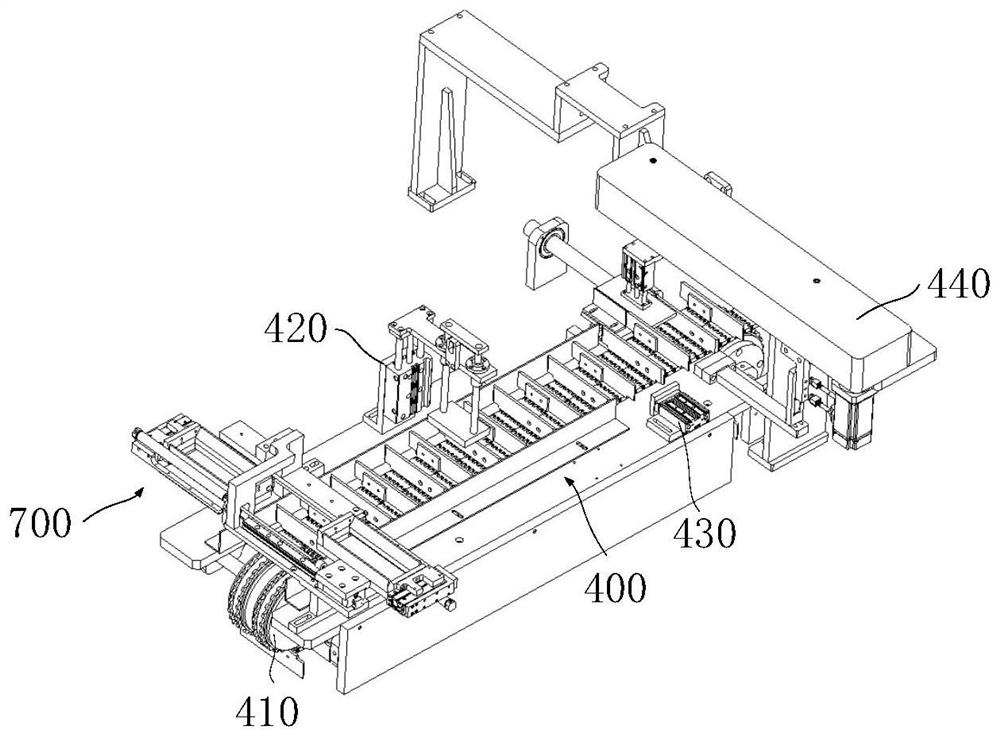

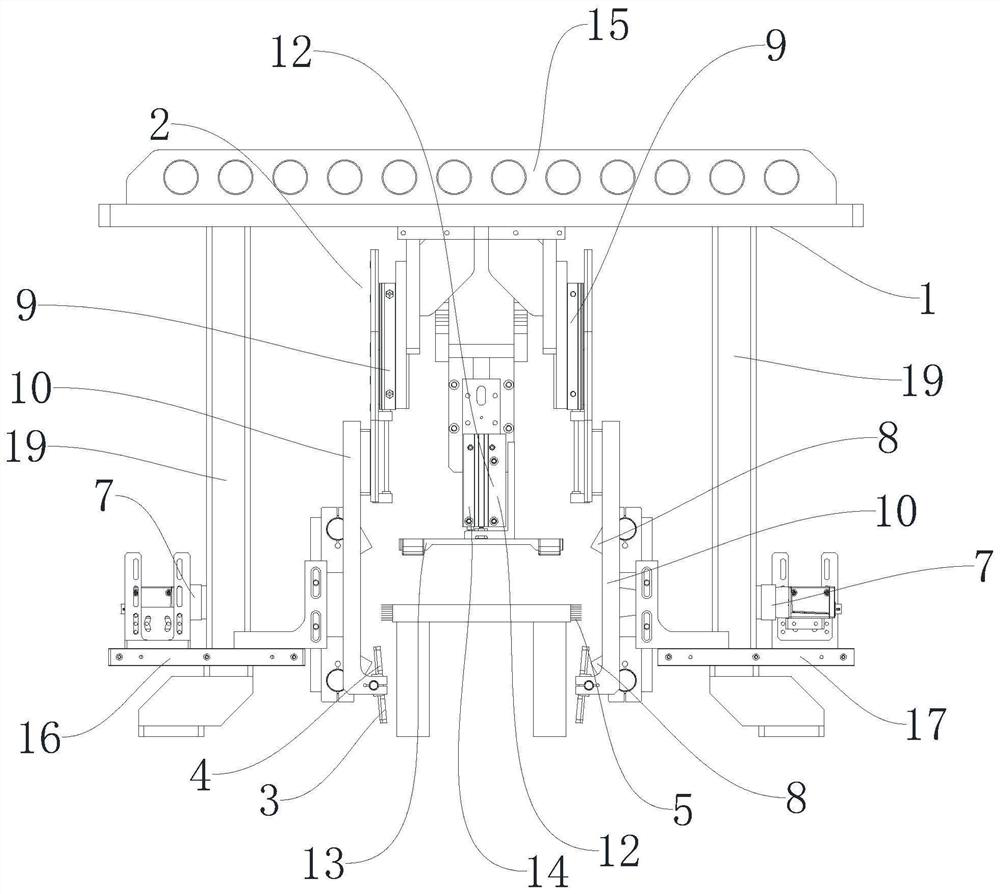

Packaging and stacking integrated device used for finished pen

InactiveCN109502086ASave box spaceHigh degree of automationRod-shaped articlesStacking articlesEngineeringIntegrated devices

The invention provides a packaging and stacking integrated device used for finished pens. The packaging and stacking integrated device comprises a packaging box opening mechanism, a material combiningconveying mechanism, a box closing device body, a stacking mechanism and a detecting device. The packaging box opening mechanism is used for expanding a first box body to form a second box body. Thematerial combining conveying mechanism is used for conveying the finished pens to the packaging position of a packaging box so that the finished pens can enter the second box body, and a third box body is formed. The box closing device body is used for collecting an opened side tongue and an insertion piece of the third box body into the box body so as to form a fourth box body. The detecting device is arranged at the rear portion of the box closing device body. The detecting device comprises a gravity detection assembly. The gravity detection assembly is used for detecting the weight of the fourth box body. By means of the packaging and stacking integrated device, automatic filling, packaging and stacking of the finished pens are achieved, the finished pen boxing space is saved, the finished pen boxing automation degree is improved, and the overall production efficiency is improved. The packaging and stacking integrated device is reasonable in design, ingenuous in conception, capableof facilitating automatic implementation and beneficial to application and popularization in the pen industry.

