Automatic hoisting equipment, hoisting method and lifting method

A hoisting equipment and automatic technology, applied in the direction of safety devices, transportation and packaging, load hanging components, etc., can solve the problems of non-adjustable magnetic penetration depth, difficult, laborious operation, etc., and achieve the effect of easy automatic implementation and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

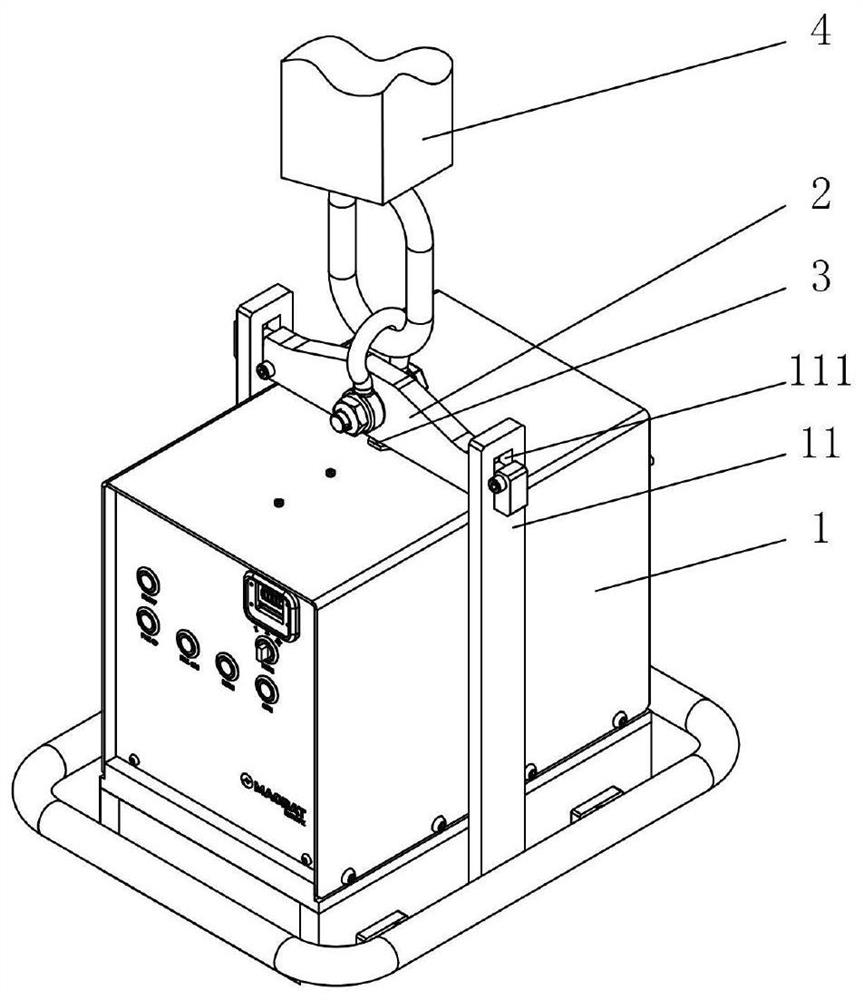

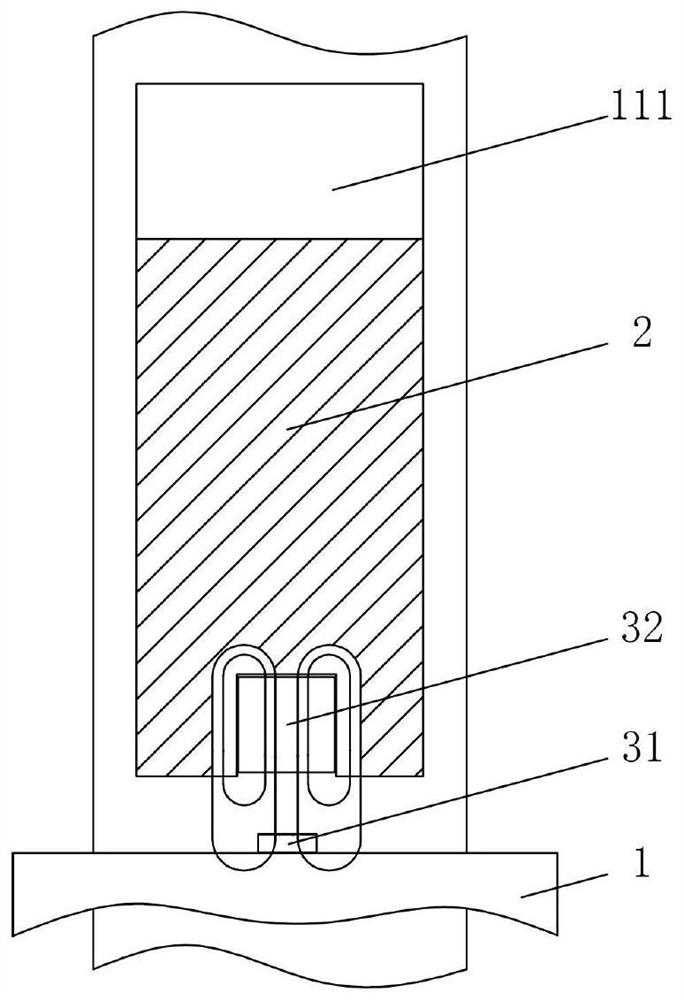

[0052] Such as figure 1 As shown, the automatic hoisting equipment of this embodiment includes an electro-permanent magnet hoist 1 for hoisting workpieces and a connecting device 2 connected to the hoisting trolley 4, and the electro-permanent magnet hoist 1 is movably connected to the connection in the vertical direction On the device 2, the automatic hoisting equipment also includes a device for detecting the relative positional relationship between the electro-permanent magnet hoist 1 and the connecting device 2, and feeding back the detection signal to a control system to control whether the electro-permanent magnet hoist 1 performs adsorption on the workpiece. And the detection device 3 of release action. Since the electro-permanent magnet hoist 1 and the connecting device 2 can move along the vertical direction, the positional relationship between the two will change when the hoisting equipment is hoisted and landed.

[0053] During the hoisting process, the automatic h...

Embodiment 2

