Industrial process soft measurement modeling method based on cooperative training partial least squares model

A partial least squares, collaborative training technology, applied in instruments, adaptive control, control/regulation systems, etc., can solve the problems that the model prediction accuracy cannot reach effective accuracy, and the dominant variables are difficult to detect and ignore. Facilitate automated implementation, enhanced understanding and operational confidence, and improved forecasting effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

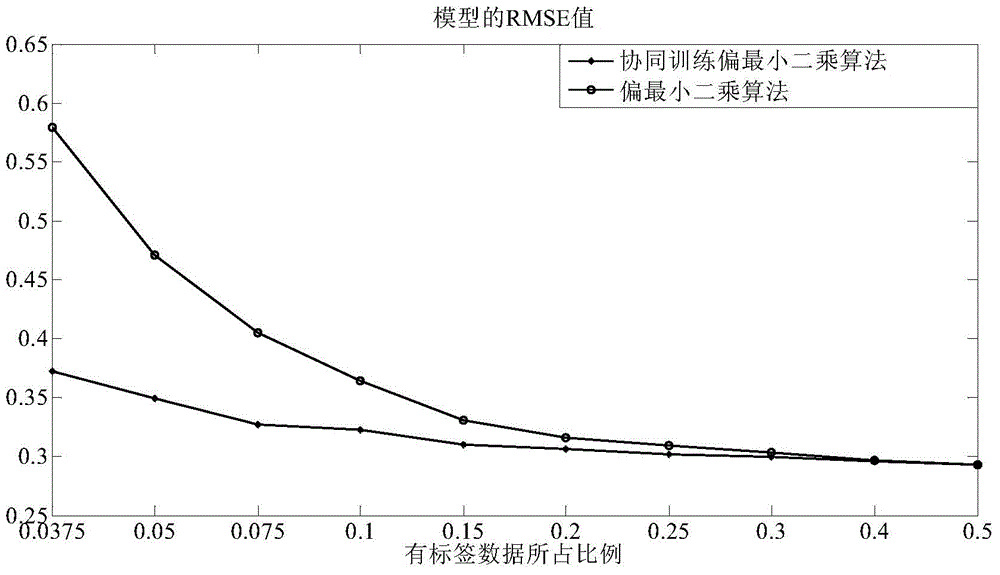

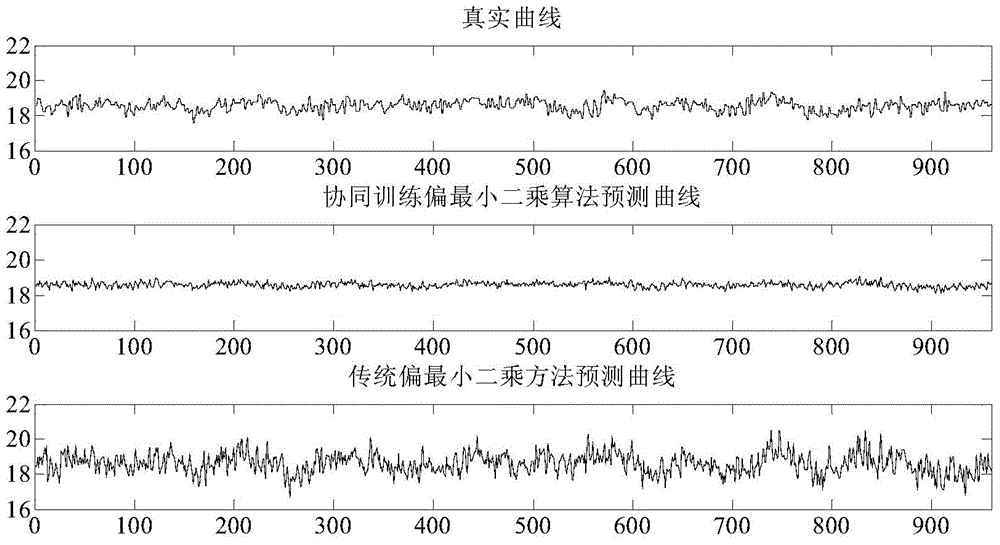

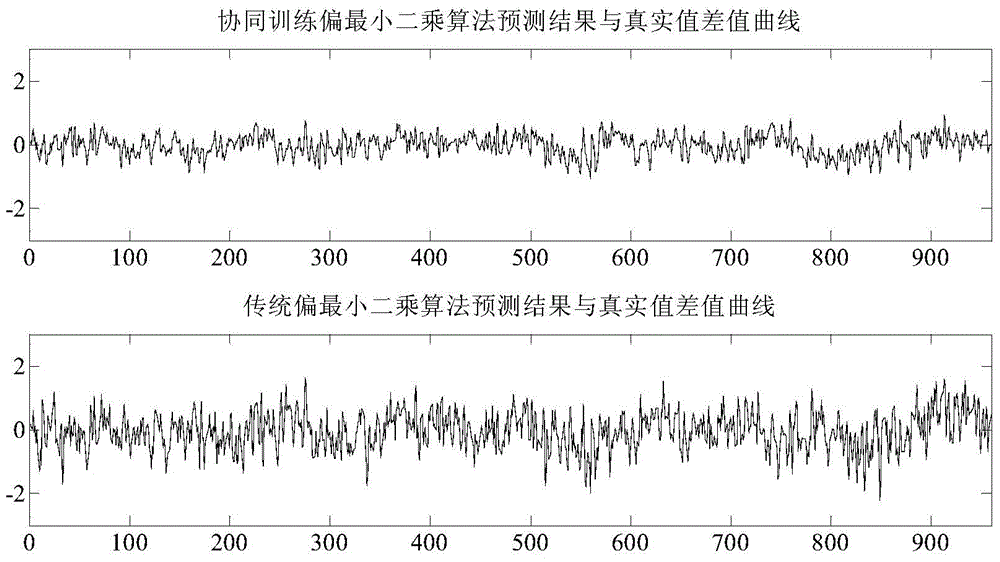

[0019] The present invention is aimed at the soft sensor modeling problem in the case of less training data in the industrial process. Firstly, the distributed control system is used to collect labeled and unlabeled data, and the labeled data is used to establish two initial models with certain differences, and then On the basis of the initial model, through continuous iterative cycles, the unlabeled data with the highest confidence is gradually converted into labeled data and added to the training set, gradually expanding the number of samples in the training set, and finally achieving the effect of improving the accuracy of the model . The invention not only improves the prediction effect of the soft sensor model of the industrial process, enhances the process operator's grasp of the process state, makes the industrial production safer, and the product quality is more stable; The dependence of knowledge is more conducive to the implementation of automation in industrial proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com