Owner:SUZHOU PAIFEITE AUTOMATION TECH CO LTD

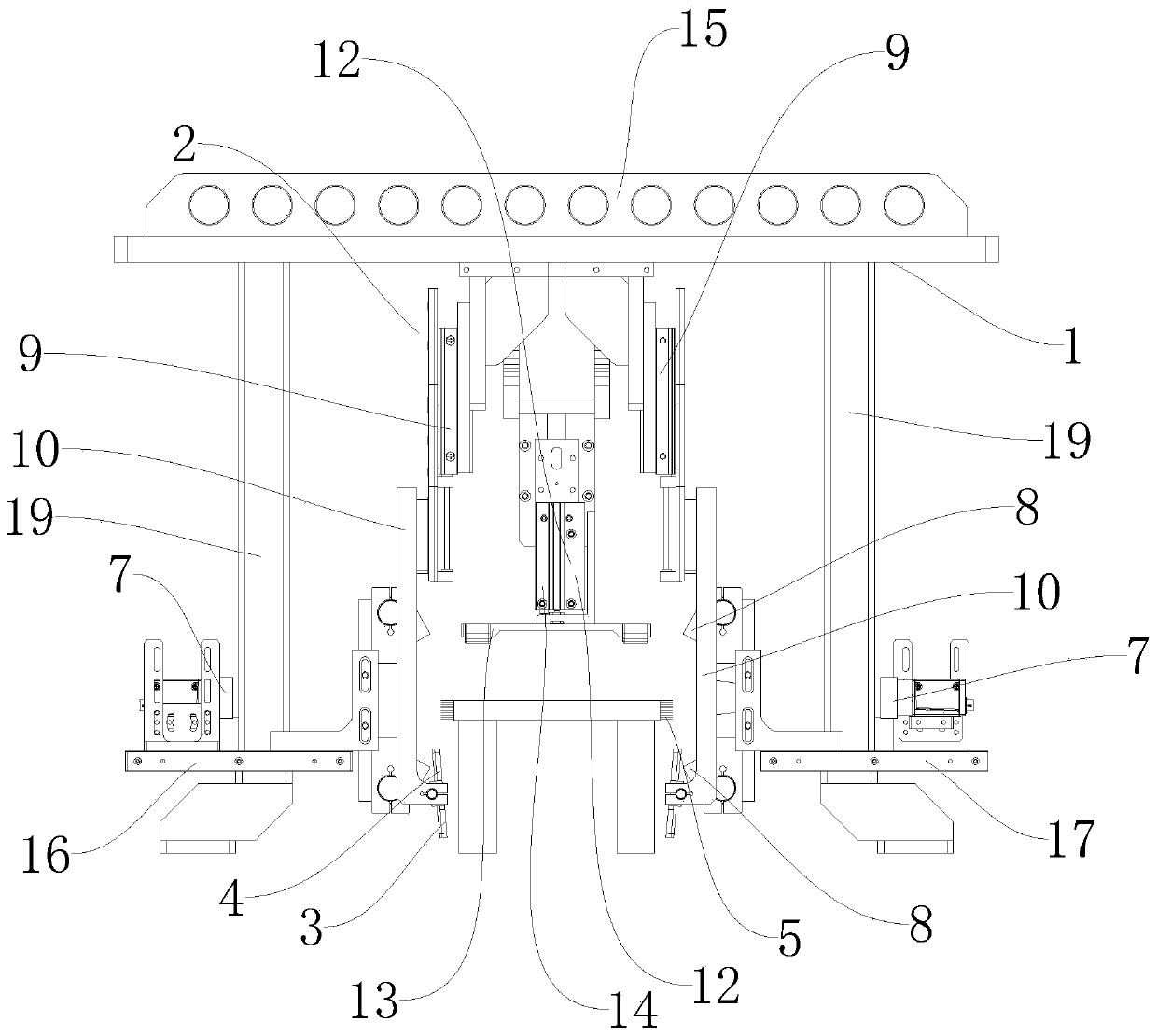

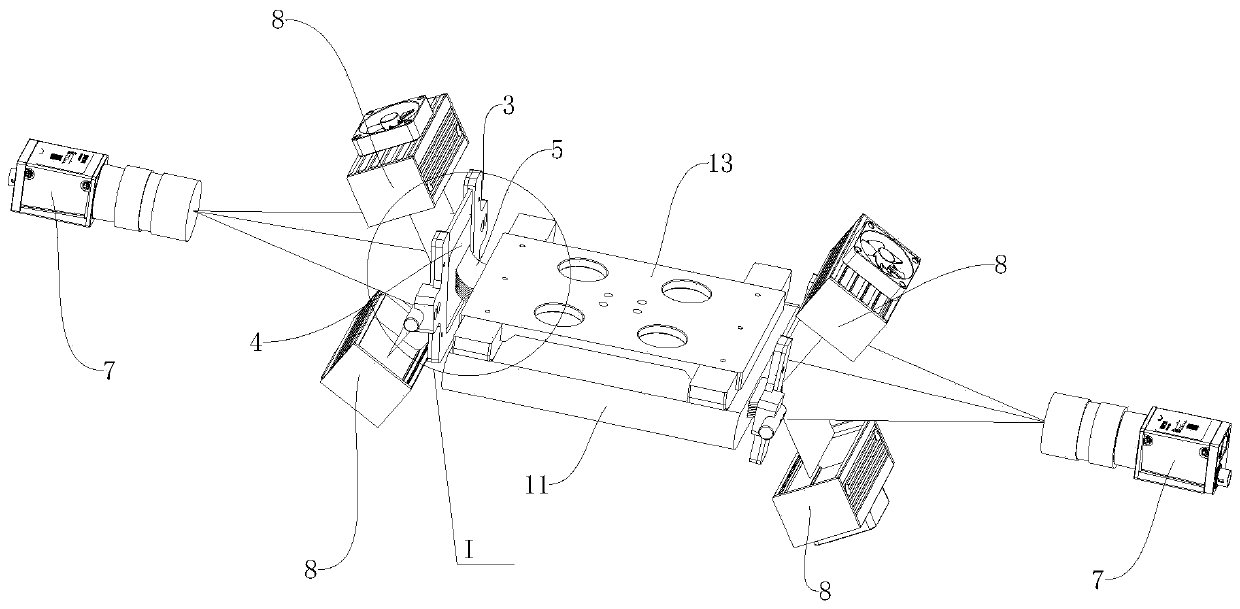

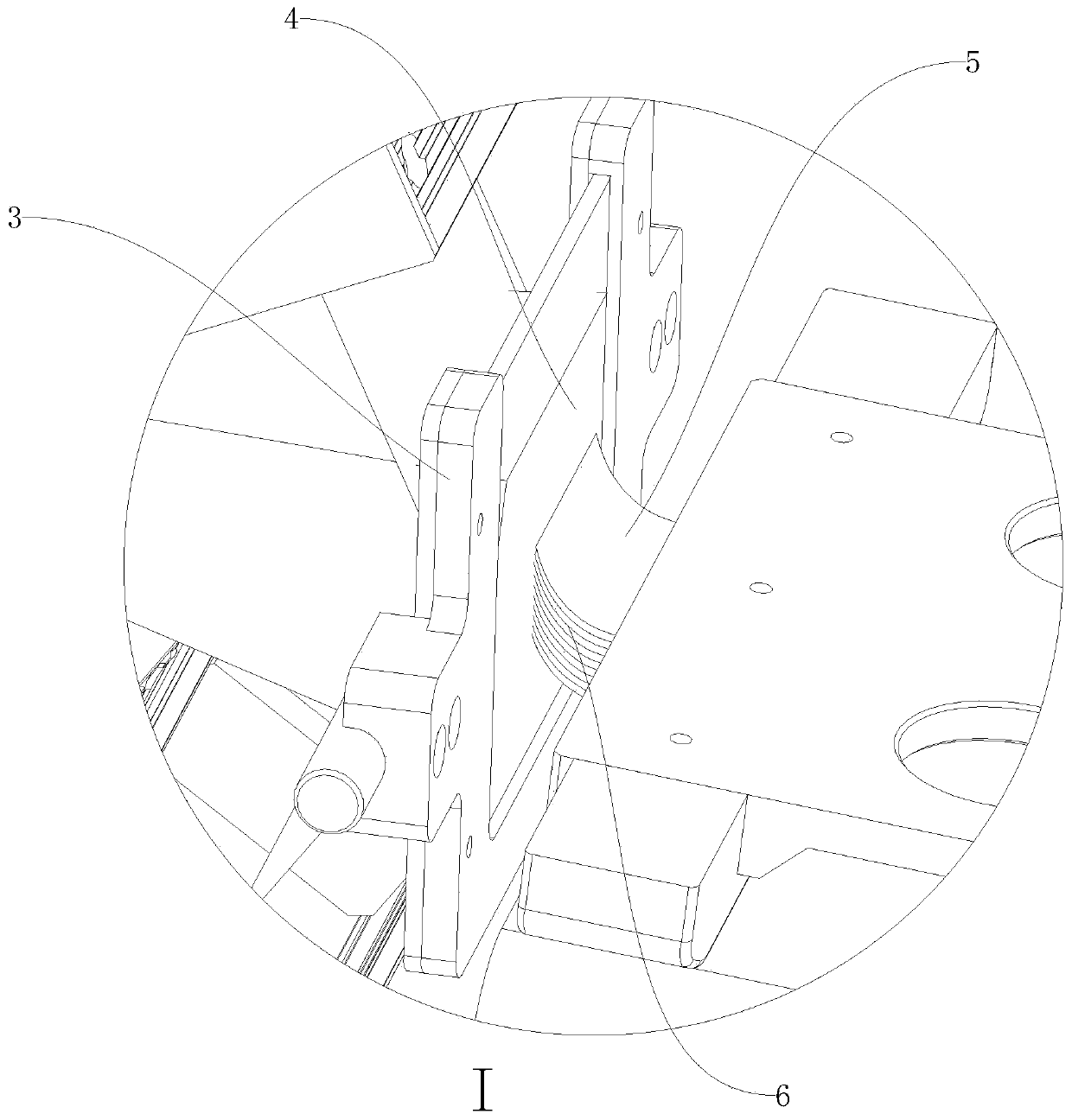

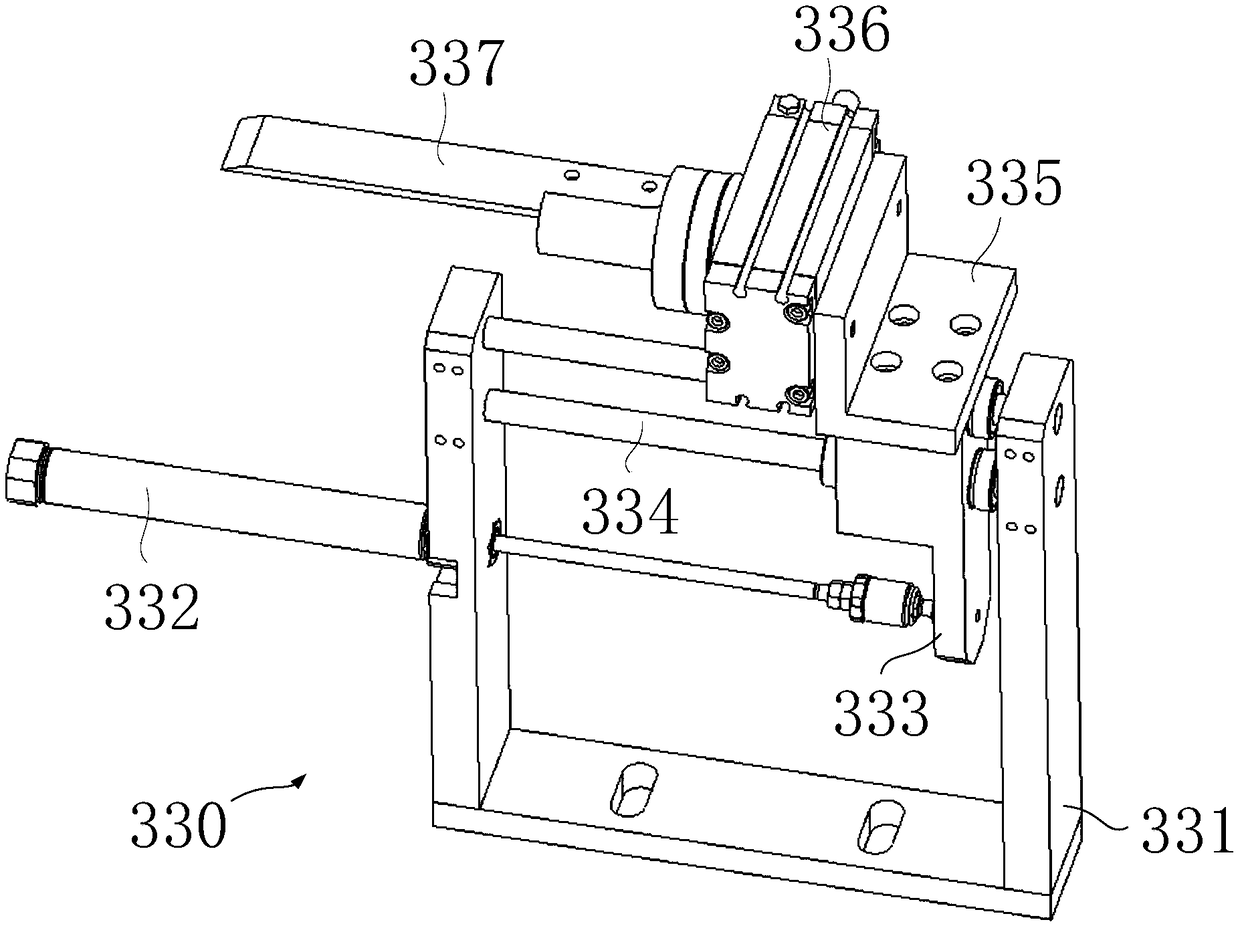

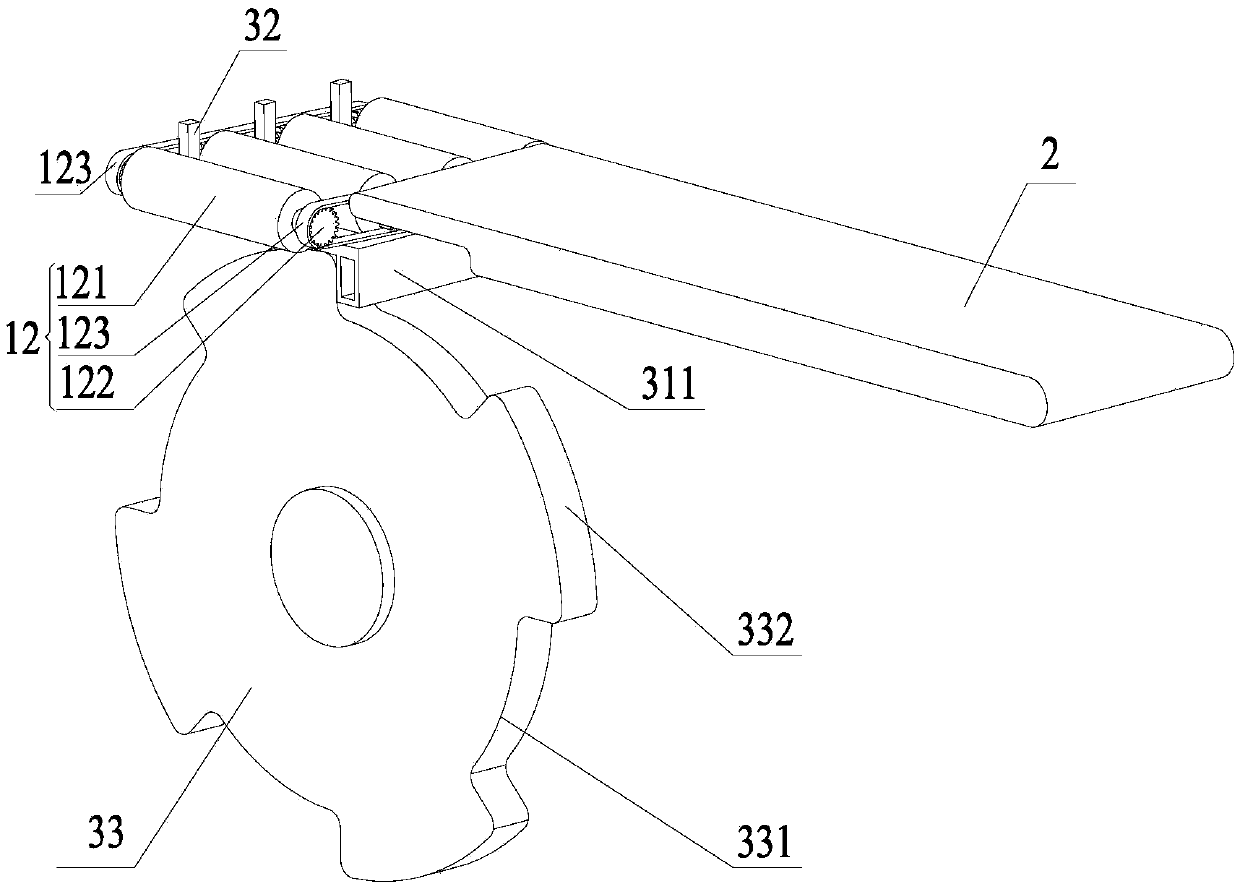

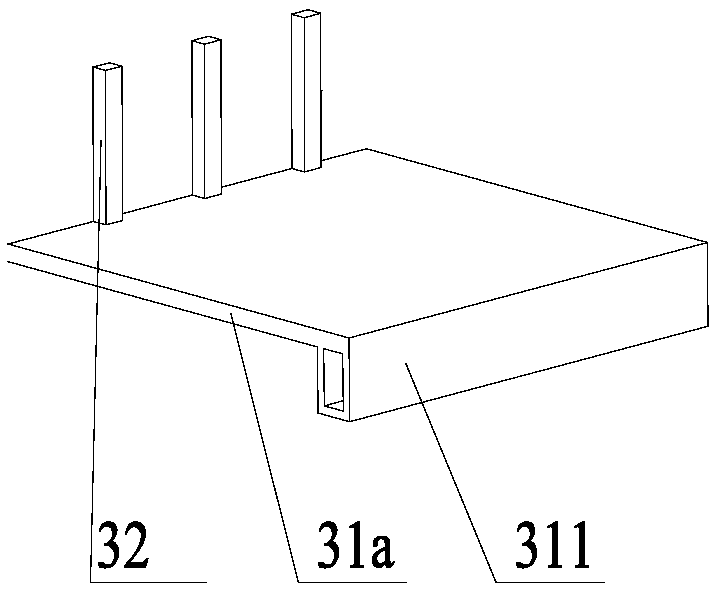

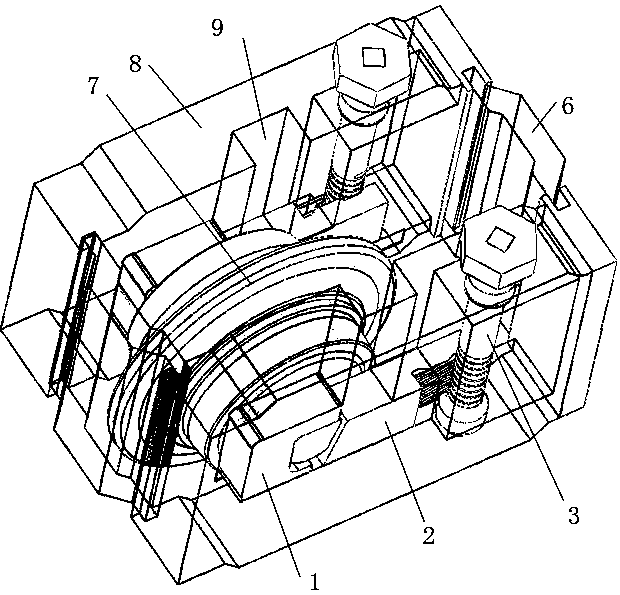

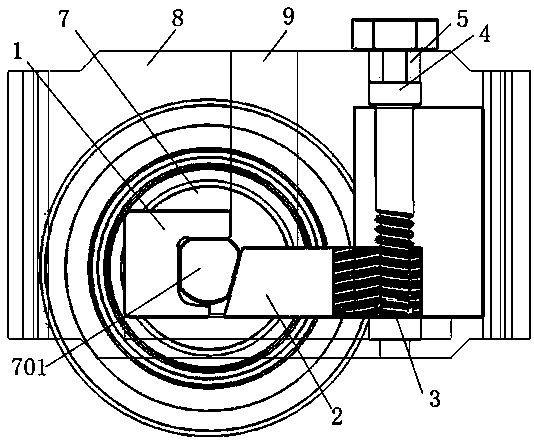

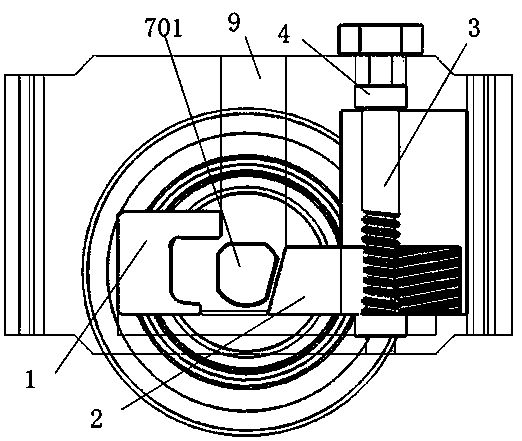

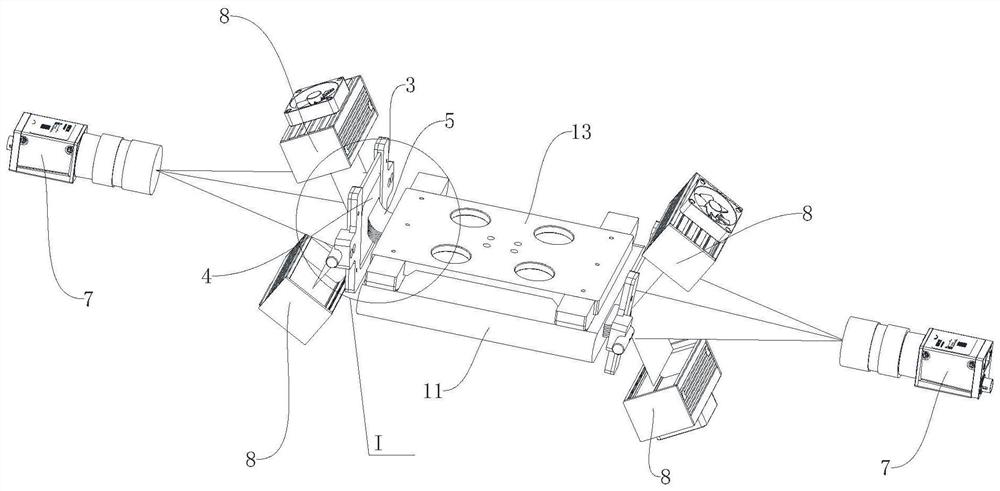

Detection device for lithium battery roll core tabs and lithium battery production line