[0081] This embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, such as Figure 4As shown, the detection device 3 includes a proximity switch 33. The proximity switch 33 is installed on the electro-permanent magnet hanger 1 or the connection device 2. The proximity switch 33 can flexibly capture the distance between the electro-permanent magnet hanger 1 and the connection device 2. Changes in positional relationships. The distance between the electro-permanent magnet lifter 1 and the connecting device 2 detected by the proximity switch 33 is less than the second set value, that is, when the hoisting equipment lands, the electro-permanent magnet lifter 1 is controlled to perform the adsorption or release action on the workpiece, which is greater than the second set value value, that is, control the electro-permanent magnet lifter 1 to maintain the state before it is greater than the second set value when the hoisting equipment is hoisted...

Embodiment 3

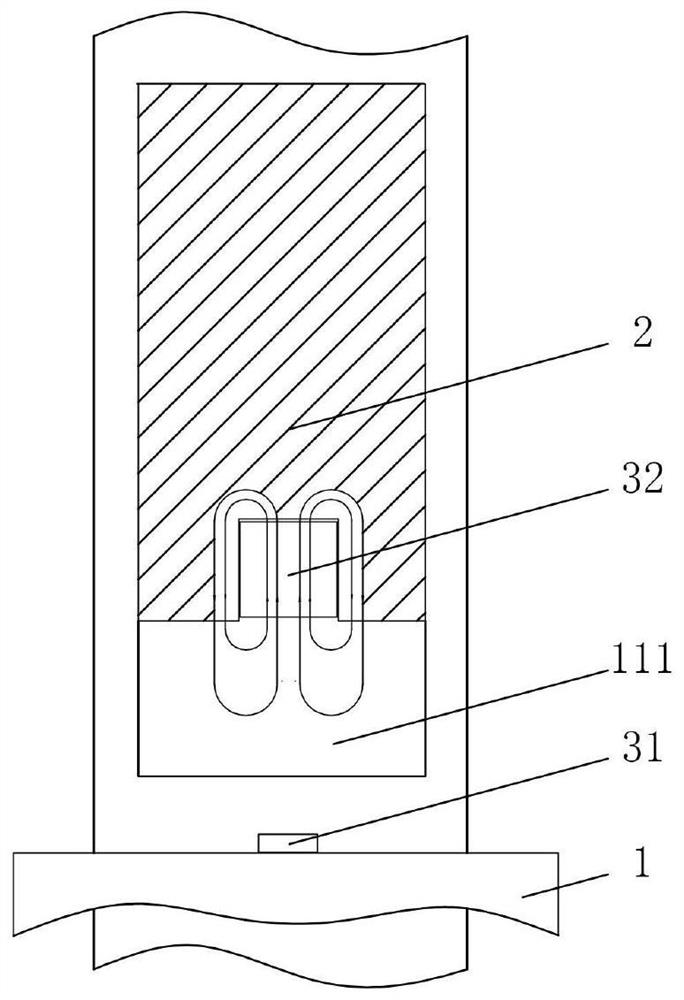

[0084] This embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, such as Figure 5 As shown, the detection device 3 includes a contact switch 34 , and the contact switch 34 is disposed at at least one end of the strip-shaped hole 111 in the vertical direction. The contact switch 34 can stably detect the positional relationship between the connecting device 2 and the electro-permanent magnet hanger 1 .

[0085] When the contact switch 34 is arranged on the top of the bar-shaped hole, the contact switch 34 is in contact with the connecting device 2, which means that the connecting device 2 is in contact with the top of the bar-shaped hole 111, that is, the whole hoisting device is in the hoisting position, and the hoisting device is kept in the suction position at this time. If the contact switch 34 is not in contact with the connecting device 2, it means that the connecting device 2 is not in contact with the top of the strip hole 111, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com