Device for producing iron and aluminum composite material

A technology of composite materials and iron elements, applied in the field of metals, can solve problems such as lack, and achieve the effects of novel design, convenient use, and simple structure

Inactive Publication Date: 2018-12-28

KUNSHAN JIANJIN IND DESIGN

View PDF7 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there are many types of ferroalloy products, but there is still a lack of such production equipment on the market. In view of this, it is necessary to study a device for composite materials of iron and aluminum elements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

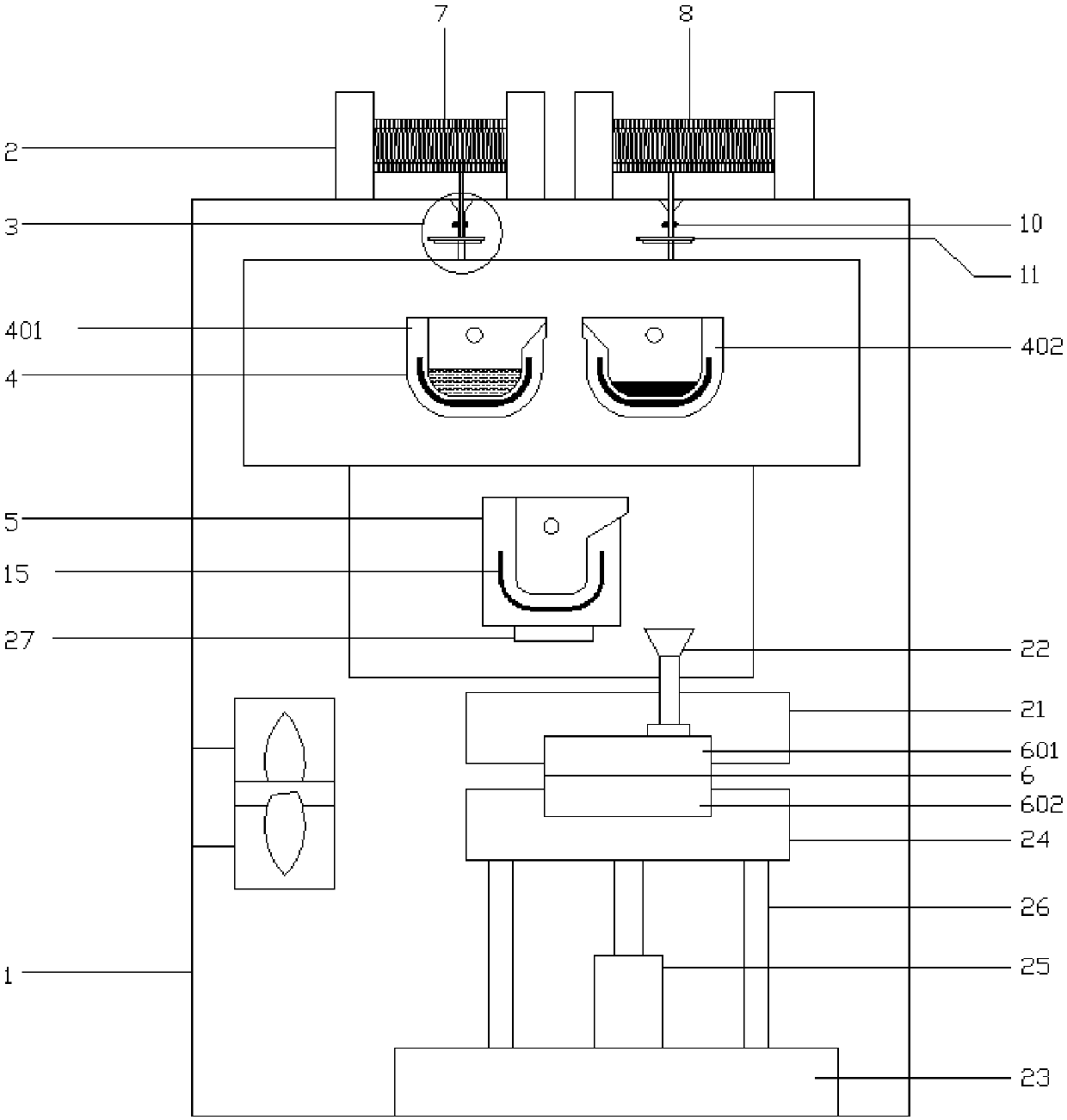

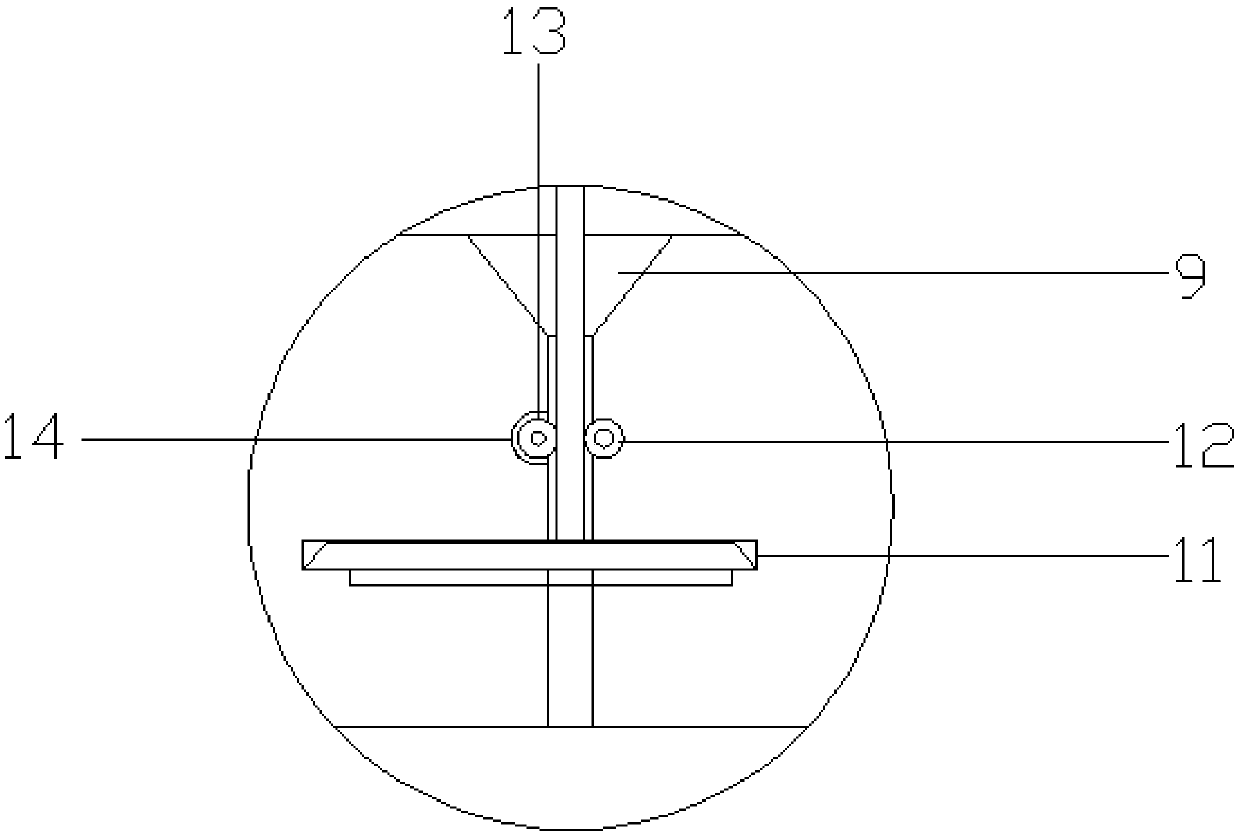

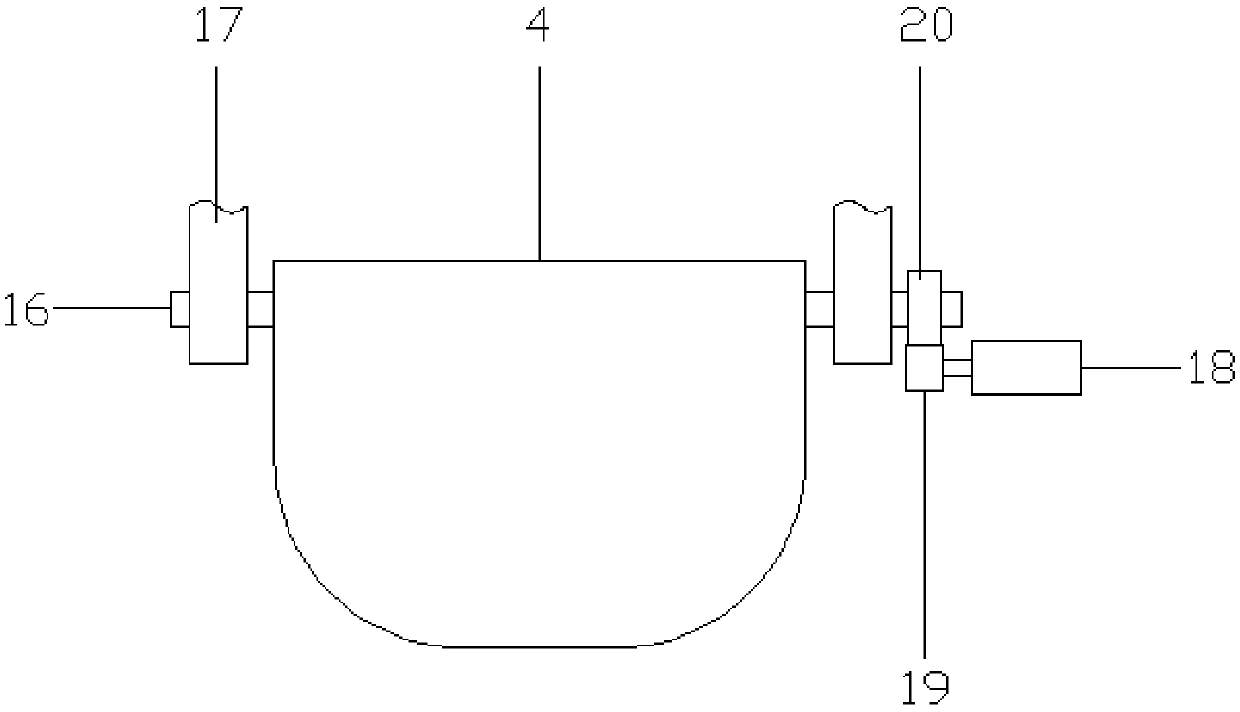

The invention discloses a device for producing iron and aluminum composite materials. The device comprises a device body, wherein the device body comprises raw material rolls, feed devices, a high-temperature melting furnace, a high-temperature