ActiveCN109752386ARealize automated detectionWon't hurtFinal product manufactureSecondary cellsProduction lineUltimate tensile strength

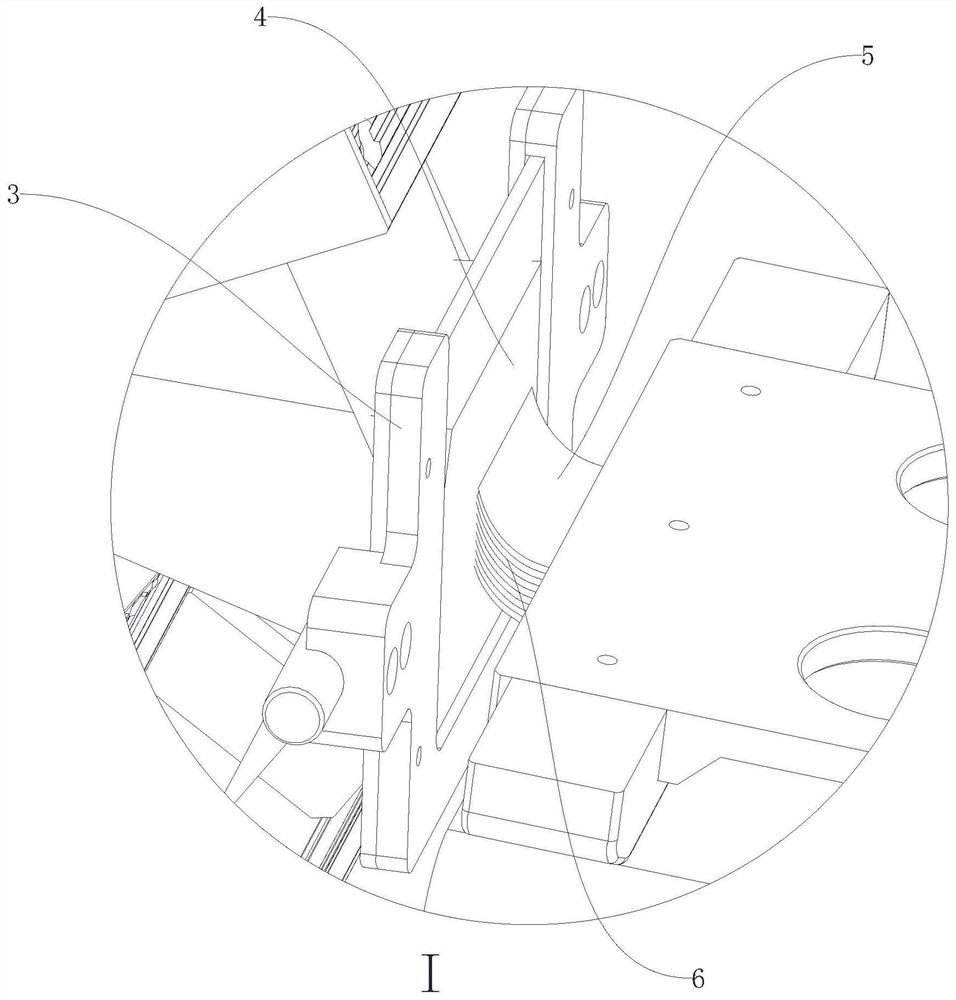

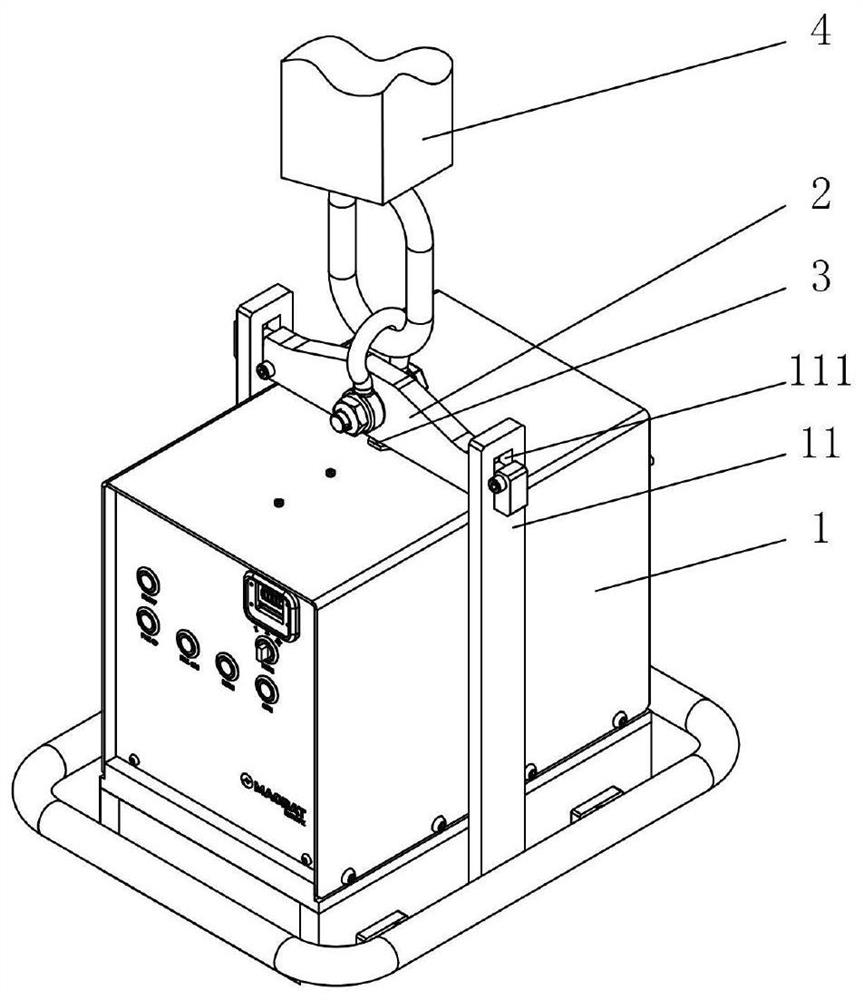

The invention relates to the field of lithium battery production detection, and discloses a detection device for lithium battery roll core tabs and a lithium battery production line. A rack (1) is provided with an adjusting mechanism (2) for bending horizontal tabs (5); the adjusting mechanism (2) comprises a bending plate (3) used for bending the tabs (5); during detection, the tabs (5) abut against the bending plate (3) to be bent and then a gap between the outer ends of sheets of the adjacent tabs (5) is expanded; the bending plate (3) comprises a transparent plate (4); and during the detection, the tabs (5) abut against the transparent plate (4). The tabs are bent to increase the distance between the end parts, and then a visual system can be used on the detected tabs, so that the working efficiency of the detection is greatly improved, the labor is reduced, the labor intensity is reduced, and automatic implementation is facilitated.

