Control method of penicillin production process based on collaborative training lwpls

A collaborative training and production process technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as limiting prediction effect, ignoring unlabeled data, and wasting unlabeled data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

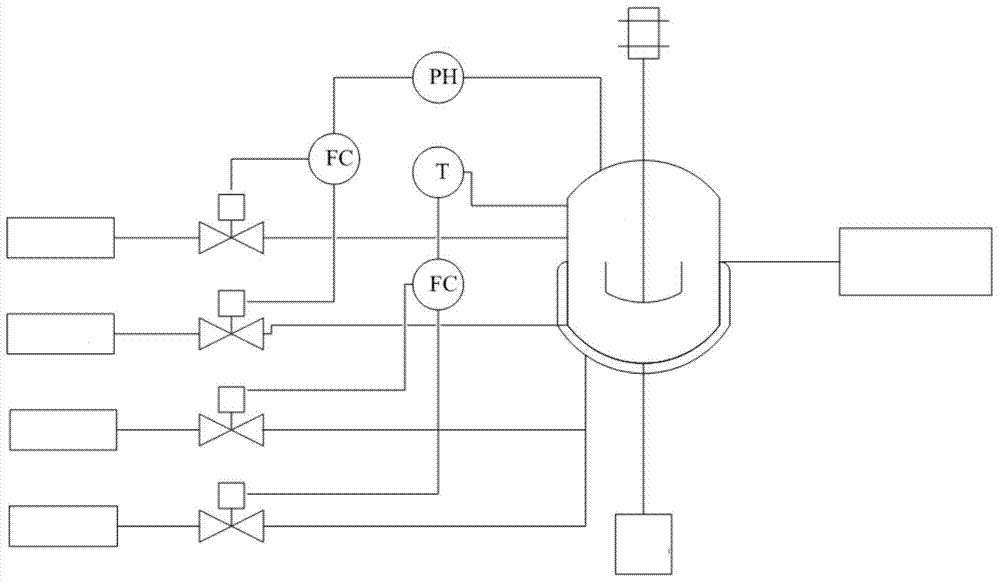

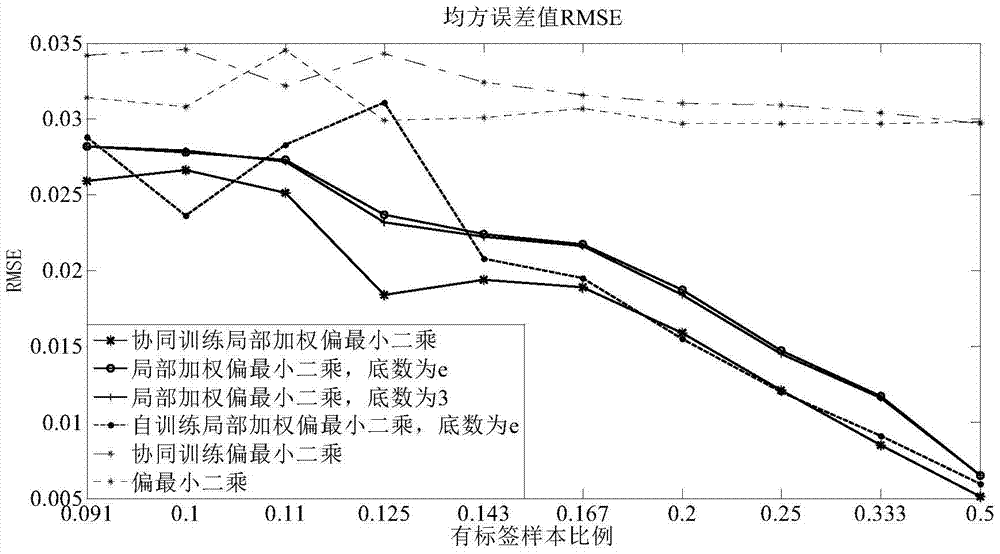

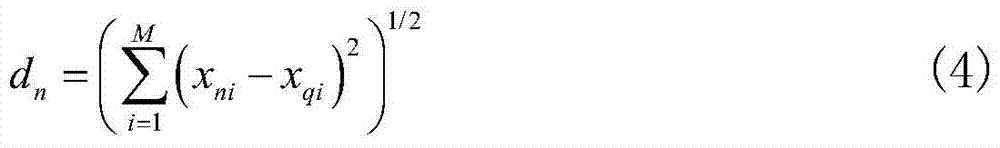

[0050] The present invention is a locally weighted partial least squares soft sensor modeling method based on a collaborative training algorithm. The method aims at the soft sensor modeling problem in the penicillin production process. Labeled data of variable information and unlabeled data containing only auxiliary variables, and then use the labeled data to establish two initial models with considerable differences, and then use unlabeled data on the basis of the initial model to train the two models The set is iteratively updated. When a certain number of iterations or termination conditions are reached, the update of the model is stopped, and a new model is established using the final training data to realize the soft sensor modeling of the penicillin production process. Store the model parameters in the database for later use.

[0051] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com