Lithium battery winding core tab detection device and lithium battery production line

A detection device, lithium battery technology, applied in the direction of measuring devices, secondary batteries, electrochemical generators, etc., can solve the problems of low efficiency, manual detection, high work intensity, etc., to achieve reduced labor intensity, long service life, The effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

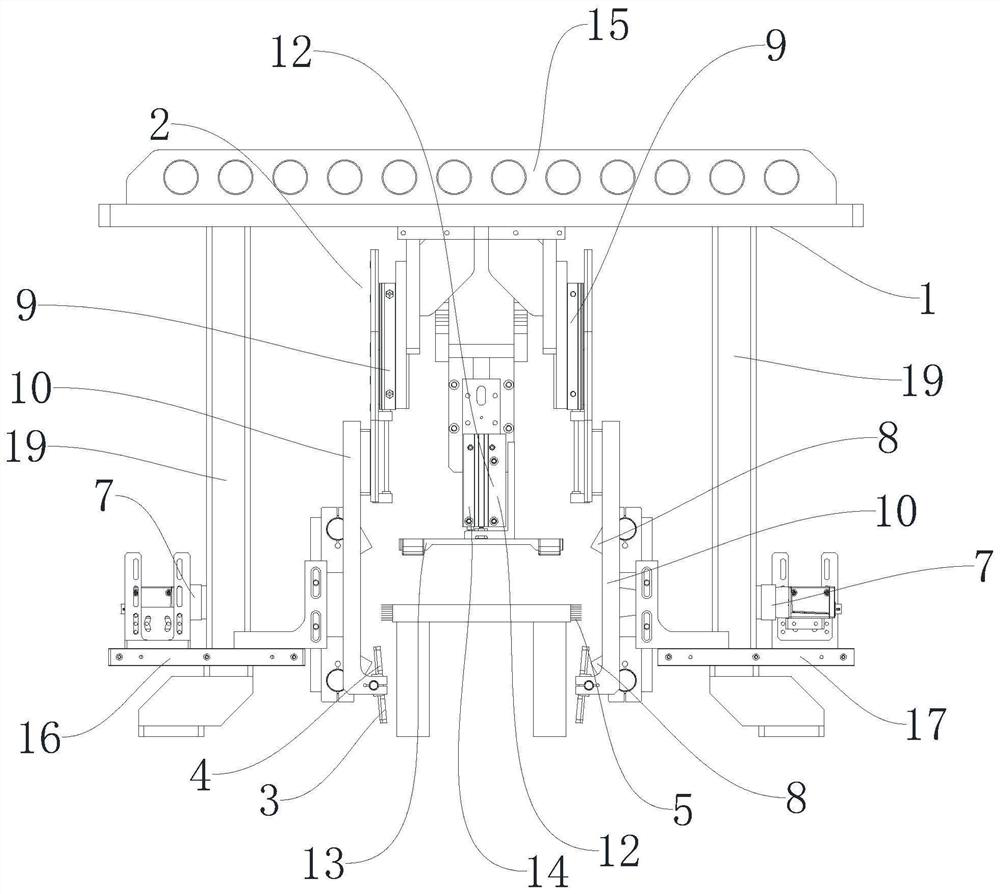

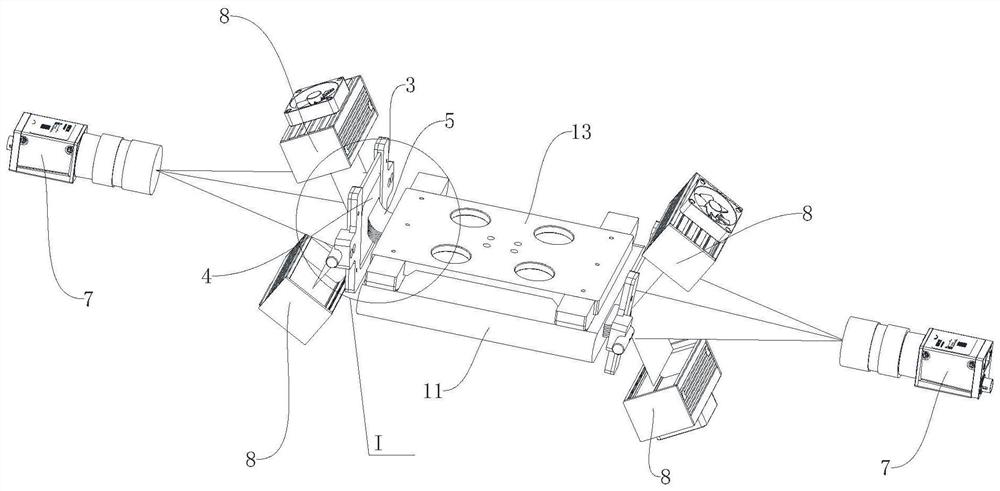

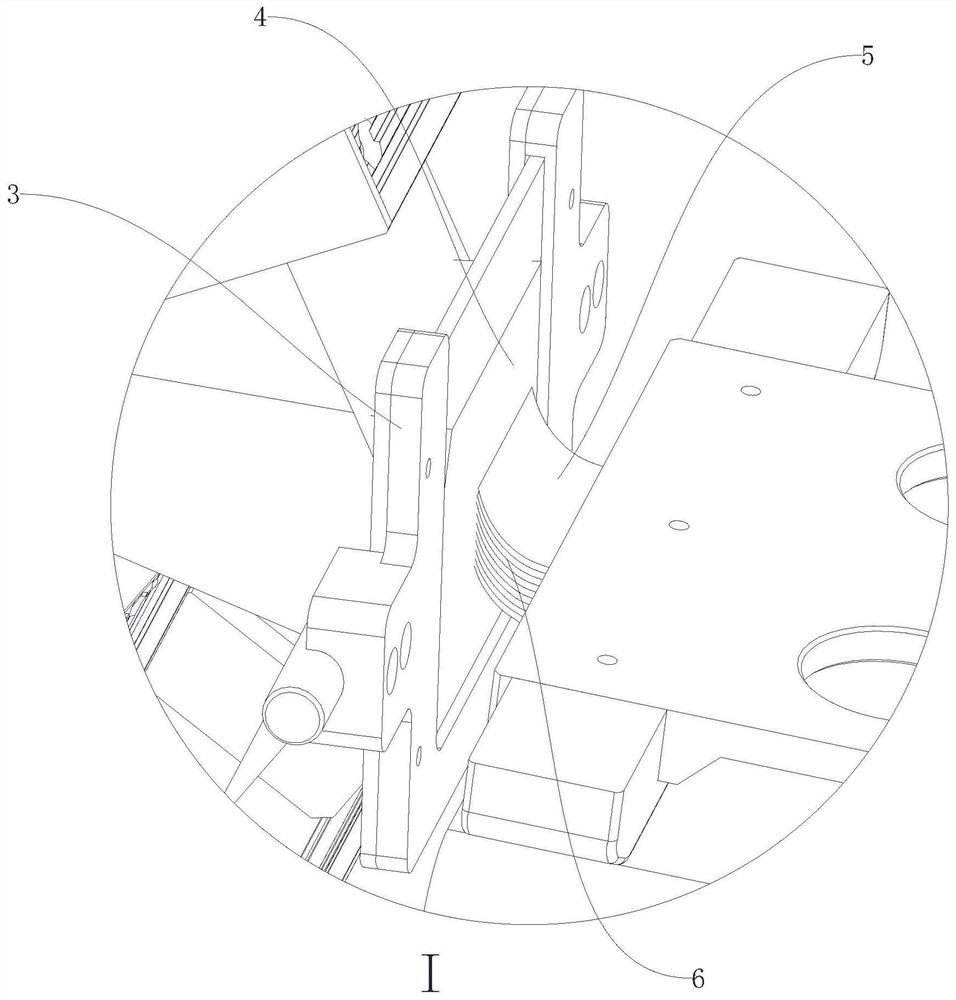

[0027] Such as Figures 1 to 7 As shown, a lithium battery winding core tab detection device includes a frame 1, an adjustment mechanism 2 for bending the horizontal tab 5 is installed on the frame 1, and an adjustment mechanism 2 for bending the tab is installed on the adjustment mechanism 2. The bending plate 3 of 5, when detecting, the gap between the outer ends of the adjacent 5 pieces of tabs becomes larger after the tab 5 collides with the bending plate 3, and the gap between the outer ends of the adjacent tabs becomes larger. , the tab 5 is in contact with the transparent plate 4 . The bending here only refers to the bending without destroying the pole piece 6. Since the pole piece 6 of the tab 5 is made of elastic metal sheet, the pole piece 6 has a certain deformation recovery ability, and the purpose of bending the pole piece 6 is only for By increasing the distance between the ends of adjacent pole pieces 6, the tabs 5 can return to a horizontal state after the con...

Embodiment 2

[0036] Such as Figure 1 to Figure 7 As shown, a lithium battery winding core tab detection device is different from Embodiment 1 in that a "eight" shape with an opening downward is formed between the two bent plates 3, and the initial position of the mounting frame 10 is At the upper end, when testing, the adjusting cylinder 9 drives the mounting frame 10 to move down to conflict with the pole lug 5 .

Embodiment 3

[0038] Such as Figure 1 to Figure 7 As shown, a detection device for lithium battery core tabs differs from Embodiment 1 in that the number of bent plates 3 in this embodiment is one, and the number of cylinders 9 and mounting frames 10 is adjusted accordingly. for one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com