Owner:浙江双元科技股份有限公司

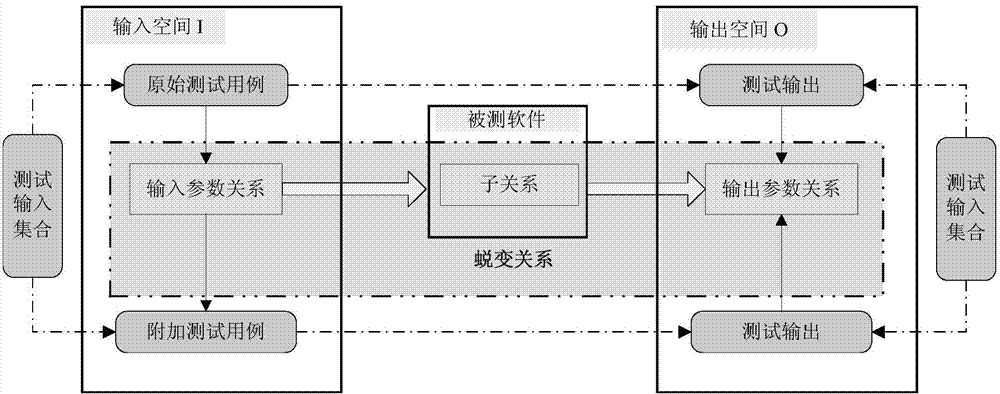

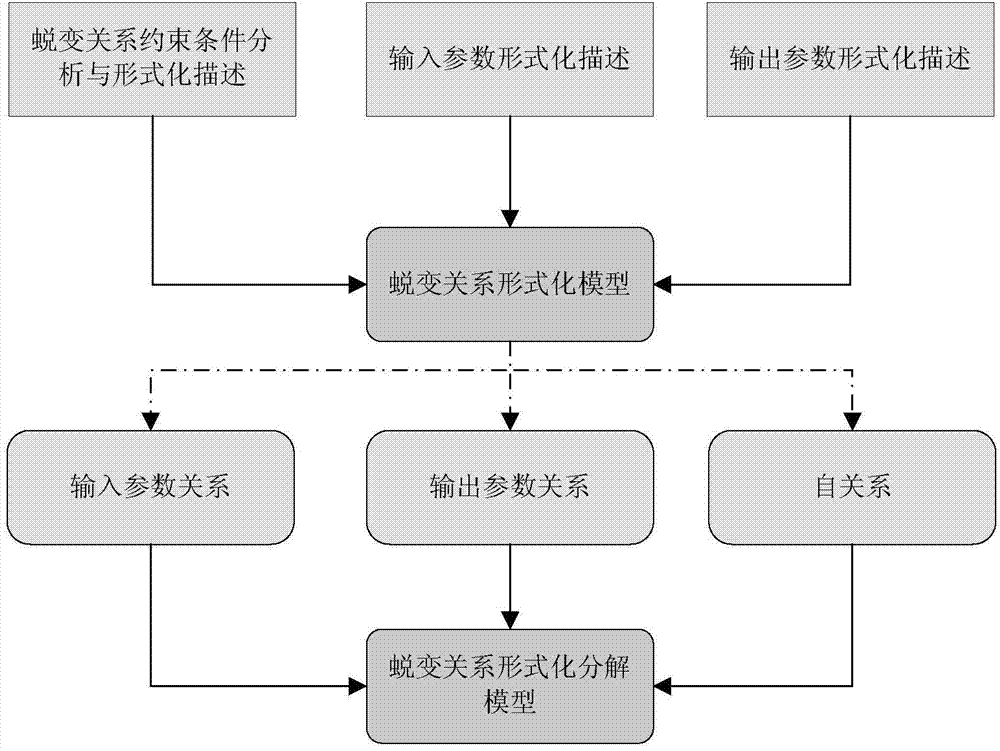

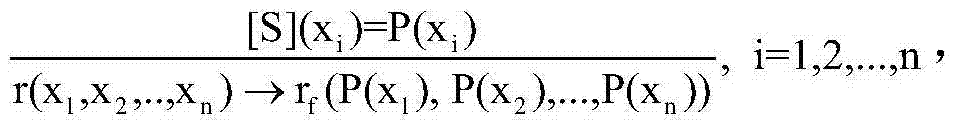

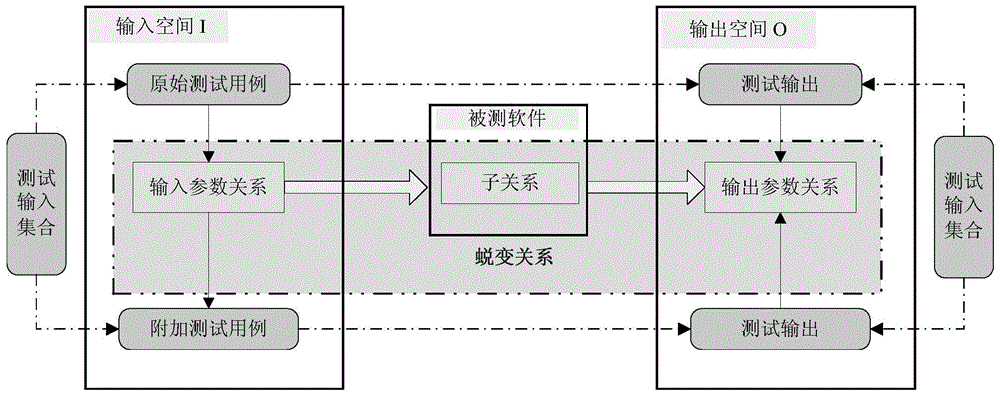

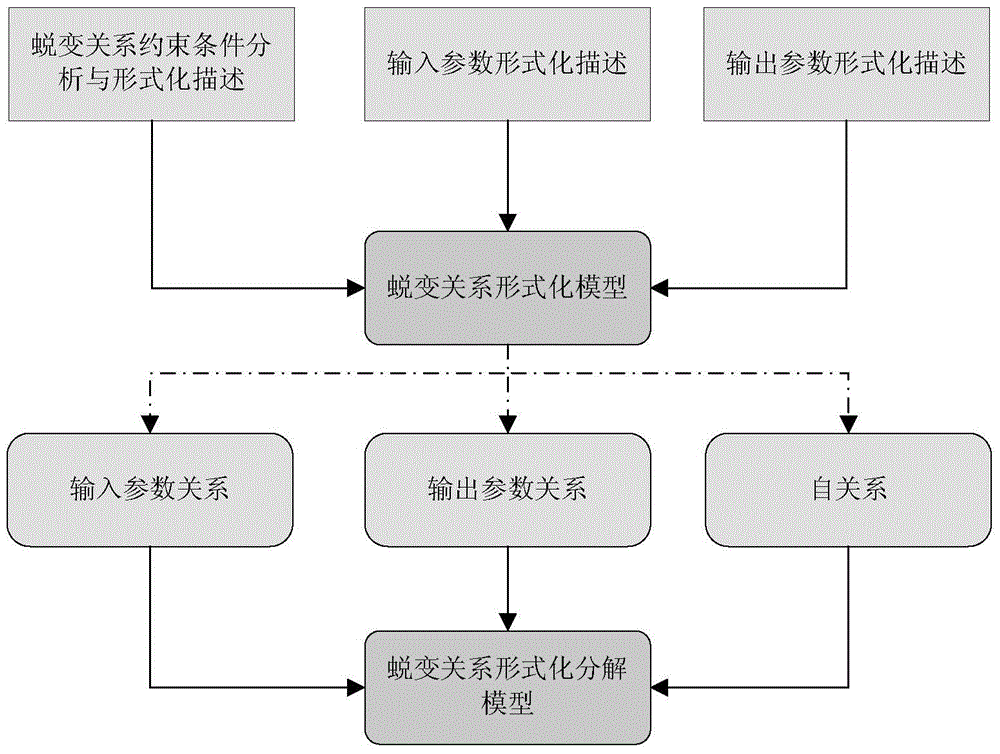

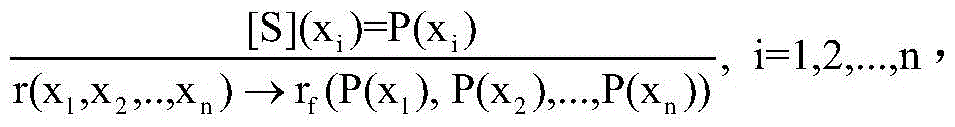

Formal description and decomposition method for metamorphic relation

ActiveCN103713997AFacilitates automated implementationPrecise formal descriptionSoftware testing/debuggingApplicability domainDecomposition

The invention discloses a formal description and decomposition method for a metamorphic relation. The method includes the following steps: (1) according to targeted tested software, extracting and designing the metamorphic relation that the software mush satisfy to create the metamorphic relation; (2) performing formal modeling on the obtained metamorphic relation on the basis of symbolic logic, determining constraint conditions under which the metamorphic relation is established, performing formal description, then describing input parameters and output parameters of the metamorphic relation on the basis of the symbolic logic, and establishing a formal description model of the metamorphic relation; (3) on the basis of the formal model, respectively extracting subrelations forming the metamorphic relation and a set description form of a metamorphic relation composition model, and establishing a metamorphic relation decomposition model. The method is simple and clear, description capacity and application range of the formal model are guaranteed through symbolic logic description, the accurate, standard and effective method is provided for description of the metamorphic relation, and the method is more conducive to automated implementation of subsequent metamorphic testing.

Owner:PLA UNIV OF SCI & TECH

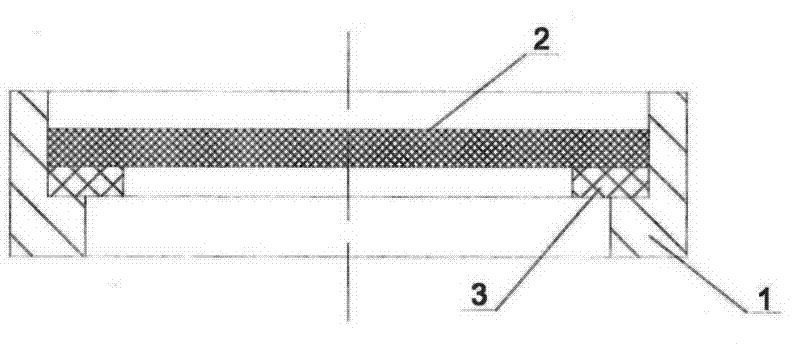

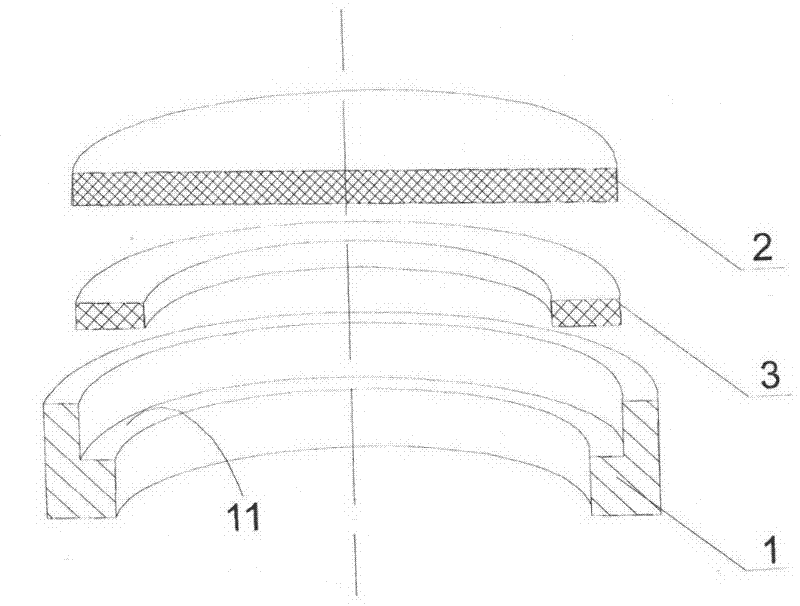

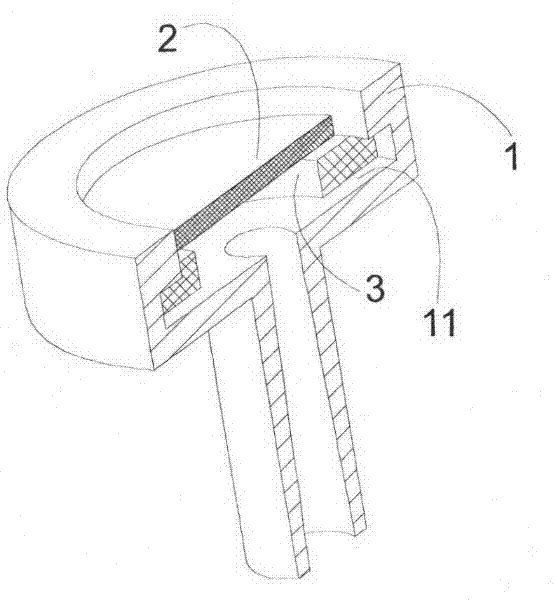

Safety filter based on coupling principle and manufacturing method of safety filter

InactiveCN102500015AMeet the safety requirementsMeet safety requirementsFiltering accessoriesMedical equipmentCoupling

The invention relates to the technical field of medical equipment, in particular to a safety filter based on the coupling principle and a manufacturing method of the safety filter. According to the safety filter, materials are used as a coupling layer between two different materials by utilizing the characteristic that the similarity of the materials exists between the two materials with different ingredients skillfully, so that a filter membrane which is difficult to bond is tightly bonded with a filter membrane support or the bonding strength of the filter membrane is enhanced by the coupling layer, and the filter is safe. In addition, on the basis of the safety filter, the invention further provides a manufacturing method.

