Sintered brick made from watercourse sludge and peat, sintering and waste gas purifying system, and sintering and waste gas purifying method

A waste gas purification system and river silt technology, applied in the firing and waste gas purification system, and the field of sintered bricks, can solve the problems of backward waste gas treatment technology and inability to guarantee up-to-standard discharge, and achieve the goal of increasing SCR denitrification process, easy landing, and energy saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

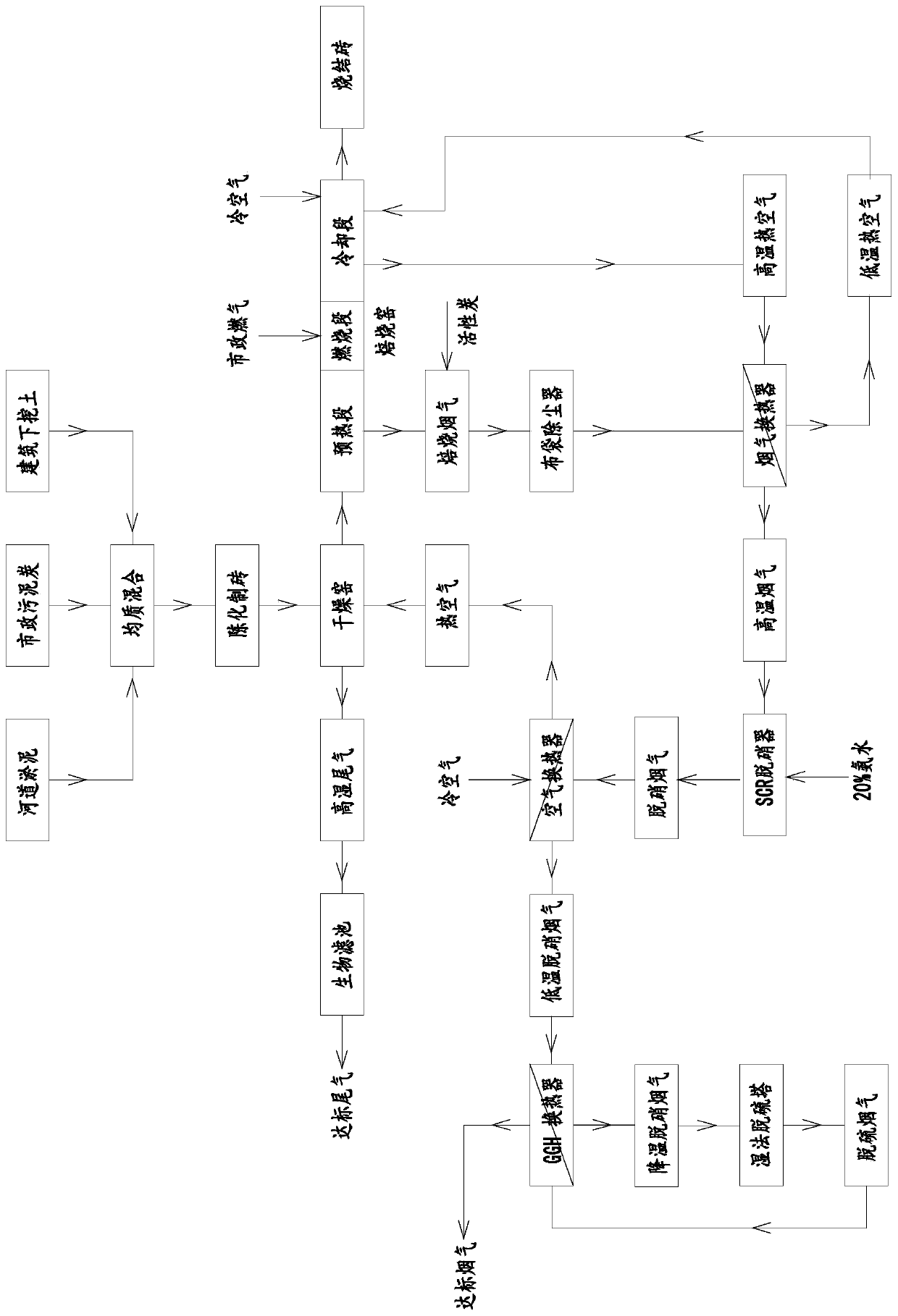

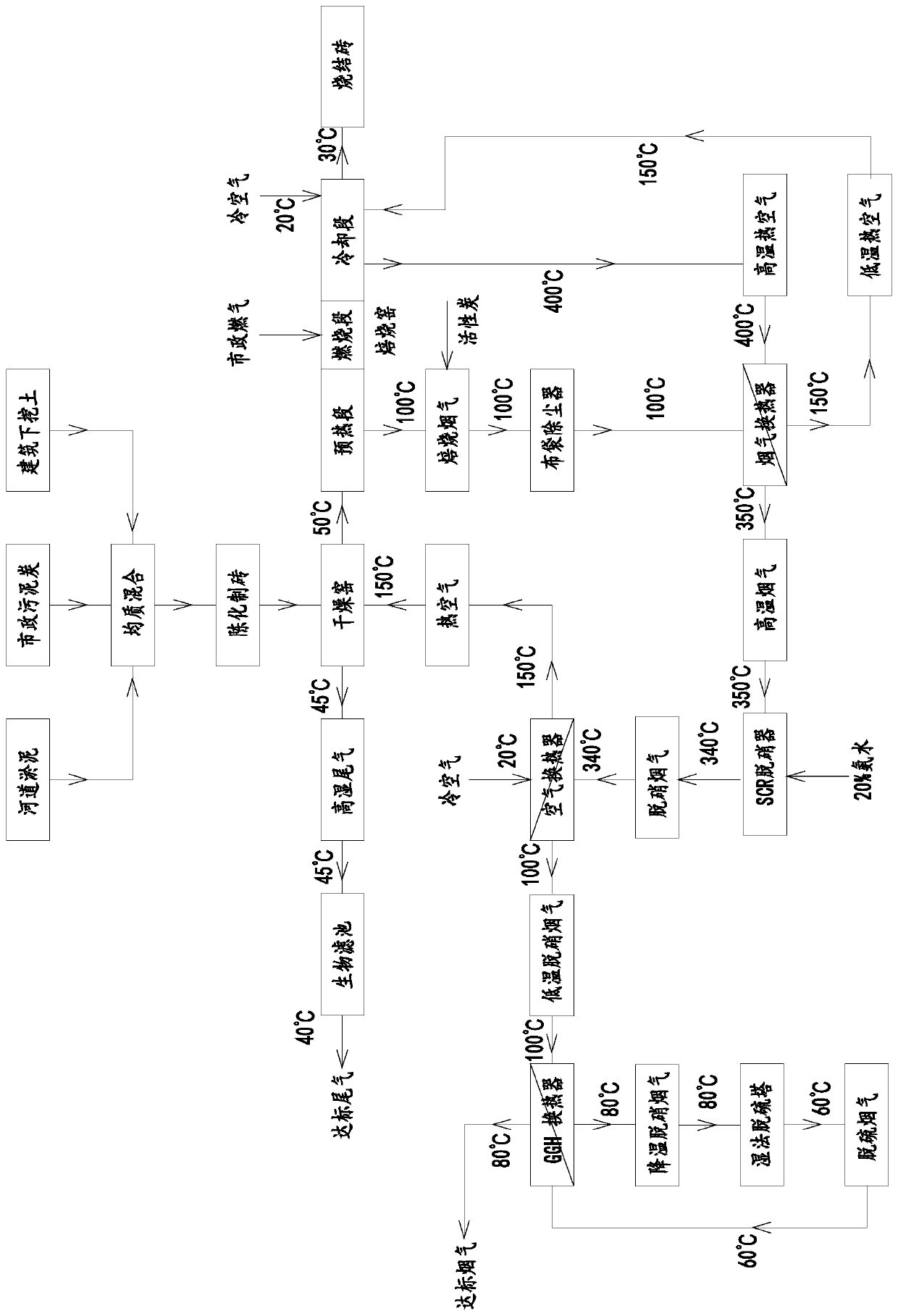

[0047] The firing of the sintered brick prepared by river silt and sludge charcoal of the present invention and the embodiment of waste gas purification system are as follows figure 1 , figure 2 As shown, the system includes a drying kiln, a drying tail gas purification device, a roasting kiln and a roasting flue gas purification device. The drying kiln is respectively connected with the drying tail gas purification device and the roasting kiln. The kiln is roasted to form sintered bricks; the drying tail gas purification device is used to purify the high-humidity tail gas discharged from the drying kiln; the roasting flue gas purification device is connected with the roasting kiln to purify the waste gas discharged from the roasting kiln.

[0048] In this embodiment, the dry tail gas purification device is a biological filter, and the biological filter is connected to the pipeline for discharging the purified tail gas; the temperature of the high-humidity tail gas is 40-45°C...

Embodiment 2

[0073] The structure and temperature control points of embodiment 2 of the firing of sintered bricks prepared by river silt and sludge charcoal and the waste gas purification system of the present invention are the same as embodiment 1, and the method steps are also the same, and the ingredients are different. The specific process is as follows:

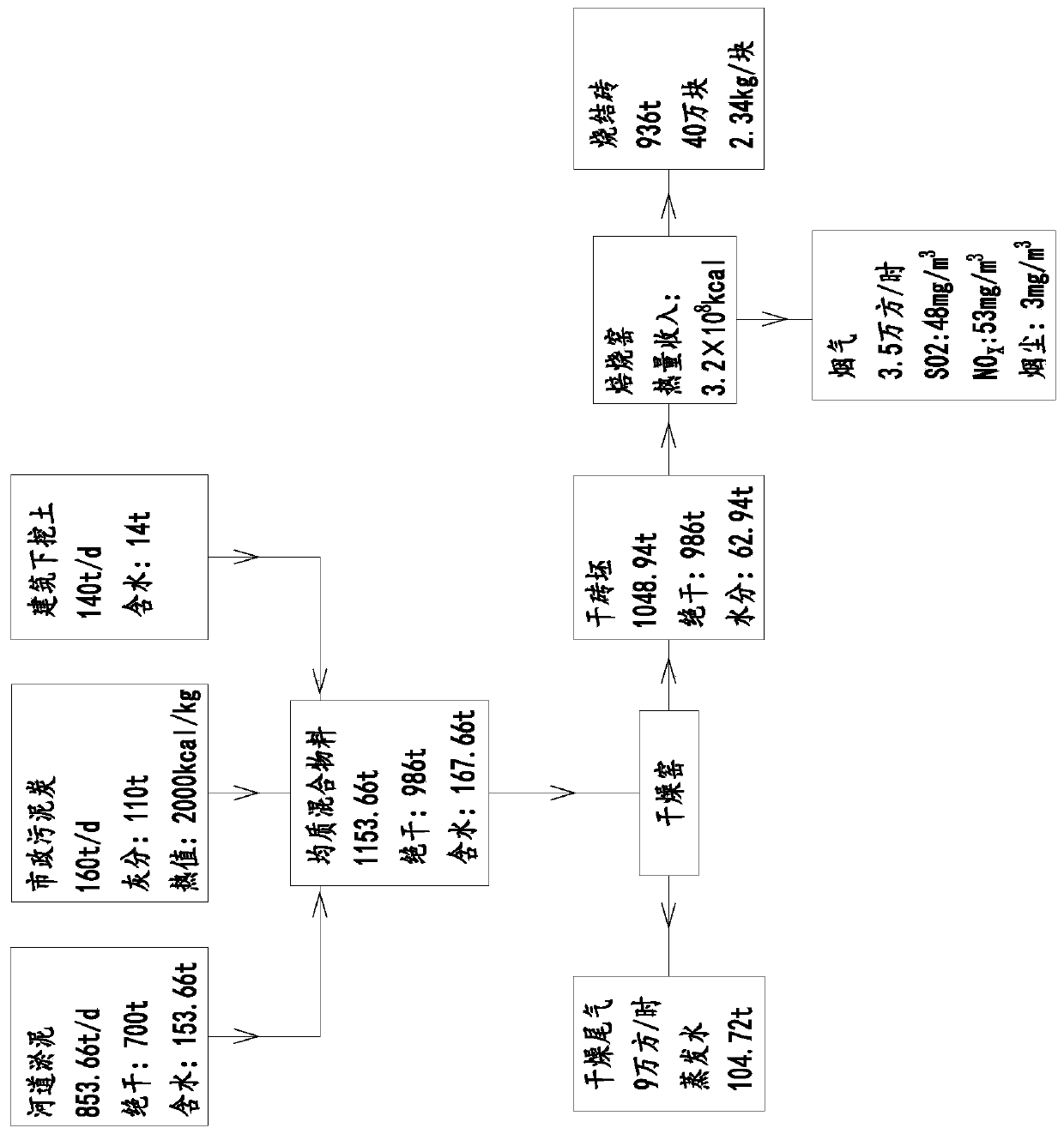

[0074] After drying 1000t of river sludge with a water content of 30%, 853.66t of semi-dry river sludge with a water content of 18%, 200t of municipal sludge charcoal with an ash content of 75%, and 100t of soil excavated under a building with a water content of 10% were evenly mixed to obtain a water content 1153.66t of 14.2% mud, aged for 2 days, pressed and cut into bricks, the moisture content of the bricks is 14.2%, the ingredients and weight ratio in the bricks are calculated on a dry basis: river silt 70.7%; Excavated soil is 9.1%; municipal sludge charcoal is 20.2%, and the brick embryos are fired to form sintered bricks.

[...

Embodiment 3

[0095] The structure and temperature control points of Embodiment 3 of the firing of sintered bricks prepared by river silt and sludge charcoal and the exhaust gas purification system of the present invention are the same as Embodiment 1, and the method steps are also the same, and the ingredients are different. The specific process is as follows:

[0096] After drying 1000t of river sludge with a water content of 30%, 853.66t of semi-dry river sludge with a water content of 18%, 200t of municipal sludge charcoal with an ash content of 80%, and excavated soil under construction with a water content of 10% were uniformly mixed to obtain a water content 1153.66t of 14.2% mud, aged for 2 days, pressed and cut into bricks, the moisture content of the bricks is 14.2%, the ingredients and weight ratio in the bricks are calculated on a dry basis: river silt 70.7%; Excavated soil is 9.1%; municipal sludge charcoal is 20.2%, and the brick embryos are fired to form sintered bricks.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com