Safety filter based on coupling principle and manufacturing method of safety filter

A filter and safety technology, which is applied in the field of medical devices, can solve the problems that the bubble point characteristics of the filter membrane cannot function, cannot be bonded or welded, and the joint surface leaks, etc. It is easy to implement manually or automatically, and the mass production is stable. The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

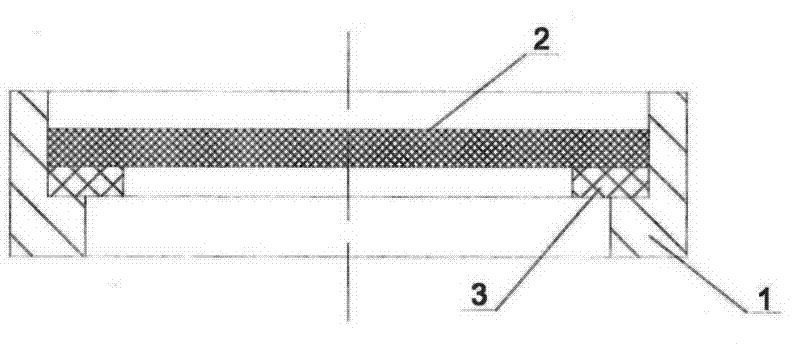

[0022] Such as figure 1 and 2 The shown safety filter includes a filter membrane holder 1 and a filter membrane 2. The filter membrane holder 1 is circular, and the edge of the filter membrane 2 is tightly welded on the welding surface 11 of the filter membrane holder 1. The filter membrane holder 1 and the A coupling layer 3 is arranged between the filter membranes 2 . Wherein, the coupling layer 3 is a thin film, and the thin film is circular.

Embodiment 2

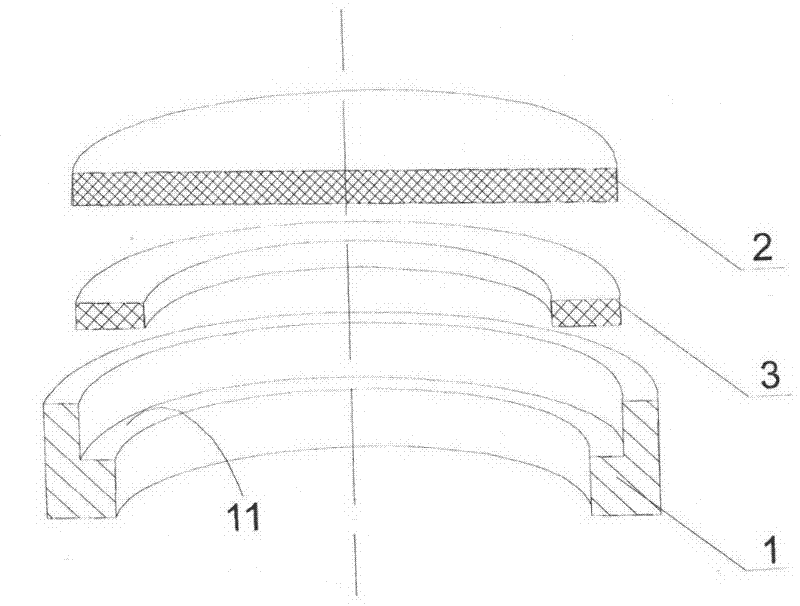

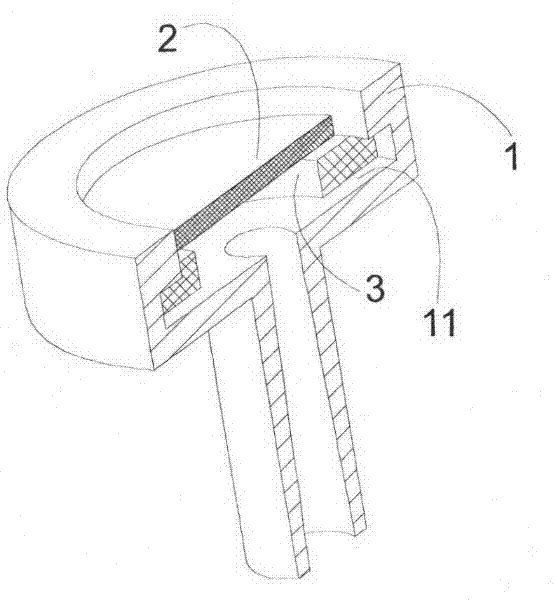

[0024] Such as image 3 The shown safety filter includes a filter membrane support 1 and a filter membrane 2. The filter membrane support 1 is bowl-shaped, and the edge of the filter membrane 2 is tightly welded on the welding surface 11 of the filter membrane support 1. The filter membrane support 1 and the filter membrane A coupling layer 3 is arranged between the membranes 2 . Wherein, the coupling layer 3 is a material layer formed based on the secondary injection molding process, and the material layer is in the shape of a ring.

[0025] The manufacturing method of above-mentioned safety filter based on coupling principle is:

[0026] This method requires at least the components including the filter membrane holder 1 and the filter membrane 2 and the sealing fixture, wherein the material of the filter membrane holder 1 must be able to be directly bonded to the catheter of the infusion set, and the material of the filter membrane 2 cannot be compatible with the filter mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com