Owner:凌海燕

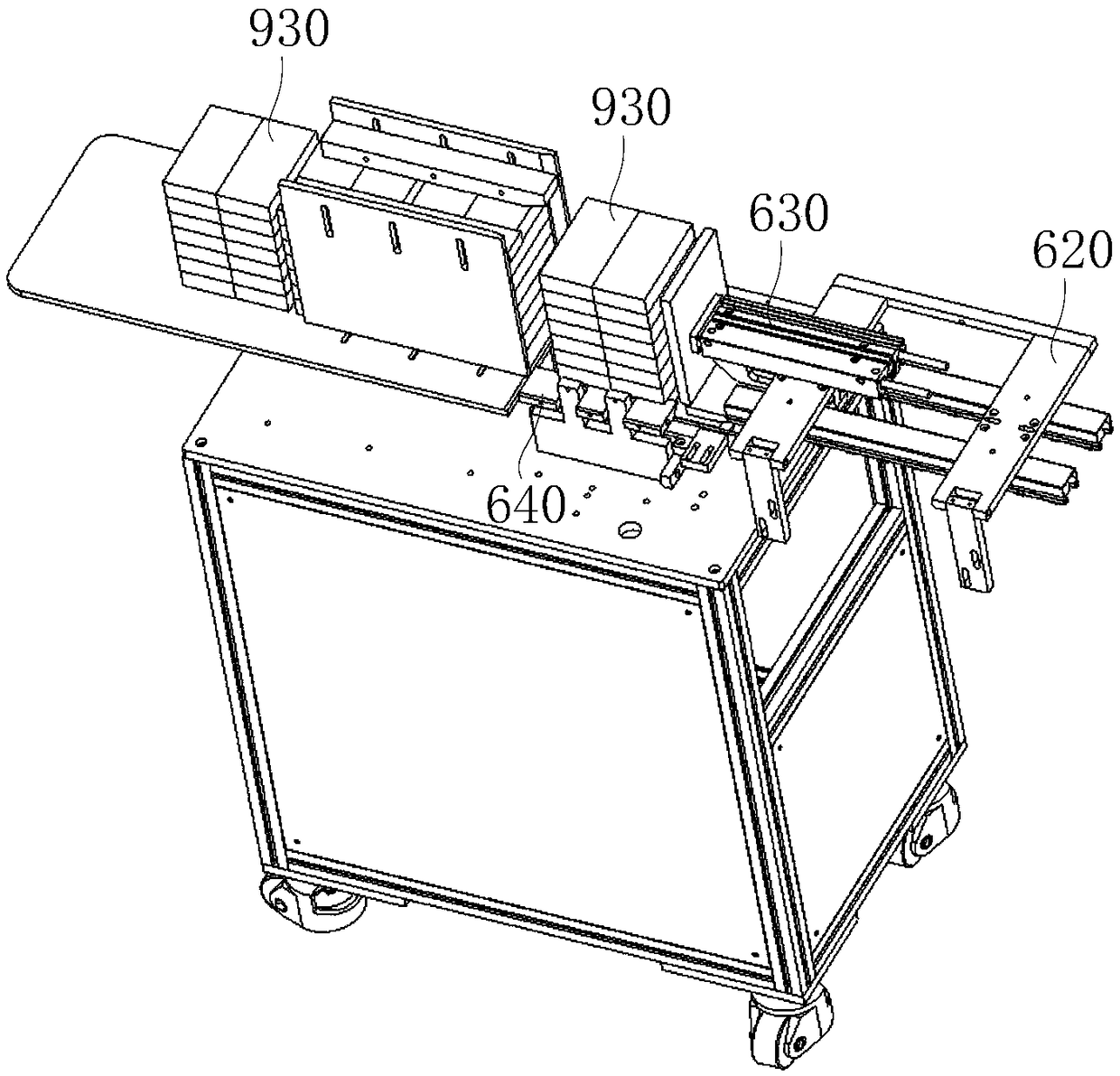

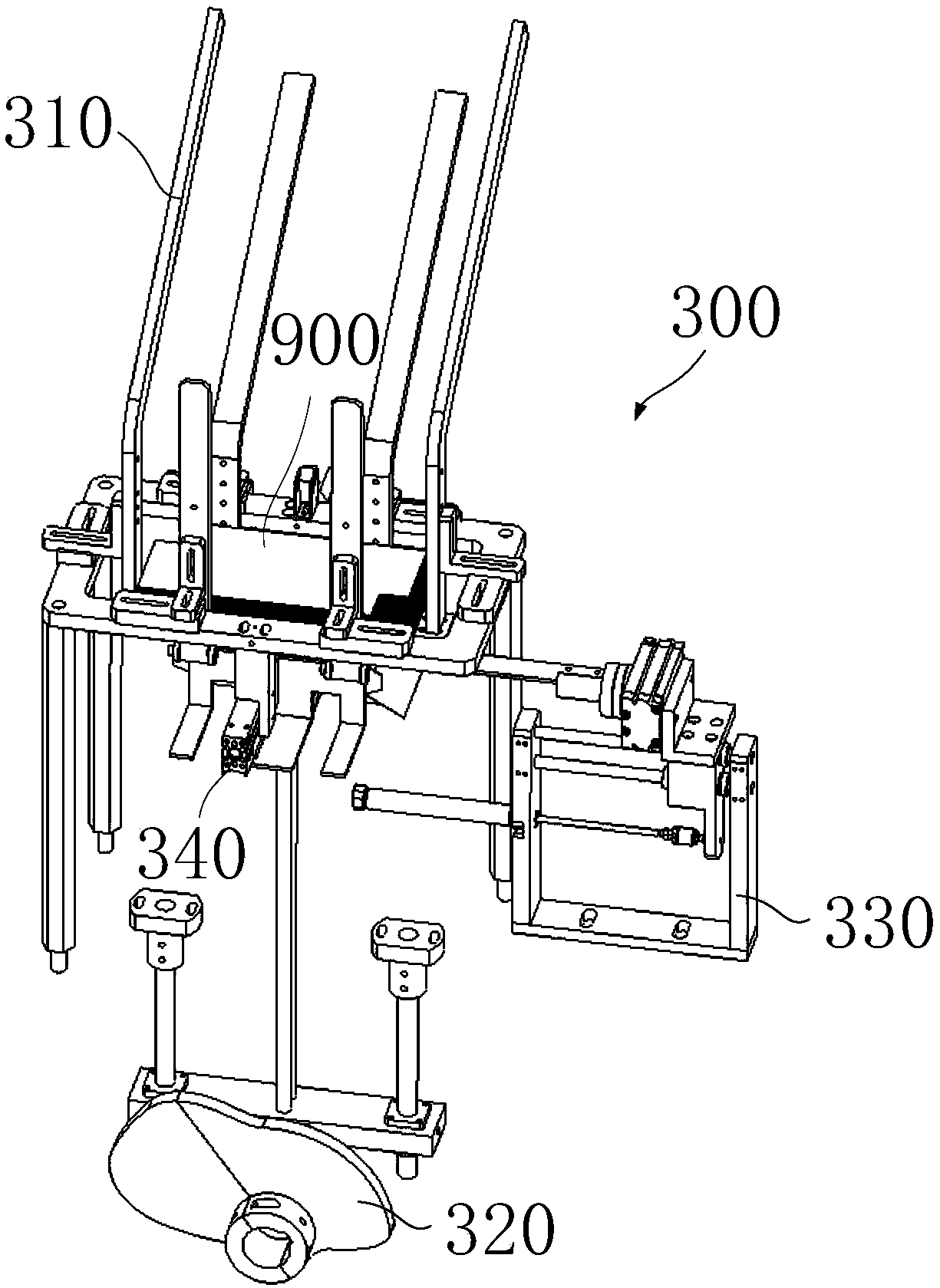

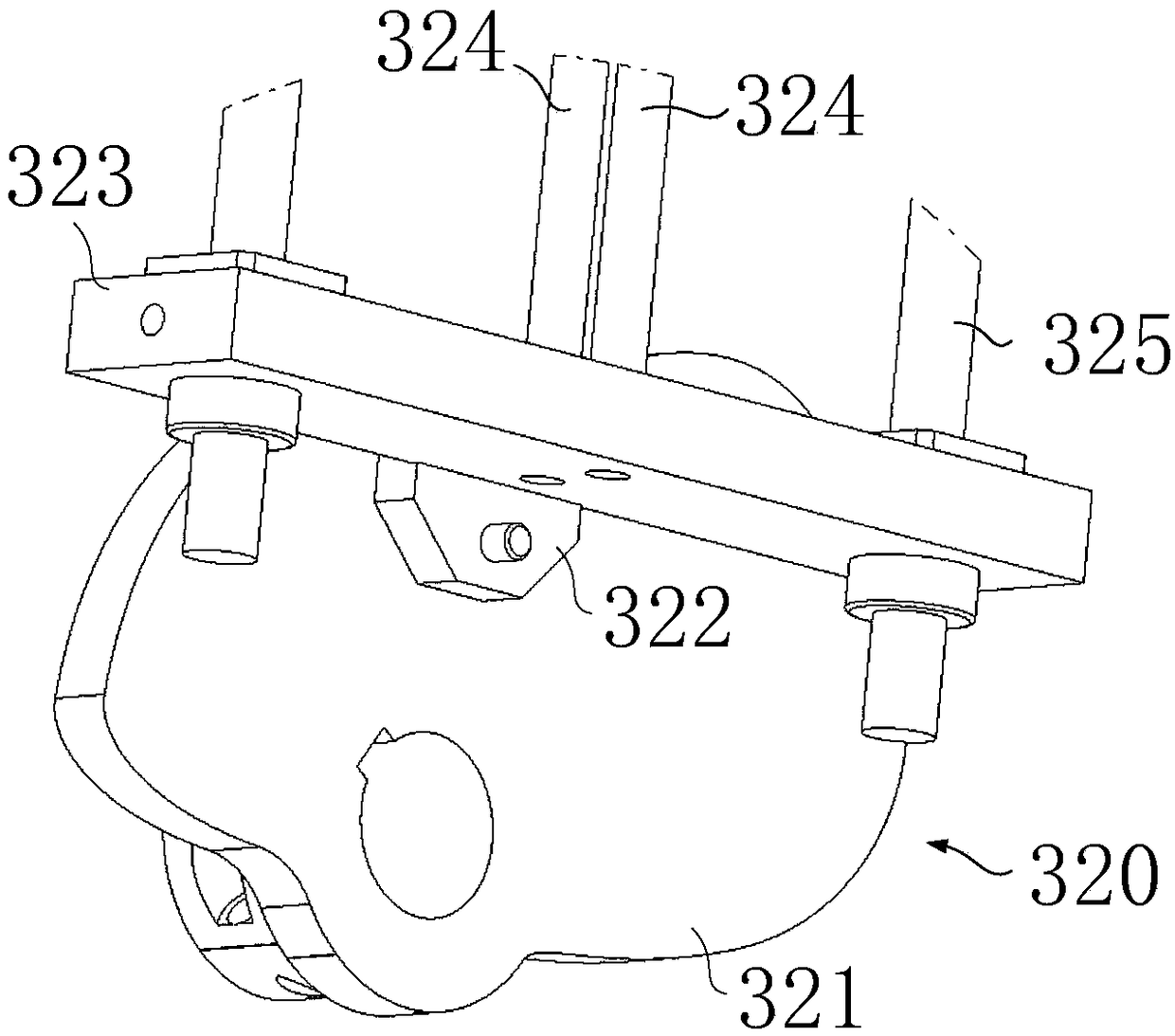

Finished pen packaging box stacking device

InactiveCN109502354AHigh degree of automationImprove production pass rateStacking articlesEngineeringAutomation

The invention provides a finished pen packaging box stacking device which comprises a stacking mechanism and a detecting device. The detecting device is arranged at the front end of the stacking mechanism and comprises a gravity detection assembly and an inferior-quality product ejection assembly. The gravity detection assembly is used for detecting the weight of fourth box bodies. The inferior-quality product ejection assembly is used for ejecting the fourth box bodies with unqualified weight. The stacking mechanism comprises a stacking conveying assembly, a stacking material pushing assemblyand a stacking material ejection assembly. The stacking conveying assembly is used for conveying the fourth box bodies with qualified weight to the position of the stacking material ejection assembly. The stacking material ejection assembly is used for ejecting the fourth box bodies to the position in front of the stacking material push assembly from the lower portion. The stacking material pushassembly is used for pushing out the stacked fourth box bodies. By means of the finished pen packaging box stacking device, a gravity detection manner is adopted for detecting finished pen packages, the overall production qualification rate is increased, meanwhile, the bottom-to-top stacking mechanism is adopted, the automation degree of finished pen boxing is improved, and the overall productionefficiency is improved. By means of the finished pen packaging box stacking device, automatic implementation is facilitated, and application and popularization in the pen industry are facilitated.

Owner:SUZHOU PAIFEITE AUTOMATION TECH CO LTD

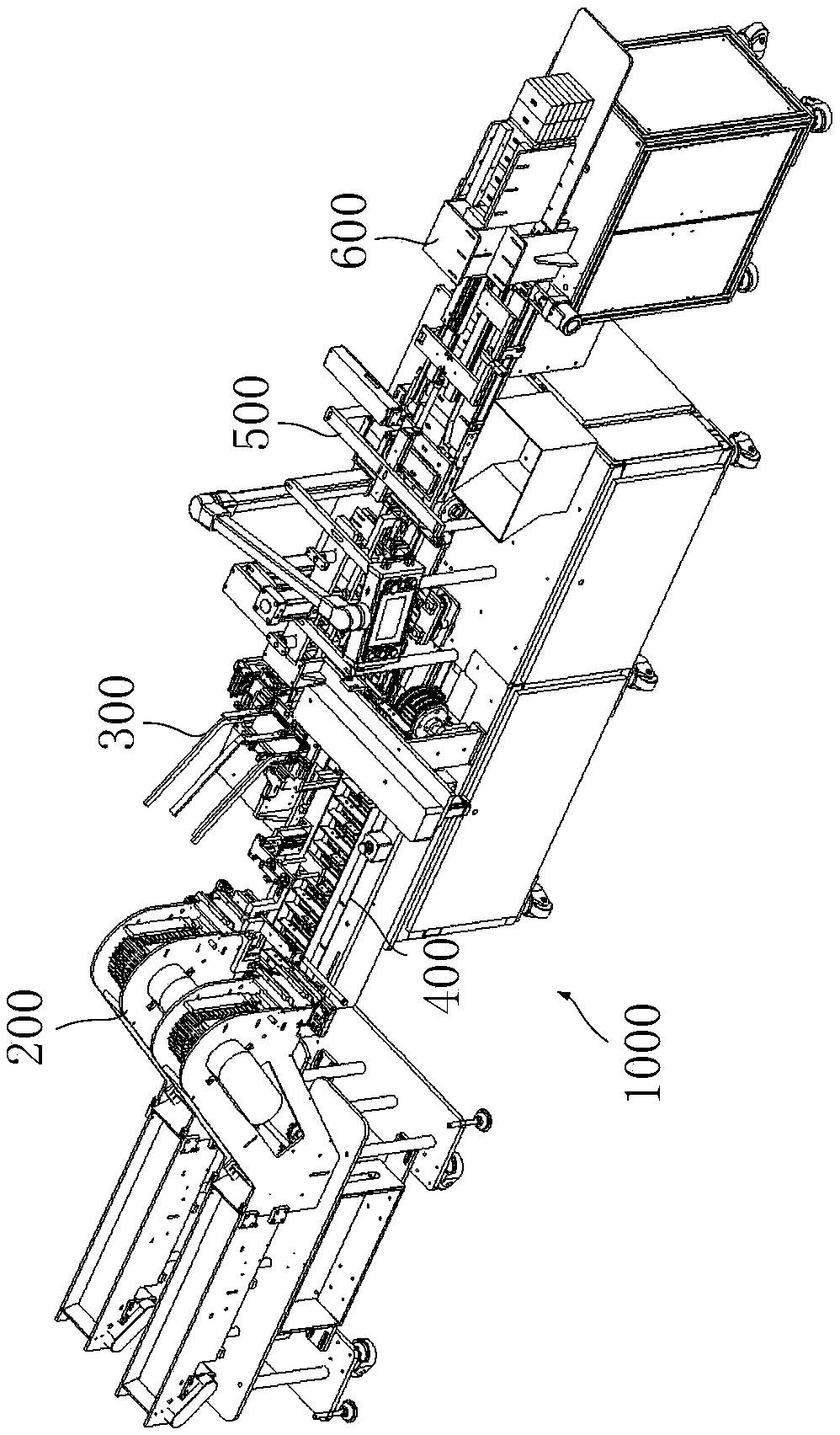

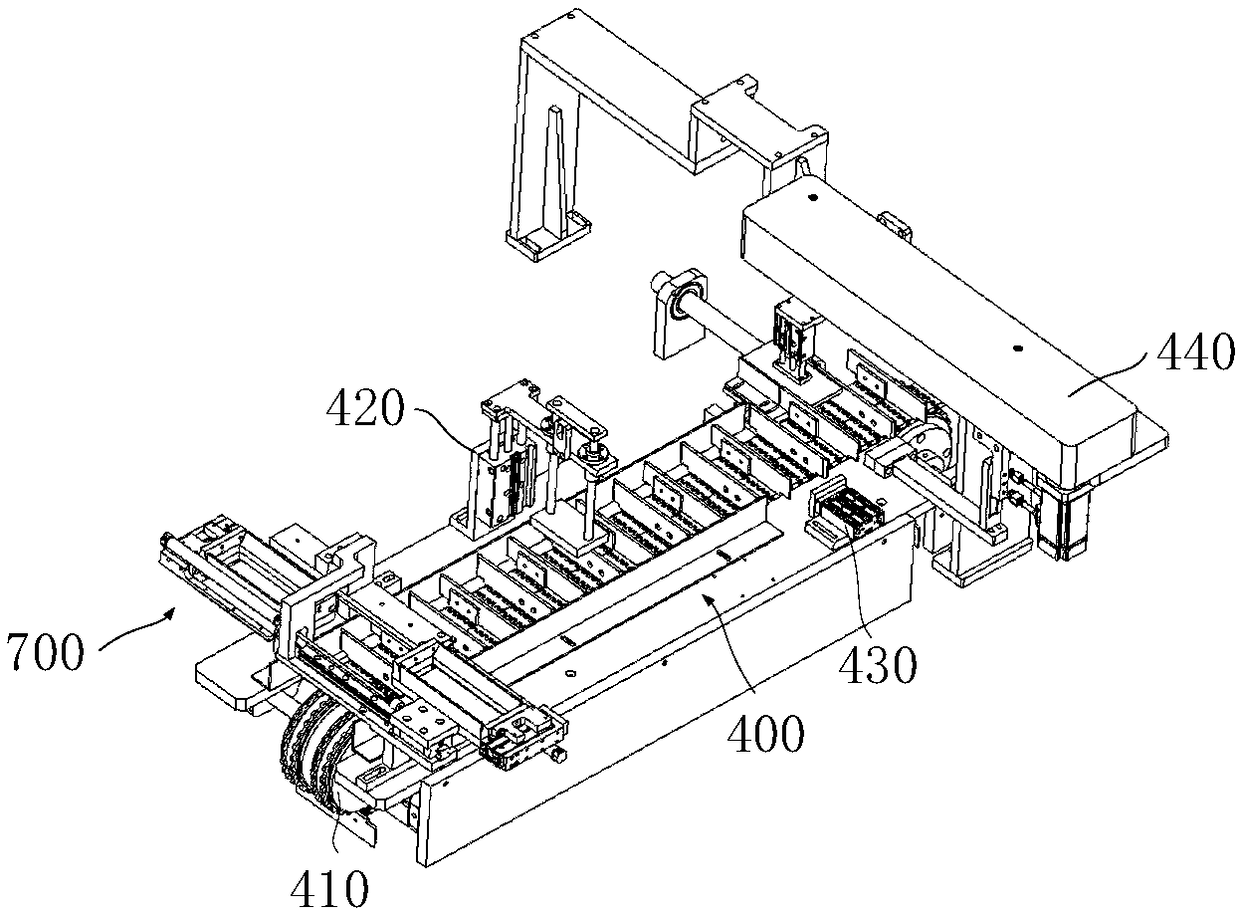

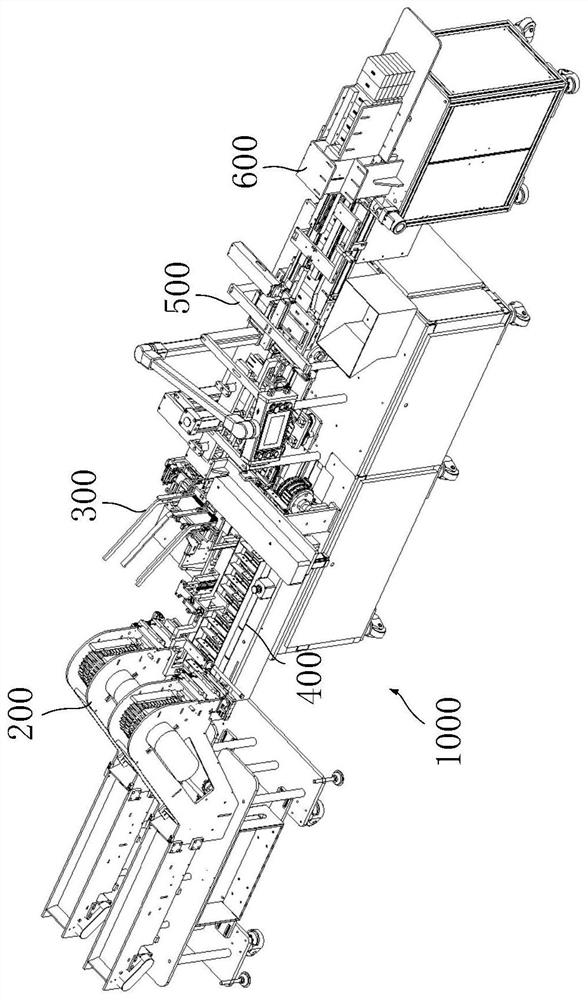

Automatic packaging production line for finished pens

ActiveCN109502087ASave spaceHigh degree of automationRod-shaped articlesStacking articlesManufacturing lineAutomation

The invention provides an automatic packaging production line for finished pens. The automatic packaging production line comprises a packaging device body. The packaging device body comprises a feeding body, a packaging box opening mechanism, a material combining conveying mechanism, a box closing device body, a stacking mechanism, a material combining mechanism and a detecting device. By means ofthe automatic packaging production line for the finished pens, automatic feeding, filling, packaging and stacking of the finished pens are achieved, the blank of an automatic production line of the pen industry is filled up, meanwhile, the finished pen boxing space is saved, the finished pen boxing automation degree is improved, and the overall production efficiency is improved. The automatic packaging production line for the finished pens is reasonable in design, ingenious in concept and capable of facilitating automatic implementation and facilitating pen industry application and popularization.