rabbling furnace and a mold from top to bottom sequentially; the raw material rolls are wound with an iron wire and an aluminum wire which are connected with the feed devices; the feed devices comprise feed holes connected with the iron wire and the aluminum wire as well as drive devices and shear devices arranged at the feed holes; the iron wire and the aluminum wire are melted respectively by the high-temperature melting furnace, poured into the high-temperature rabbling furnace, rabbled by the high-temperature rabbling furnace and injected into the mold, and the iron composite materials are molded. The iron composite materials with different composition and different proportions can be produced by the device and used for research, and the optimal iron composite material can be selected.

Description

technical field The invention relates to the field of metals, in particular to a device made of iron and aluminum composite materials. Background technique Iron-aluminum alloy is composed of iron and aluminum (about 6%~16%) as the main elements. It has high resistivity, low density, high hardness, good wear resistance, good vibration and impact resistance, so iron is used Devices made of aluminum alloy have low eddy current loss and light weight. However, when the aluminum content exceeds 10%, the iron-aluminum alloy becomes brittle and its plasticity decreases, which brings difficulties to processing. The saturation magnetic induction of the alloy decreases with the increase of aluminum content. Commonly used iron-aluminum alloys can be cold-rolled or hot-rolled strips, with a thickness of 0.1~0.5mm. Its main features are high resistivity and hardness, low density (6.5~7.2g / mm3), good anti-vibration and impact resistance, and its magnetic properties are not as sensitive...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22C9/20B22D33/04C22C33/04C22C38/06F27B19/04

CPCB22C9/20B22D33/04C22C33/04C22C38/06F27B19/04F27M2001/012F27M2001/02

Inventor 林建斌

Owner KUNSHAN JIANJIN IND DESIGN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com