Multi-furnace combined type fusion casting equipment and technology for producing high-cleanness magnesium or magnesium alloy

A high-cleanliness, magnesium alloy technology, applied in the field of metal smelting, can solve the problems of similar melt density difference, smoke environmental pollution, and damage to the surface flux protective layer. The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

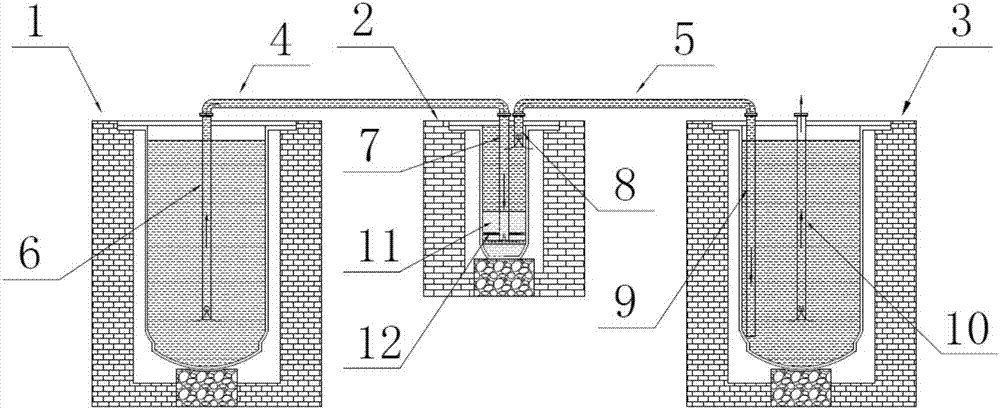

Image

Examples

Embodiment 1

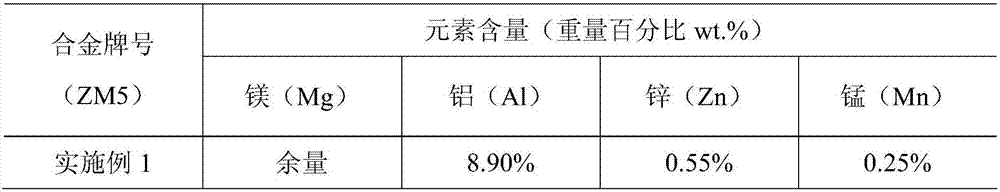

[0032] The magnesium alloy composition of the present embodiment is as shown in table 1:

[0033] Table 1

[0034]

[0035] Using the multi-furnace combined melting and casting equipment and process of the present invention, the magnesium alloy of Example 1 with high cleanliness is obtained, and its preparation process includes the following steps:

[0036] (1) Preheat the raw materials to 120°C after cleaning;

[0037] (2) Set the temperature of the melting crucible to 700°C and start to heat up. When the melting crucible is dark red, sprinkle RJ-2 flux not exceeding 1% of the mass of pure magnesium on the bottom of the crucible, and add magnesium ingots through the feeding hole. Cover it with a layer of RJ-2 flux not exceeding 1% of the mass of pure magnesium, cover and melt; after the pure magnesium ingot is melted, add other alloy ingredients, stir evenly, and take component samples for inspection.

[0038] (3) After the melting crucible reaches the set temperature, s...

Embodiment 2

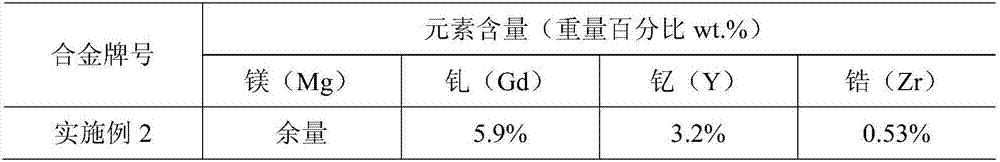

[0043] The magnesium alloy composition of the present embodiment is as shown in table 2:

[0044] Table 2

[0045]

[0046] Using the multi-furnace combined melting and casting process and equipment of the present invention, the magnesium alloy of Example 2 with high cleanliness is obtained, and its preparation process includes the following steps:

[0047] (1) The raw materials are cleaned and preheated to 180°C;

[0048] (2) Set the temperature of the crucible in the melting furnace to 780°C and start to heat up. When the crucible in the melting furnace is dark red, sprinkle RJ-6 flux not exceeding 1% of the mass of pure magnesium at the bottom of the crucible, and add magnesium ingots through the feeding hole. , Cover the magnesium ingot with a layer of RJ-6 flux not exceeding 1% of the mass of pure magnesium, cover and melt; after the pure magnesium ingot is melted, add other alloy ingredients, stir evenly, and take a component sample for inspection.

[0049] (3) Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com