Owner:SUZHOU PAIFEITE AUTOMATION TECH CO LTD

Packaging mechanism for packaging finished pen products

InactiveCN109502099AOptimize the automation processHigh degree of automationRod-shaped articlesEngineeringExtrusion

The invention provides a packaging mechanism for packaging finished pen products. The packaging mechanism comprises a packaging box opening mechanism which comprises a guiding frame, a box sucking assembly, a first extrusion assembly and a second extrusion assembly; a plurality of flat first box bodies are placed in the guiding frame; the first extrusion assembly and the second extrusion assemblyare arranged below the guiding frame; and the box sucking assembly is used for sucking the first box bodies out of the guiding frame, at the moment, the first extrusion assembly and the second extrusion assembly move towards the first box bodies and extrude the two sides of the first box bodies to enable the first box bodies to be propped open. The packaging box opening mechanism is adopted, the pen box packaging automatic process is optimized, the automation degree of finished pen product boxing is increased, and the overall production efficiency is improved; and the packaging mechanism is reasonable in design and ingenious in conception, automatic implementation is convenient, and the packaging mechanism is advantageously applied and popularized to the pen industry.

Owner:SUZHOU PAIFEITE AUTOMATION TECH CO LTD

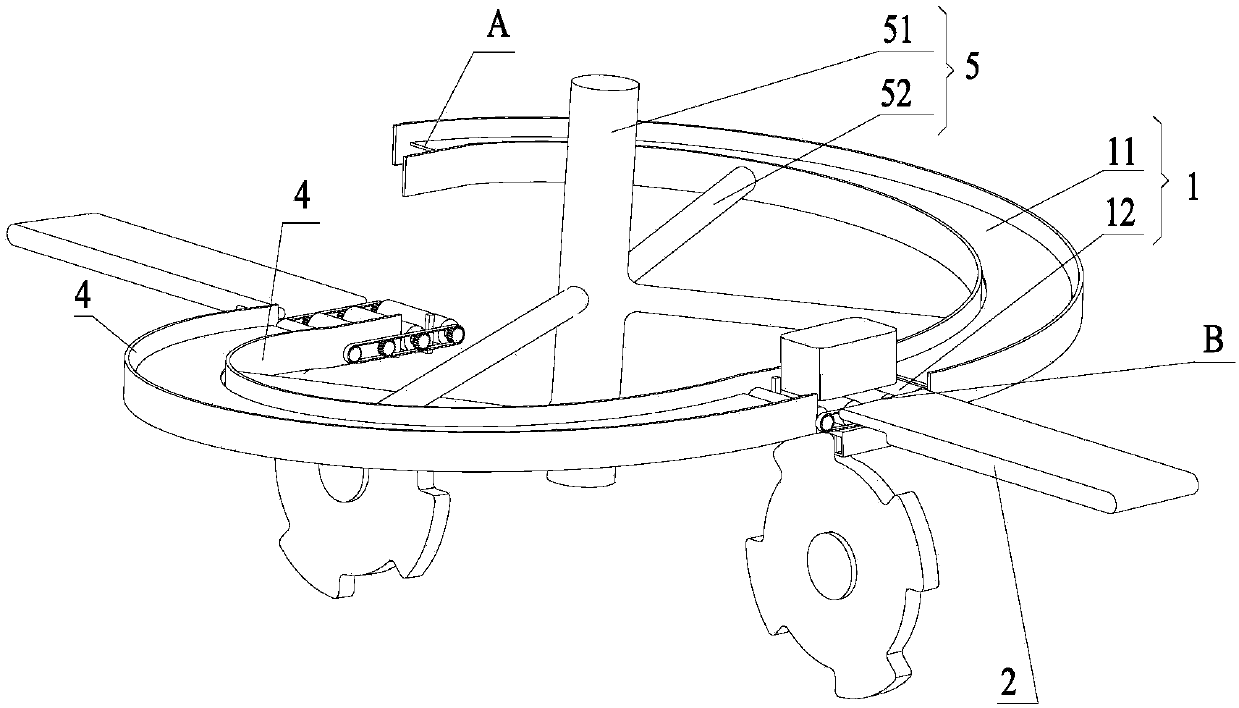

Automatic sorting equipment

The application discloses automatic sorting equipment used for sorting express packages. The automatic sorting equipment comprises a helical conveyor belt and a plurality of second conveyor belts arranged outwards in the radial direction of the helical conveyor belt, wherein the helical conveyor belt comprises a plurality of first conveyor belts and a plurality of sorting parts, which are alternately arranged; and the sorting parts are connected with the second conveyor belts in one-to-one correspondence. The automatic sorting equipment further comprises a plurality of sorting mechanisms which are in contact with the sorting parts in one-to-one correspondence, and the sorting mechanisms are used for sorting the express packages from the sorting parts to the second conveyor belts correspondingly connected with the sorting parts. According to the automatic sorting equipment provided by the application, as the helical conveyor belt is adopted, the space is saved, and automatic implementation of small-scale sites or tail-end sorting is facilitated; and the express packages are dispatched to the second conveyor belts through the sorting mechanisms, the action is stable and quick and the express package sorting efficiency is remarkably improved.

Owner:SF TECH

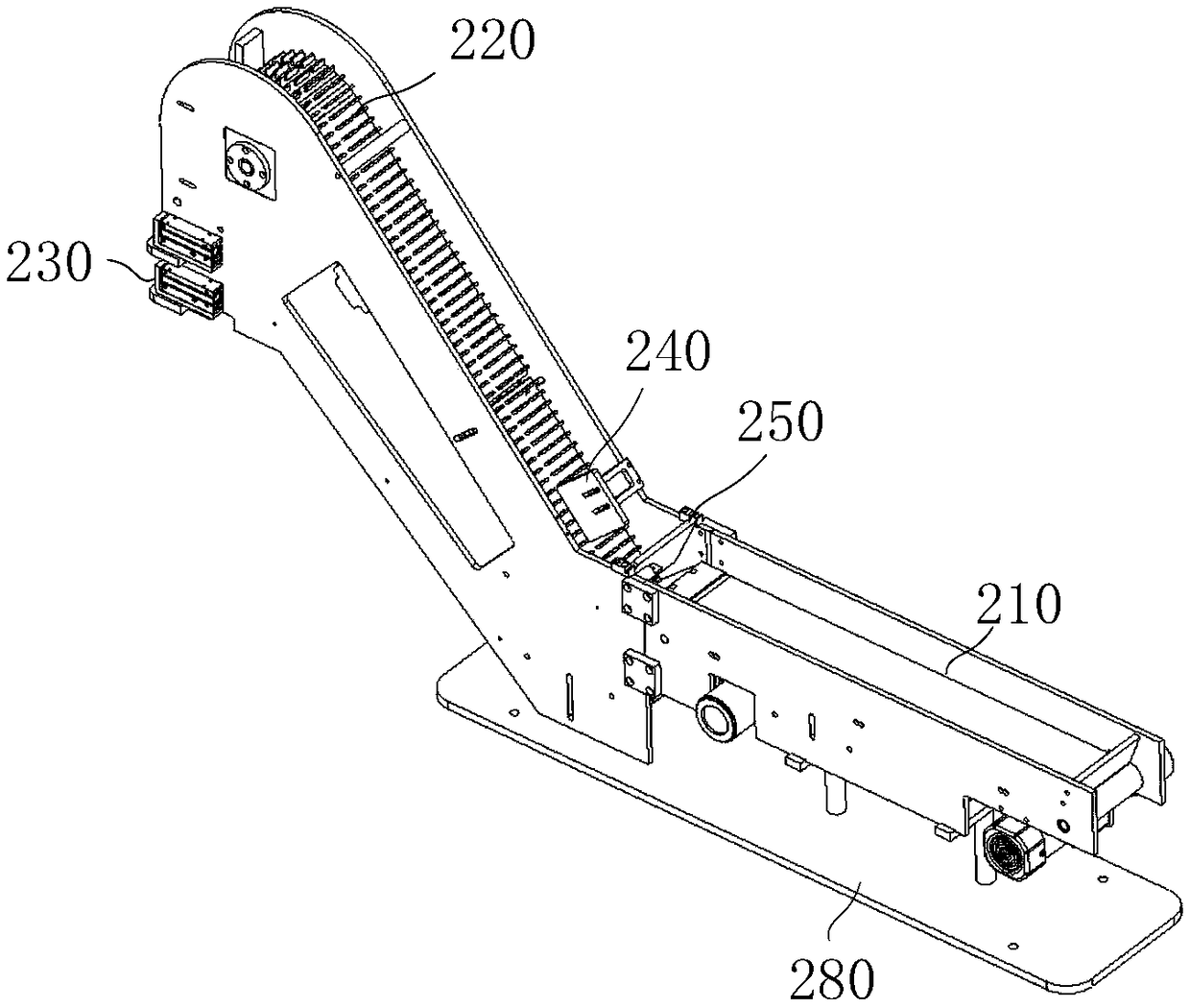

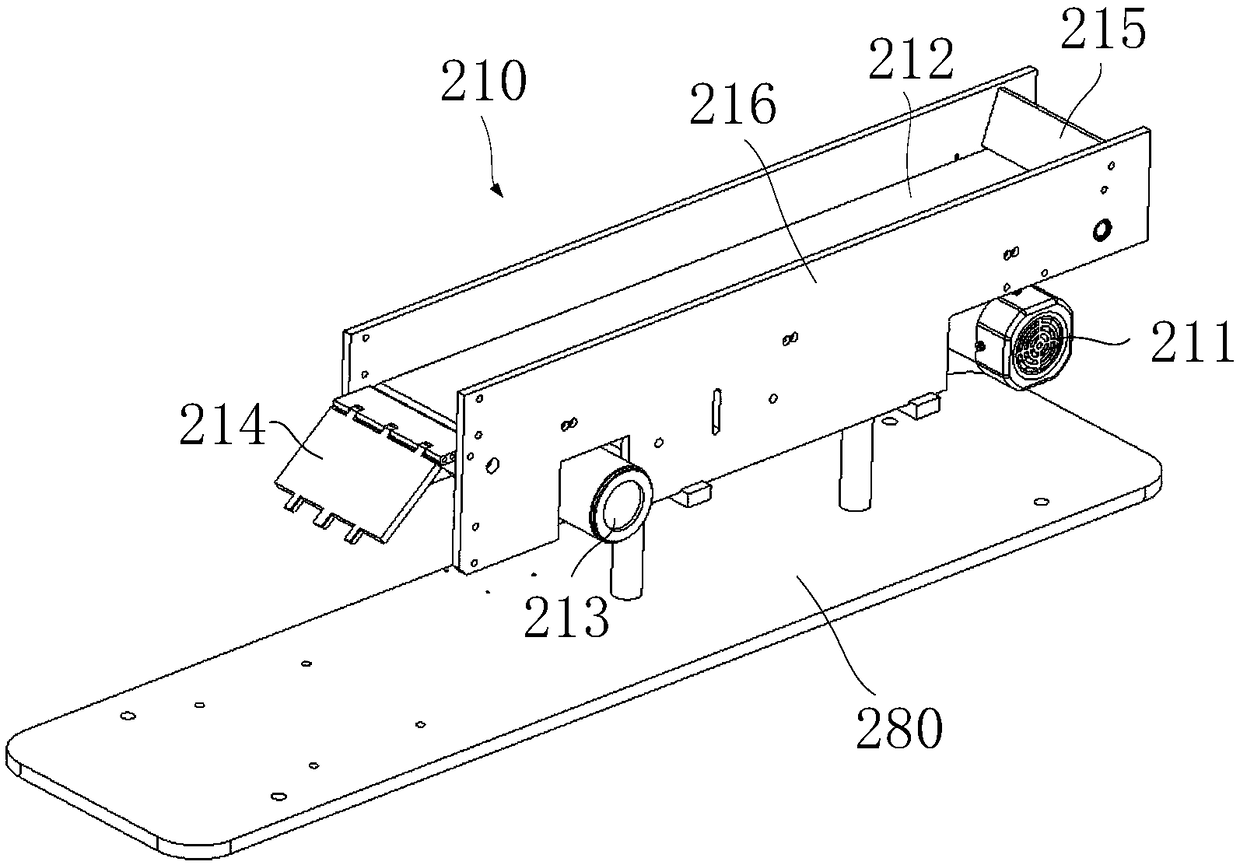

Feeding mechanism used for finished pen packaging

The invention provides a feeding mechanism used for finished pen packaging. The feeding mechanism comprises a feeding body. The feeding body comprises at least two feeding units. The directions of pencaps of finished pens contained in every two adjacent feeding units are different. Each feeding unit comprises a material conveying assembly, a discharging assembly and a releasing assembly. The material conveying assemblies are used for conveying multiple finished pens to the discharging assemblies. The discharging assemblies are used for arranging the finished pens in order and conveying the finished pens to the releasing assemblies. The releasing assemblies are used for releasing a certain number of finished pens. By means of the feeding mechanism, the multiple feeding units are adopted, the multiple rows of finished pens with the pen caps in different directions can be automatically fed, and therefore the finished pen boxing space is saved, the finished pen boxing automation degree isincreased, and the overall production efficiency is improved. The feeding mechanism is reasonable in design, ingenuous in concept, capable of facilitating automatic implementation and beneficial to application and popularization in the pen industry.

