Electrical smelting furnace for magnesia fault monitoring method based on multi-manifold semi-supervised local-overall situation

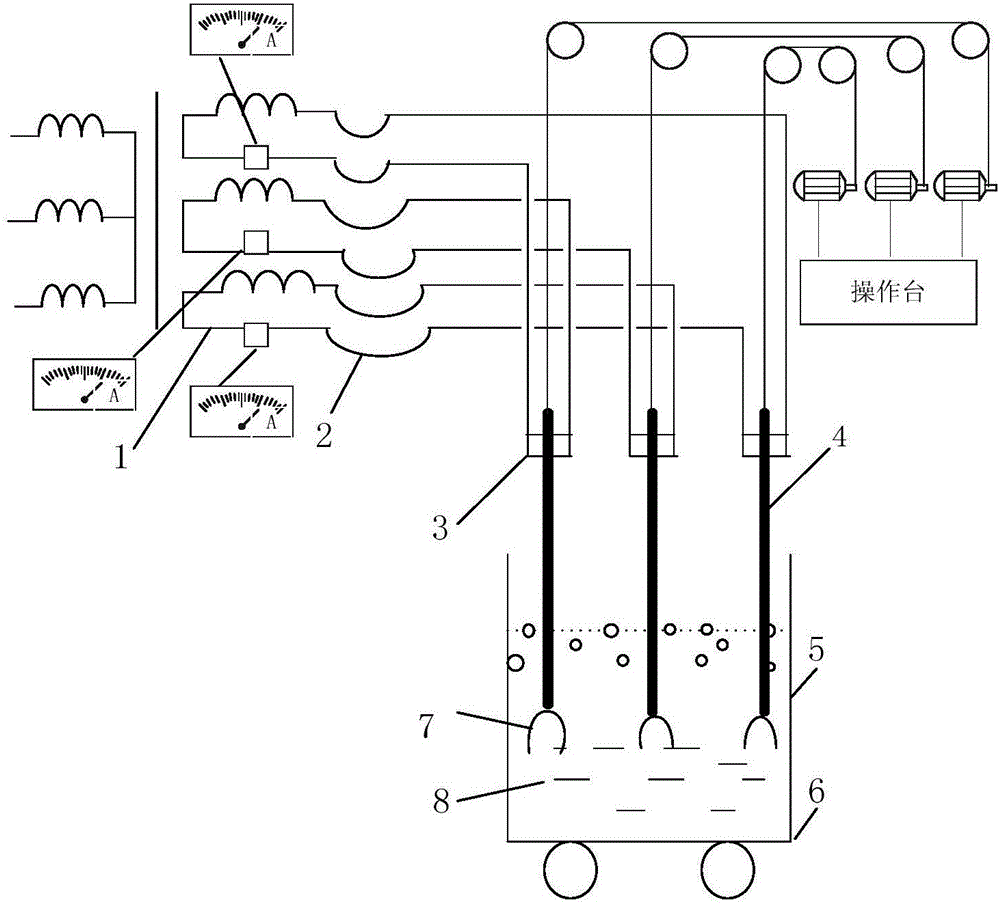

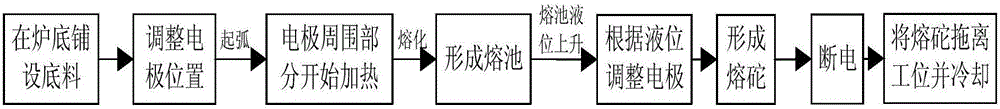

A technology for fused magnesia furnace and fault monitoring, applied in furnaces, charge materials, crucible furnaces, etc., can solve problems such as life-threatening, furnace leakage accidents, affecting product output and quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

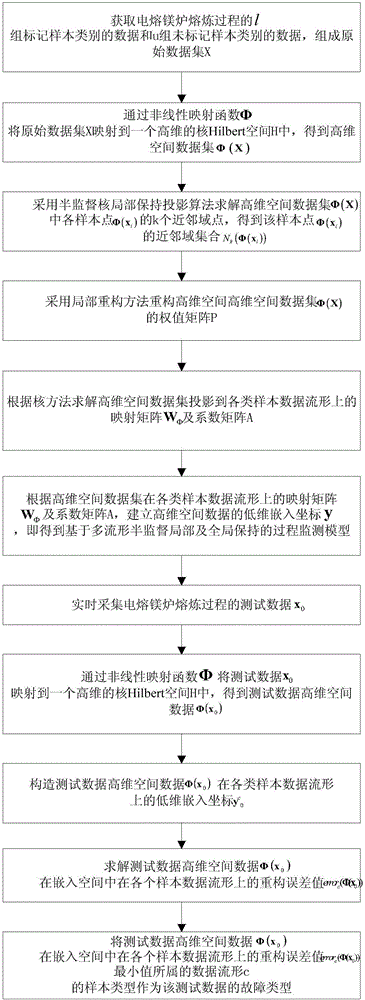

[0055] A multi-manifold semi-supervised local-global fault monitoring method for fused magnesium furnaces, such as image 3 shown, including the following steps:

[0056] Step 1: Obtain the data of group l marked sample categories and the data of group u unlabeled sample categories in the smelting process of the electric fused magnesium furnace, and form the original data set X=(X L , X U )∈R m×n , where X L =[x 1 , x 2 ,...,x l ],X U =[x l+1 , x l+2 ,...,x l+u ], l+u=n, for labeled data, is unlabeled data, and m is the data dimension.

[0057] In this embodiment, the original data are 13 process variables such as input voltage value, three-phase current value, furnace temperature value, electrode relative position, gas flow rate, pressure, weight, etc. During the production process, when the current setting value remains un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com