Electric pressure cooker with sliding spring plate

An electric pressure cooker and shrapnel technology, applied in pressure cookers and other directions, can solve the problems of reducing the service life of the pressure switch, out of control of abnormal pressure control, failing to meet safety requirements, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

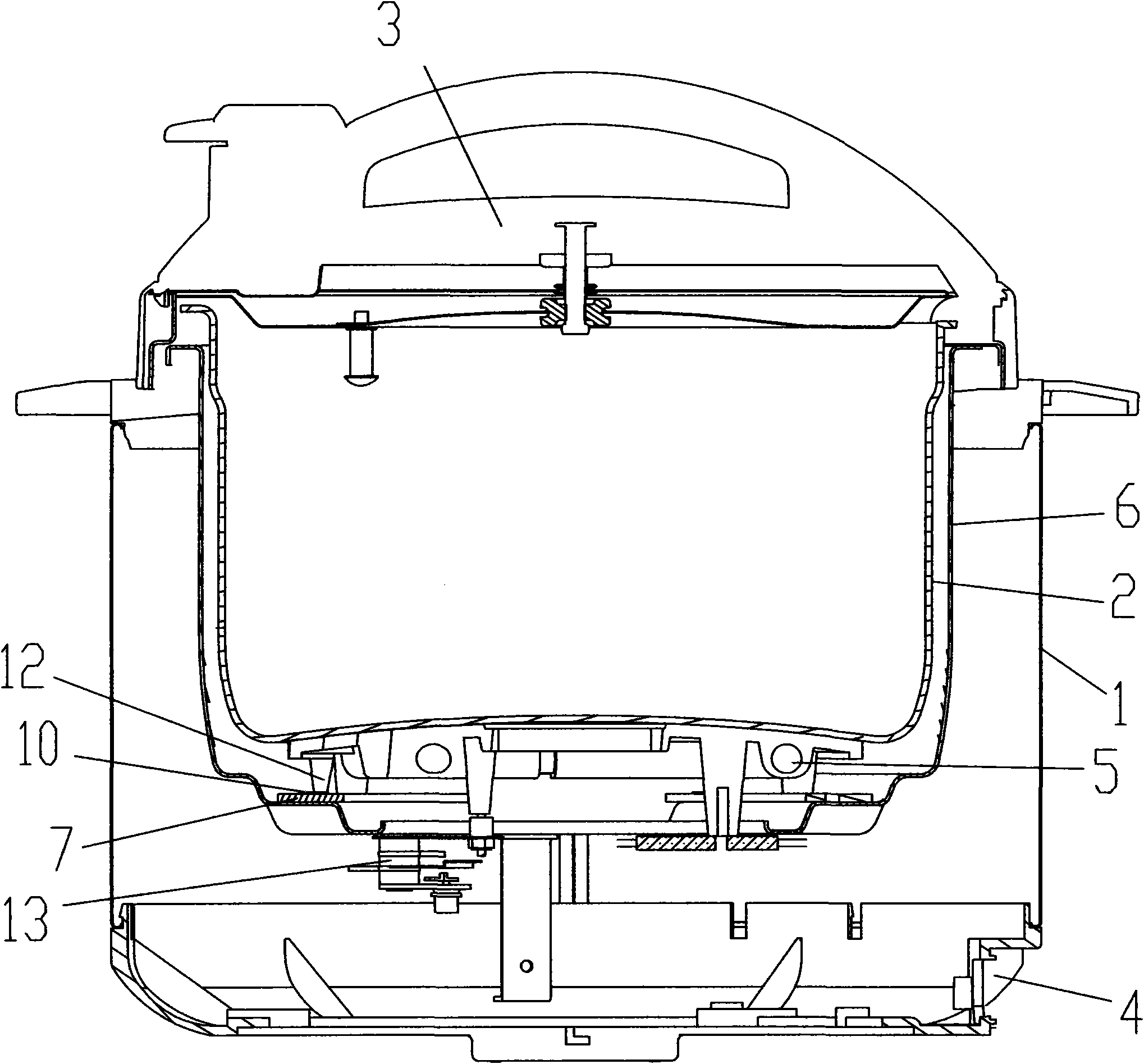

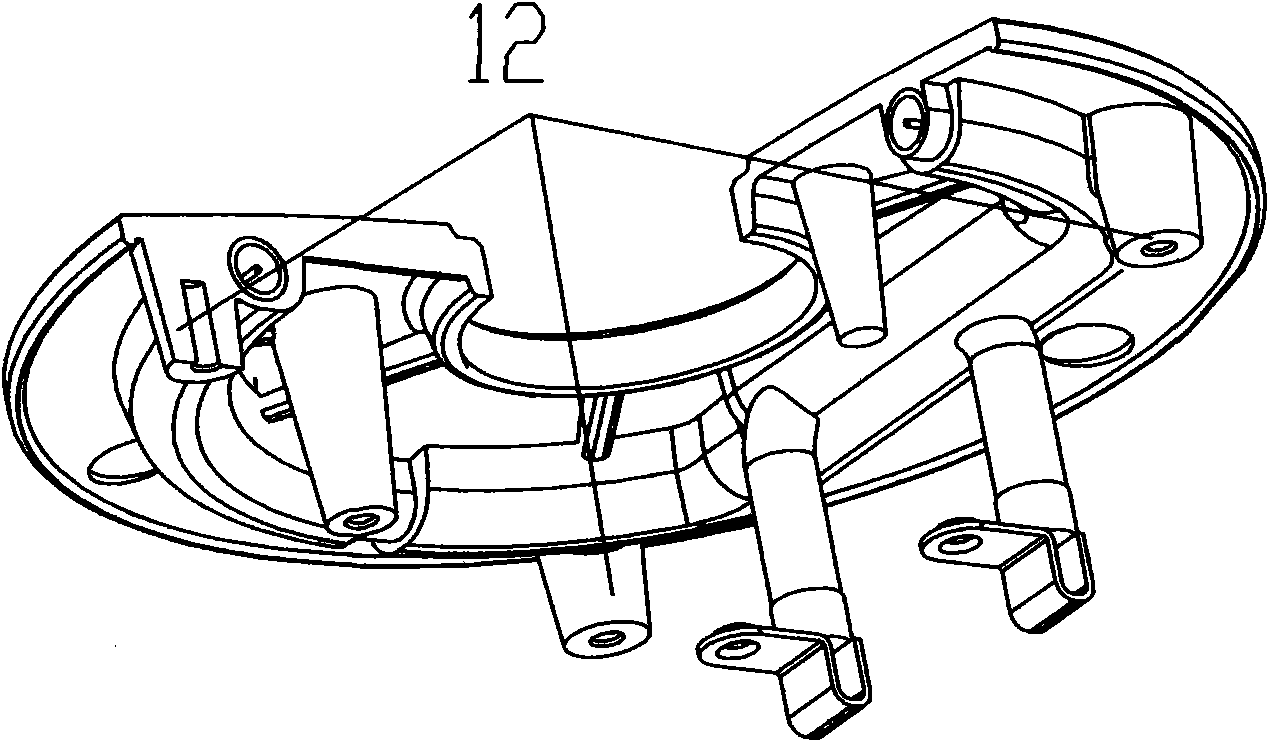

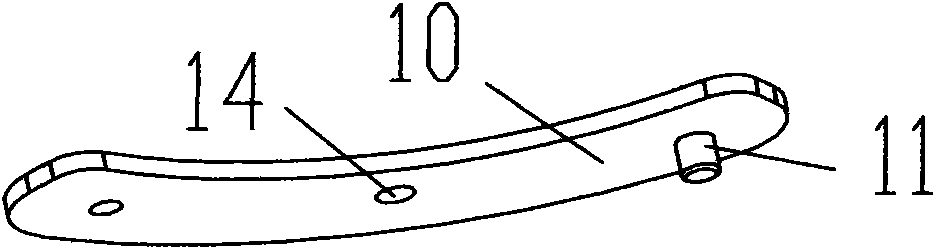

[0023] An electric pressure cooker with sliding shrapnel, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a pot body 1, an inner pot 2, a pot cover 3, a base 4, and an electric heating plate 5. The inner pot 2 is placed in the pot body 1, the pot cover 3 is installed above the pot body 1, and the electric heating plate 5 is installed on the base. 4, there are 3 pairs of bosses 7 arranged on the inner bottom of the middle layer 6 by the side wall; the upper ends of the bosses 7 leave spaced holes 8 and fixing holes 9 alternately; The other end of the shrapnel 10 is provided with a boss 11, and the boss 11 is placed in the limit hole 8; the back of the electric heating plate 5 is provided with a bump 12 matching the boss 7, and the bump 12 is connected with the sliding shrapnel 10; The pressure switch 13 is directly installed on the outer bottom of the middle layer 6 . There are three pairs of said bosses 7; the bumps 12 are correspondingly matche...

Embodiment 2

[0025] With embodiment 1. The difference is: the sliding shrapnel is crescent-shaped. The bosses 7 are arranged in four pairs, and the bosses 7 are arranged in a quadrangular shape on the inner bottom of the middle layer 6 .

[0026] Working principle: When the power is turned on, the electric heating plate is heated, the water-containing food in the inner pot is heated and evaporated, and the steam generates pressure in the inner pot. Since the middle layer of the pot lid is rigidly connected, the pressure is transmitted to the electric heating plate through the inner pot, and the electric heating plate will The pressure is transmitted to the shrapnel, the shrapnel produces elastic deformation, the inner pot and the electric heating plate move downward at the same time, and the pressure switch is driven at the contact point of the electric heating plate with the pressure switch; when a certain displacement is reached, the pressure switch is disconnected to cut off the power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com