Owner:SUZHOU PAIFEITE AUTOMATION TECH CO LTD

Novel hobbing cutter holder capable of realizing fast cutter changing on basis of worm wheel and worm rod

PendingCN109372531AFacilitates automated implementationImprove work efficiencyTunnelsHobbingEngineering

The invention discloses a novel hobbing cutter holder capable of realizing fast cutter changing on basis of a worm wheel and worm rod. The novel hobbing cutter holder solves the technical problems that when an existing disc type hobbing cutter is dismounted, the operation needs to be completed through the cooperation of multiple persons; the time and the labor are wasted. The novel hobbing cutterholder comprises a box body, wherein a C-shaped block and a hobbing cutter are arranged in the box body; one side of a cuter shaft of the hobbing cutter is clamped into the C-shaped block; a hobbing cutter passage is formed in the other side of the cutter shaft; and a worm wheel and worm rod mechanism is also arranged at the other side of the cutter shaft. Through the arrangement of the worm wheeland worm rod mechanism, only the rotation and movement direction of a worm rod needs to be controlled in the dismounting and jacking process of the hobbing cutter; the automatic implementation is convenient; the speed is higher; the convenience is greater; and the work efficiency is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Finished pen packaging device

The invention provides a finished pen packaging device which comprises a packaging box opening mechanism, a combined pen conveying mechanism, a box closing device body and a combining mechanism. The combining mechanism comprises a plurality of combining units, and finished pens with the same number are placed in the combining units. In the vertical direction, pen caps of the finished pens in everytwo adjacent combining units face different directions. The multiple combining units relatively move to the same vertical position, the finished pens fall down from the previous combining unit to thenext combining unit from top to bottom, and the multiple pen caps are combined with the different finished pens. The pen caps are automatically combined with the different finished pens in multiple rows and boxed, the finished pen boxing space is saved, the finished pen boxing automation degree is improved, and the overall production efficiency is improved. The finished pen packaging device is reasonable in design, ingenious in concept, convenient to implement automatically and beneficial to pen industry application and popularization.

Owner:SUZHOU PAIFEITE AUTOMATION TECH CO LTD

Finished pen automatic packaging production line

ActiveCN109502087BSave box spaceHigh degree of automationRod-shaped articlesStacking articlesProduction linePalletizer

The invention provides an automatic packaging production line for finished pens. The automatic packaging production line comprises a packaging device body. The packaging device body comprises a feeding body, a packaging box opening mechanism, a material combining conveying mechanism, a box closing device body, a stacking mechanism, a material combining mechanism and a detecting device. By means ofthe automatic packaging production line for the finished pens, automatic feeding, filling, packaging and stacking of the finished pens are achieved, the blank of an automatic production line of the pen industry is filled up, meanwhile, the finished pen boxing space is saved, the finished pen boxing automation degree is improved, and the overall production efficiency is improved. The automatic packaging production line for the finished pens is reasonable in design, ingenious in concept and capable of facilitating automatic implementation and facilitating pen industry application and popularization.

Owner:SUZHOU PAIFEITE AUTOMATION TECH CO LTD

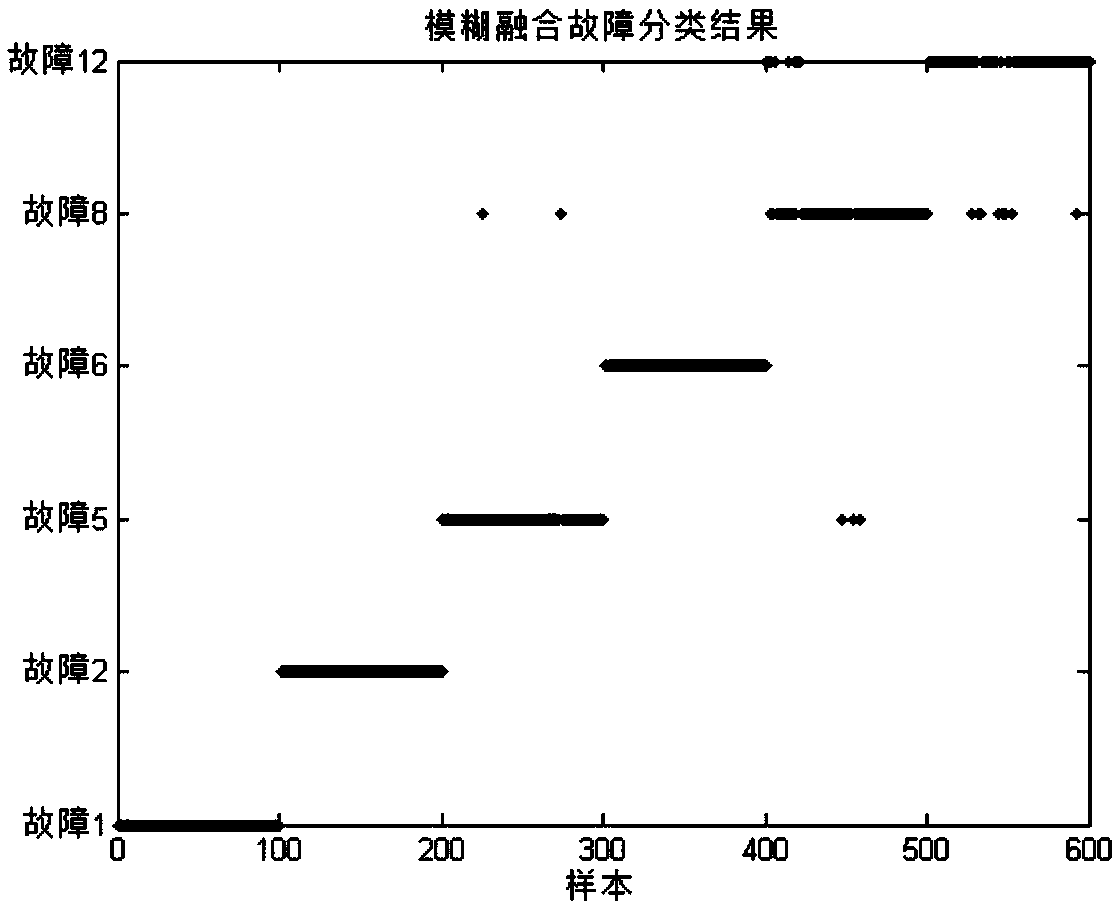

A Classification Method for Industrial Process Faults Based on Analytic Hierarchy Process and Fuzzy Fusion

ActiveCN106371427BImprove monitoring effectFacilitates automated implementationElectric testing/monitoringData setAlgorithm

Owner:ZHEJIANG UNIV

Formula of novel logistics tray

The invention discloses a formula of a novel logistics tray. The logistics tray is composed of the following components: 88.2% of PP (polypropylene), 2.0%-5.0% of HDPE (hot melt resin), 0.10%-0.30% ofa defoaming agent, 0.10%-5.0% of POE (thermoplastic elastomer), 1.8% of color masterbatch, 0.10%-1.6% of a sodium hydroxide solution with a concentration of 30% and 0.10%-4.6% of a degreasing mixed solution. According to the formula of the novel logistics tray, the degreasing mixed solution is added into the raw materials of the formula for mixing, so the surface energy of the prepared logisticstray is effectively improved, and the phenomenon of poor cementing effect is avoided; the logistics tray is soaked, so the surface energy and smoothness of the logistics tray are further improved; andthe whole formula is convenient to automatically implement, and the loss of logistics caused by poor cementing effect can be effectively reduced.

Owner:上海上南复盘物流设备集团有限公司

Soft sensor modeling method for industrial process based on collaborative training partial least squares model

InactiveCN104914723BImprove predictive performanceIncrease dependenceAdaptive controlStudy methodsLearning methods

The invention discloses a soft measurement research method for the industrial production process under the condition that the number of available training samples is small, which is applied to carrying out soft measurement modeling under the condition that modeling data is small in amount and realizing prediction for product information. According to the invention, an effective linear prediction model is established by using a cooperative training based partial least squares learning method, a problem of low model precision under the condition that sampling data of the industrial production process is small in amount, and the predication accuracy and the performance of the model established in allusion to the process are improved, thereby enabling the industrial production process to be more reliable, and enabling the product quality to be more stable.

Owner:ZHEJIANG UNIV

Lithium battery winding core tab detection device and lithium battery production line

ActiveCN109752386BWon't hurtGuaranteed work efficiencyFinal product manufactureSecondary cellsStructural engineeringMechanical engineering

The invention relates to the field of lithium battery production detection, and discloses a lithium battery winding core tab detection device and a lithium battery production line, wherein an adjustment mechanism for bending a horizontal tab (5) is installed on a frame (1) ( 2), the adjustment mechanism (2) includes a bending plate (3) used to bend the tab (5), during detection, after the tab (5) collides with the bending plate (3) and the adjacent tab is bent (5) The gap between the outer ends of the sheets becomes larger, and the bent plate (3) includes a transparent plate (4). During detection, the tab (5) is in contact with the transparent plate (4). By bending the lugs to increase the distance between the ends, the vision system can be used on the detection lugs, which greatly improves the detection efficiency, saves manpower, reduces labor intensity, and facilitates automatic implementation.

Owner:浙江双元科技股份有限公司

An Integrated Semi-Supervised Fisher Discriminant Based Fault Classification Method for Industrial Processes

InactiveCN106649789BImprove monitoring effectFacilitates automated implementationRelational databasesCharacter and pattern recognitionDiscriminantDimensionality reduction

The invention discloses an integrated semi-supervised Fisher's discrimination-based industrial process fault classifying method. In the method, offline modeling is first conducted; non-labeled data is randomly sampled and together with labeled data form a plurality of random training subsets; then semi-supervised Fisher dimensionality reduction is conducted to acquire a plurality of Fisher's discrimination matrixes; sampled data with dimensionality reduction is operated according to a Bayesian statistics method to acquire a series of posterior probability matrixes; the posterior probability matrixes of the labeled data and corresponding labels work as training samples adjacent to a measurement layer fusion algorithm K; during online classification, above semi-supervised Fisher's discrimination classifiers are called to acquire a posterior probability matrix of each online to-be-measured sample; and then the posterior probability matrix is input to a measurement layer fusion K adjacent classifier to acquire a final fault classification result. Compared with other methods, industrial process fault classification effect can be improved, knowledge and operation confidence to the process can be enhanced for operators and automatic implantation of the industrial process can be facilitated.

Owner:ZHEJIANG UNIV

A Formal Description and Decomposition Method of Metamorphic Relationship

ActiveCN103713997BFacilitates automated implementationPrecise formal descriptionSoftware testing/debuggingApplicability domainDecomposition

The invention discloses a formal description and decomposition method for a metamorphic relation. The method includes the following steps: (1) according to targeted tested software, extracting and designing the metamorphic relation that the software mush satisfy to create the metamorphic relation; (2) performing formal modeling on the obtained metamorphic relation on the basis of symbolic logic, determining constraint conditions under which the metamorphic relation is established, performing formal description, then describing input parameters and output parameters of the metamorphic relation on the basis of the symbolic logic, and establishing a formal description model of the metamorphic relation; (3) on the basis of the formal model, respectively extracting subrelations forming the metamorphic relation and a set description form of a metamorphic relation composition model, and establishing a metamorphic relation decomposition model. The method is simple and clear, description capacity and application range of the formal model are guaranteed through symbolic logic description, the accurate, standard and effective method is provided for description of the metamorphic relation, and the method is more conducive to automated implementation of subsequent metamorphic testing.

Owner:PLA UNIV OF SCI & TECH

Control method of penicillin production process based on collaborative training lwpls

InactiveCN105425583BImprove predictive performanceHigh precisionAdaptive controlPenicillinStudy methods

The invention discloses a control method of a penicillin production process of cooperative training and Local Weighted Partial Least Squares (LWPLS), and the control method is used for soft measurement modeling under the condition that the quantity modeling data is relatively small and realizing prediction of product information of a penicillin production process. According to the control method, an effective linear prediction model is established by using a cooperative training-based local weighted partial least squares learning method, the problem of low model precision under the condition that the quantity of sampling data of the penicillin production process is too small is overcome, and the predication accuracy and the performance of the model established directing at the process are improved, thereby enabling the penicillin production process to be more reliable, and enabling the product quality to be more stable.

