Device for microwave sintering of ceramic particles by rotary garbage incineration fly ash and operation method

A technology of waste incineration fly ash and microwave sintering, applied in the field of waste incineration fly ash treatment, can solve the problems of long sintering time period, unstable product quality, low sintering recovery rate, etc., achieve full energy utilization, promote industrialization process, The effect of large heat radiation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

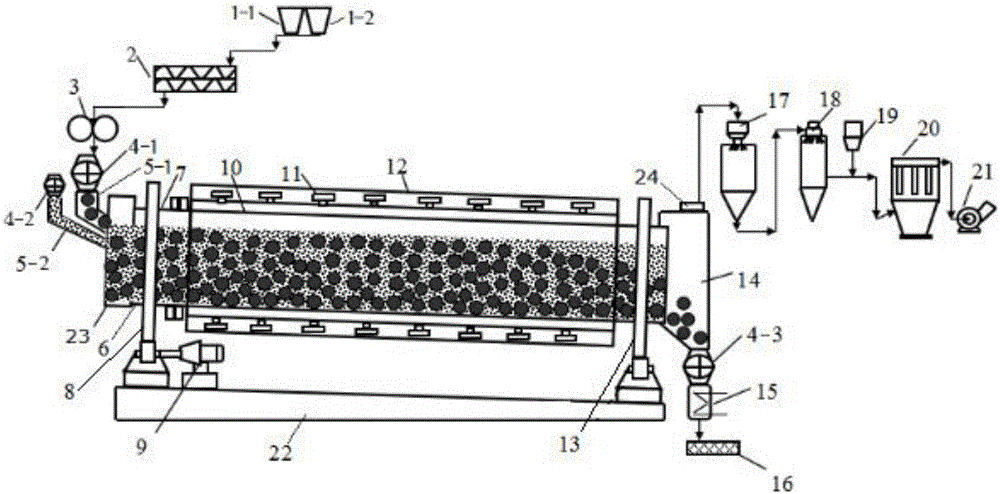

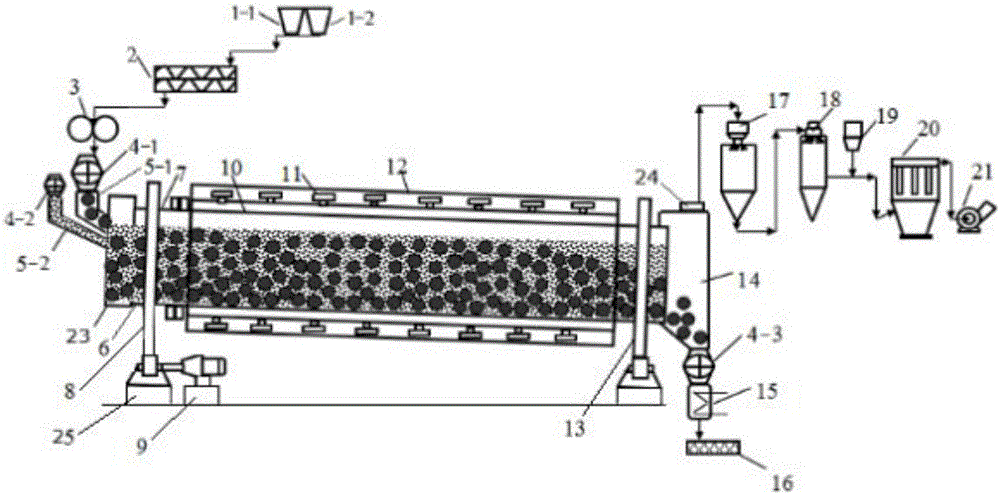

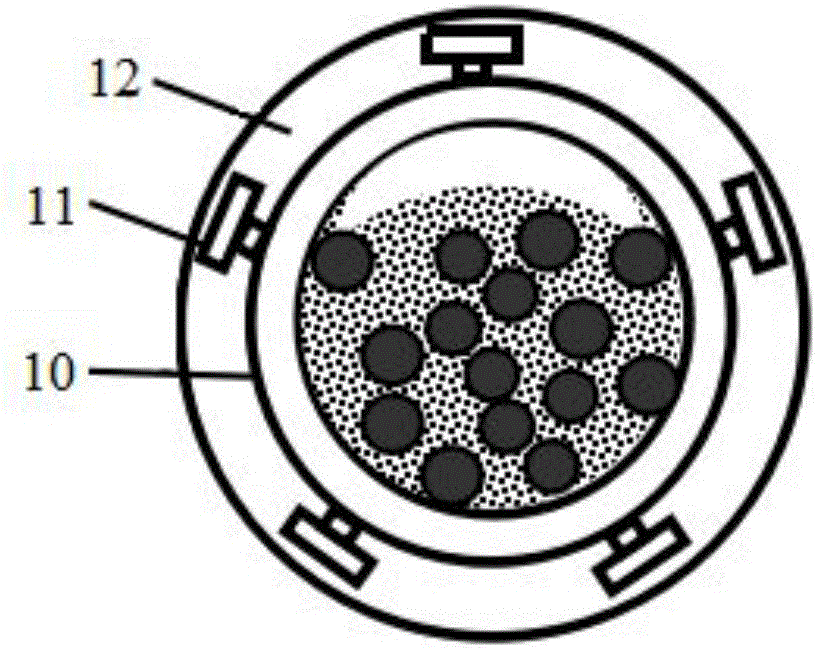

[0038] The present invention is described in further detail below in conjunction with the accompanying drawings and specific embodiments:

[0039] A rotary type waste incineration fly ash microwave sintering ceramsite device, comprising a first hopper, a second hopper, a stirring device, a molding machine, a first feeding port, a second feeding port, a rotary reaction furnace, a microwave heating device, Front bracket, rear bracket, flue gas outlet, cooling device, vibrating screen, water cooling device, deacidification tower, activated carbon injection device, bag filter and induced draft fan; of which:

[0040]The first hopper and the second hopper are respectively connected to the stirring device, and the medical waste incineration fly ash and pyrite slag are added to the stirring device through the two hoppers, and the stirring device is used to mix evenly;

[0041] The stirring device is connected to the molding machine, and the feeding device is used to control the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com