Vertical double-side-blowing smelting furnace

A smelting furnace and vertical technology, which is applied in the field of vertical double-side blowing smelting furnaces, can solve problems such as affecting the antegrade flow of the smelting furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

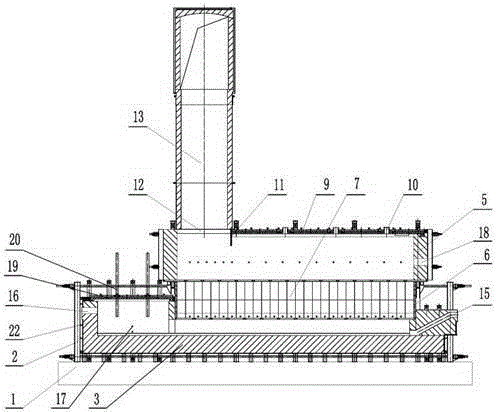

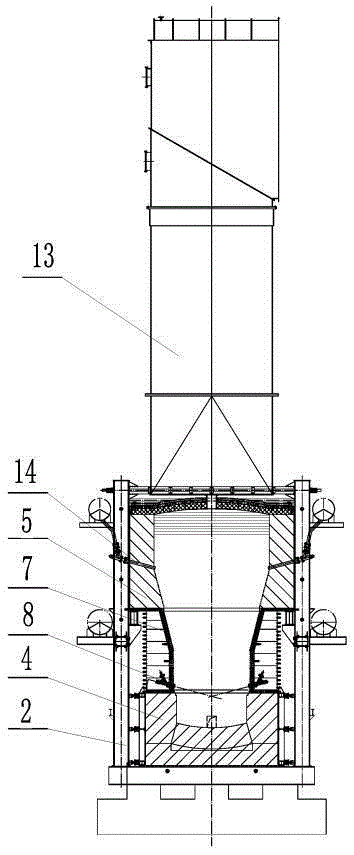

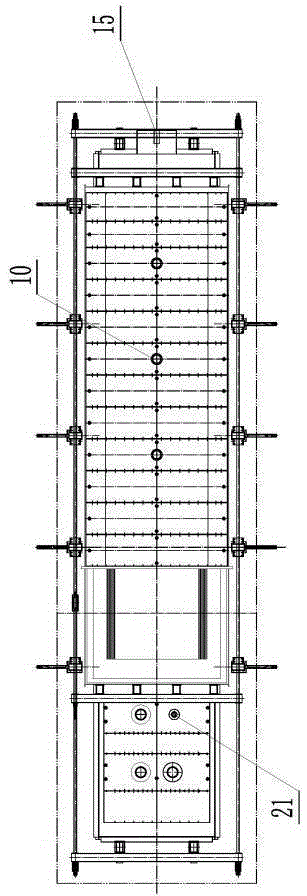

[0016] see Figure 1-Figure 3 The smelting furnace of the present invention includes a furnace foundation 1, an external steel structure of the furnace body 2, a refractory furnace bottom 3, a furnace wall brickwork 4 in the lower section of the reaction zone of the smelting furnace, a side wall in the upper part of the smelting zone, and a refractory material 5 in the end wall. Copper water jacket on the end wall in the middle section of the reaction zone 6, copper water jacket on the side wall in the middle section of the smelting reaction zone 7, copper water jacket on the side wall of the smelting reaction zone for ventilating holes 8, the furnace roof 9 located above the smelting reaction zone, set on the furnace roof The feeding hole 10 of the smelting reaction zone, the slag blocking screen water jacket 11 at the top of the smelting reaction zone, the smoke outlet 12 at the furnace top of the smelting reaction zone, the refractory-lined flue 13, the secondary air supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com