Owner:ZHEJIANG UNIV

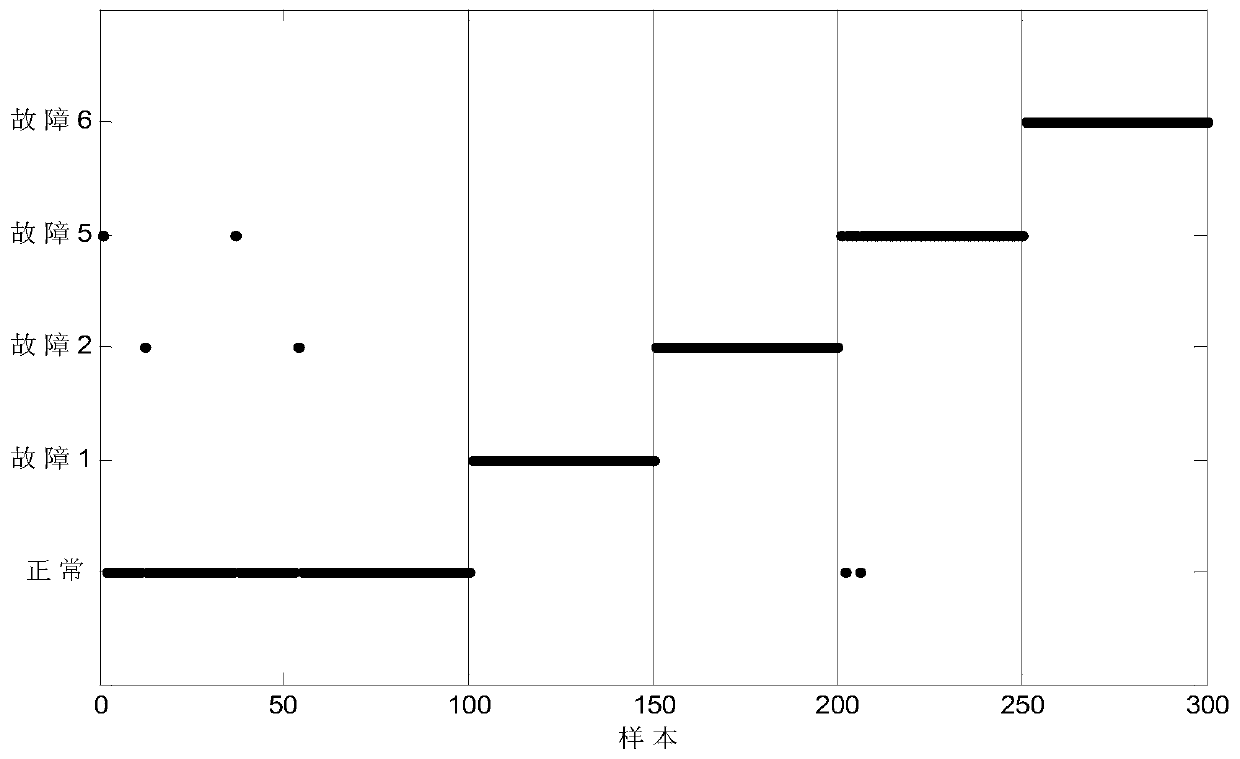

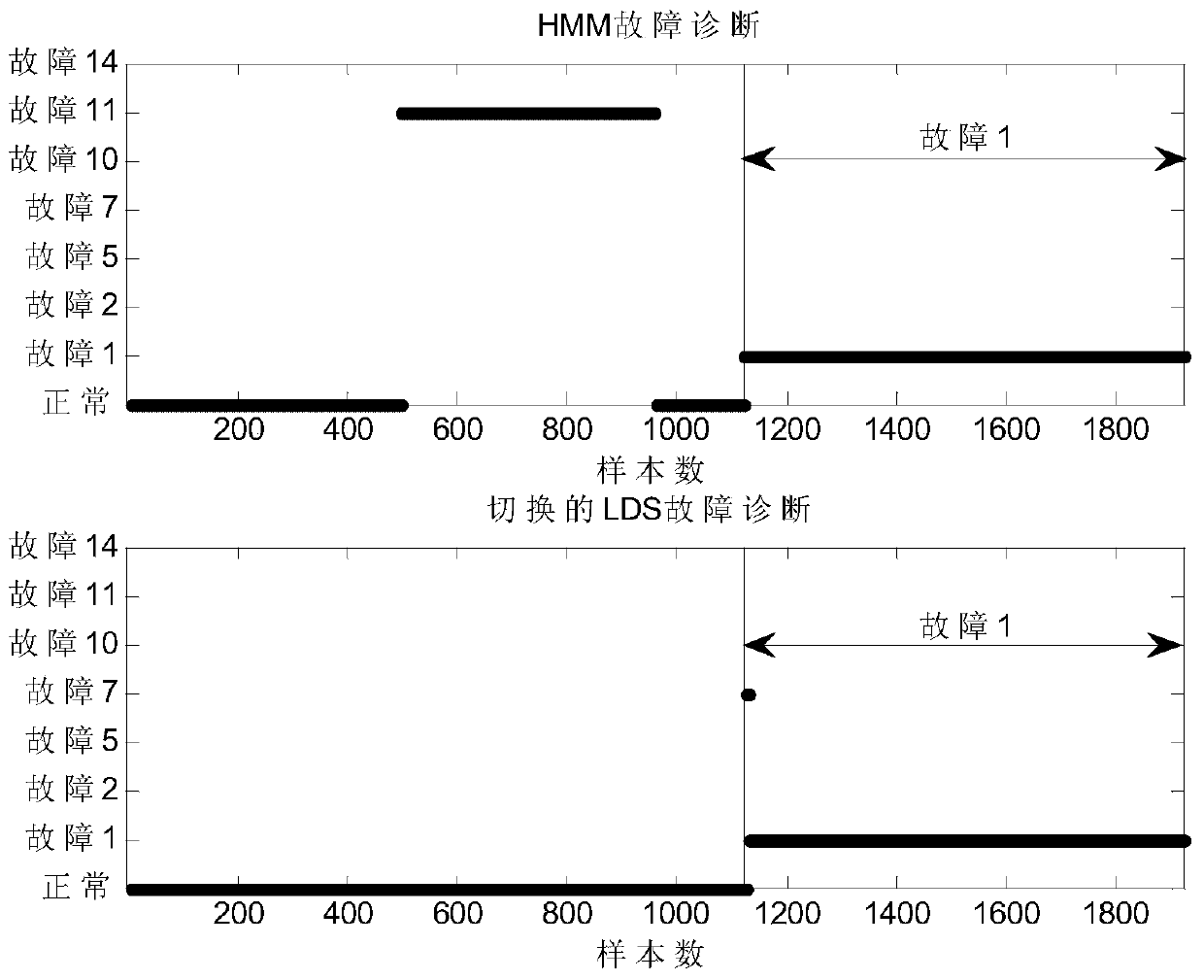

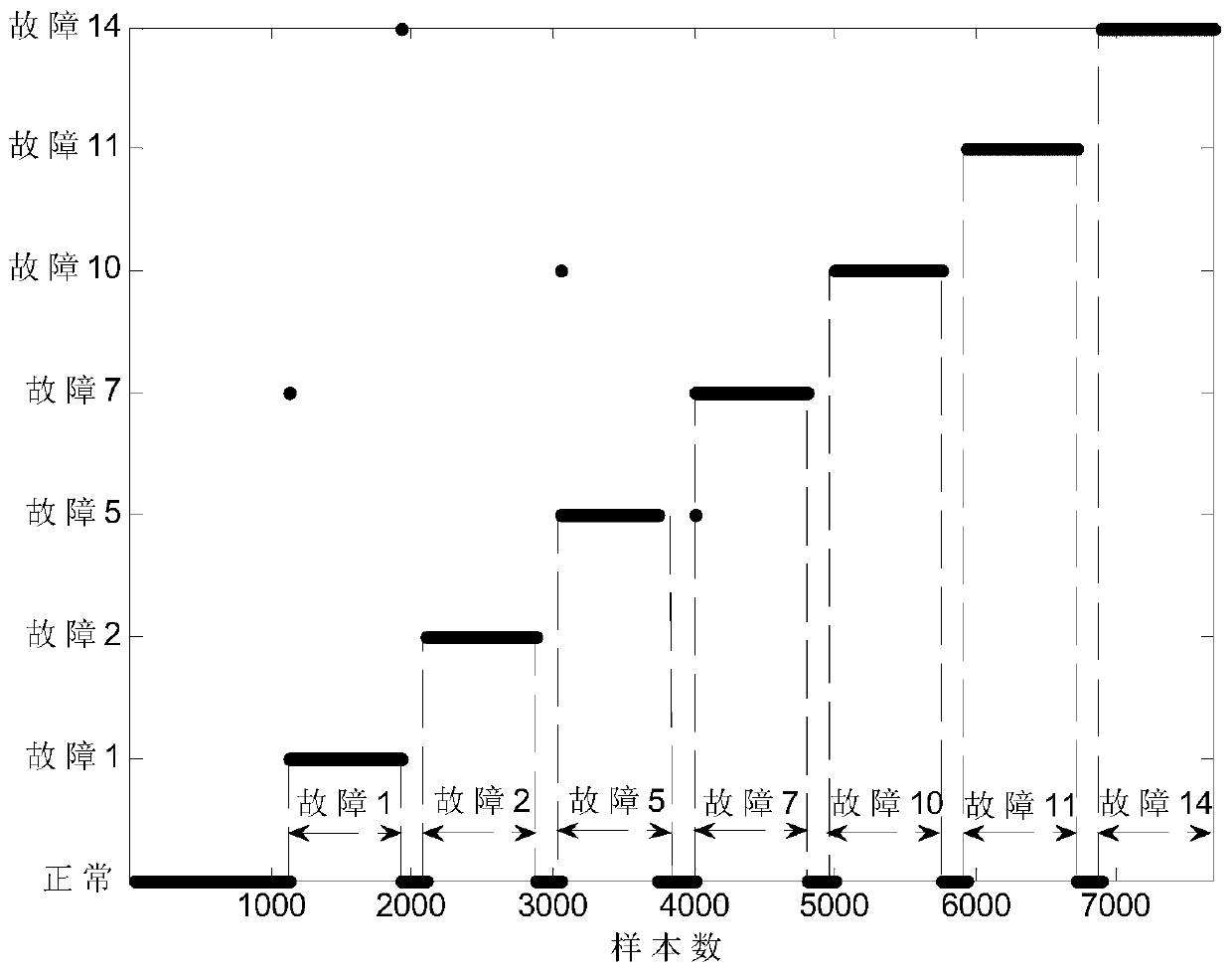

Fault Diagnosis Method of Industrial Process Based on Switched Linear Dynamic System Model

InactiveCN104914850BIncrease dependenceImprove fault diagnosis abilityElectric testing/monitoringDiagnosis methodsDynamic system model

The invention discloses an industrial process fault diagnosis method based on a switching linear dynamic system model. The method comprises the steps of firstly carrying out independent repeated sampling on normal operation data and various known fault data of the industrial process, and then establishing the switching linear dynamic system model through a learning algorithm of the switching linear dynamic system model; and then acquiring a diagnosis result of the current monitoring data by using a Gaussian sum filtering method, that is, judging whether the current data is located at a normal operating condition, and if not, judging which fault the current data is located. Compared with other method at present, the industrial process fault diagnosis method not only improves a fault diagnosis effect of the industrial process, enhances mastering of a process operator for the process state, enables industrial production to be safer, and enables the product quality to be more stable. In addition, the industrial process fault diagnosis method improves the dependency of a fault diagnosis method for process knowledge to a great extent, thereby being more conducive to automation implementation of the industrial process.

Owner:ZHEJIANG UNIV

Semiconductor process monitoring method based on independent component analysis and Bayesian inference

InactiveCN101713983BImprove monitoring effectFacilitates automated implementationTotal factory controlProgramme total factory controlIndependent component analysisAnalysis method

The invention discloses a semiconductor process monitoring method based on independent component analysis and Bayesian inference, comprising the following step of: firstly, dividing working conditions according to the mixed data of the semiconductor process, conducting the independent component analysis for each working condition data, and establishing a corresponding independent component analysis model; and then integrating and combining the monitoring information under the different working conditions by a Bayesian inference method to obtain a final monitoring result. In addition, the invention can also acquire the working condition information of current monitoring data by a posterior probability analysis method, that is to say, the invention can judge that the current monitoring data is in what process operation working condition; compared with the present other methods, the invention can not only greatly enhance the monitoring effect of the semiconductor process, but also largely improve the dependence of the monitoring method on process knowledge and enhance the comprehensive ability and the operating confidence of process operators on the process, thereby being more beneficial to the implementation of the automation of the semiconductor process.

Owner:ZHEJIANG UNIV

Automatic hoisting equipment, hoisting method and lifting method

PendingCN112479001ASimple stepsEasy to automateConverting sensor output electrically/magneticallySafety gearControl systemAutomation

The invention discloses automatic hoisting equipment, a hoisting method and a lifting method. The hoisting equipment comprises an electric permanent magnet lifting appliance used for hoisting a workpiece and a connecting device connected with a hoisting trolley, and the electric permanent magnet lifting appliance is movably connected to the connecting device in the vertical direction; and the automatic hoisting equipment further comprises a detection device used for detecting the relative position relation between the electric permanent magnet lifting appliance and the connecting device and feeding back a detection signal to a control system so as to control whether the electric permanent magnet lifting appliance carries out adsorption and release actions on the workpiece or not. The automatic hoisting equipment has the advantages of being simple, practical, capable of reducing the labor intensity of personnel and effectively reducing errors and risks, high in automation degree and thelike, the hoisting method and the lifting method have the advantages that besides the advantages, the steps are simple, operation is easy and convenient, and safety can be improved while hoisting ofa single piece is guaranteed.

Owner:ZHUZHOU HVR MAGNETICS

Fault Classification Method Based on Adaptive Ensemble Semi-Supervised Fisher Discriminant

InactiveCN106843195BImprove monitoring effectFacilitates automated implementationElectric testing/monitoringClassification methodsEngineering

The invention discloses an industrial process fault classification method based on self-adaption integrated semi-supervision Fisher discrimination. The method comprises the steps of when off-line modeling is conducted, firstly conducting off-line modeling on unlabeled data, and constituting a semi-supervision random training subset by combining labeled data with the unlabeled data; when iteration training is conducted on a sub classifier each time, conducting semi-supervision Fisher dimensionality reduction to obtain a Fisher discrimination matrix, and obtaining a posterior probability matrix, a combined weight of the sub classifier and a sample weight of the labeled data during next time iteration with the labeled sample data after dimensionality reduction according to a Bayesian statistics method; adopting the posterior probability matrix of the labeled data and a label of the matrix as a training set of a fusion algorithm K near neighbor; during online classification, calling each sub classifier to obtain the posterior probability matrix of an online sample to be detected, and inputting the posterior probability matrix into a fusion K near neighbor classifier with the weight to obtain a final result. Compared with an existing method, the industrial process fault classification method based on the self-adaption integrated semi-supervision Fisher discrimination improves the fault classification result of an industrial process, and more facilitates automated implementation of the industrial process.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com