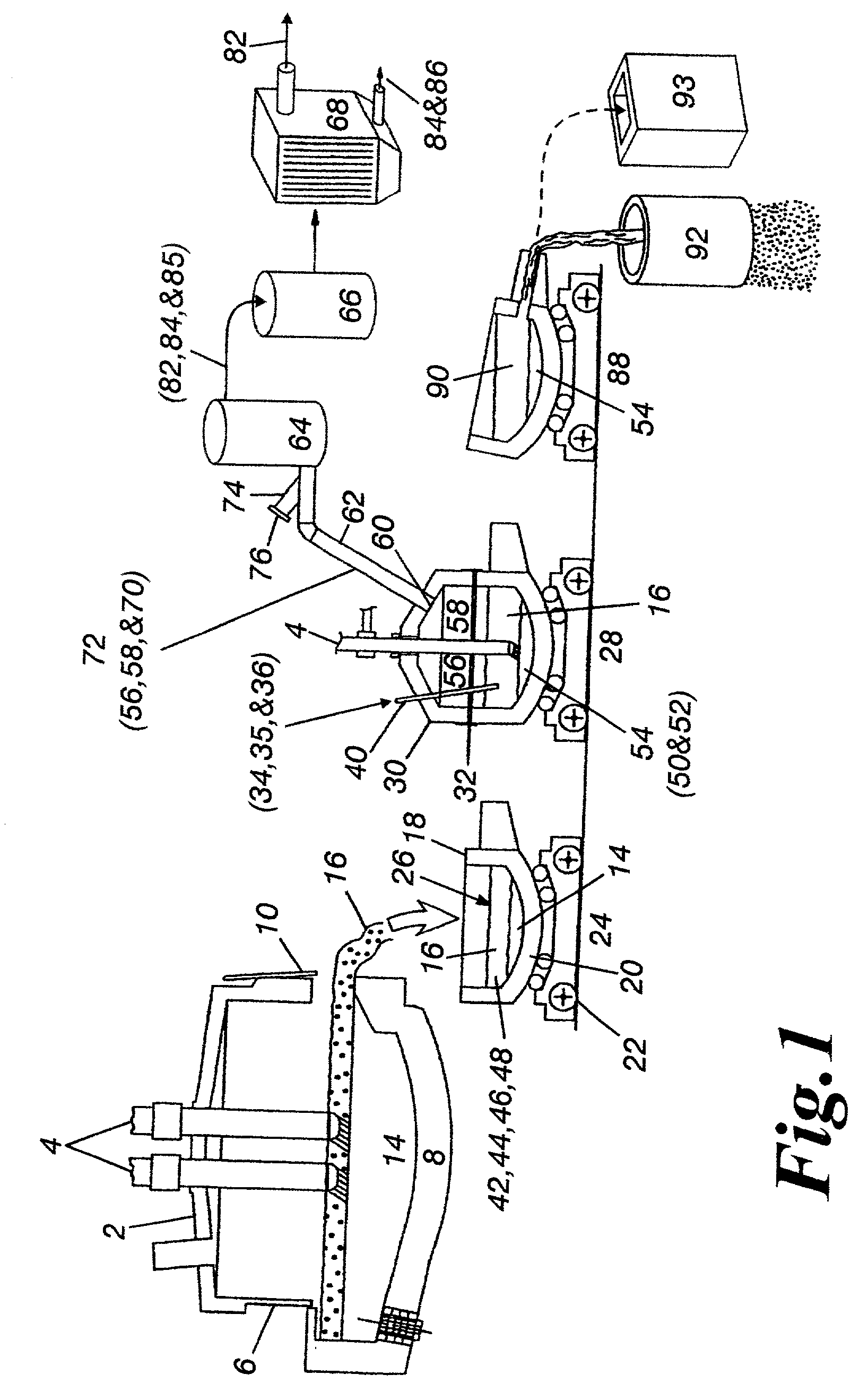

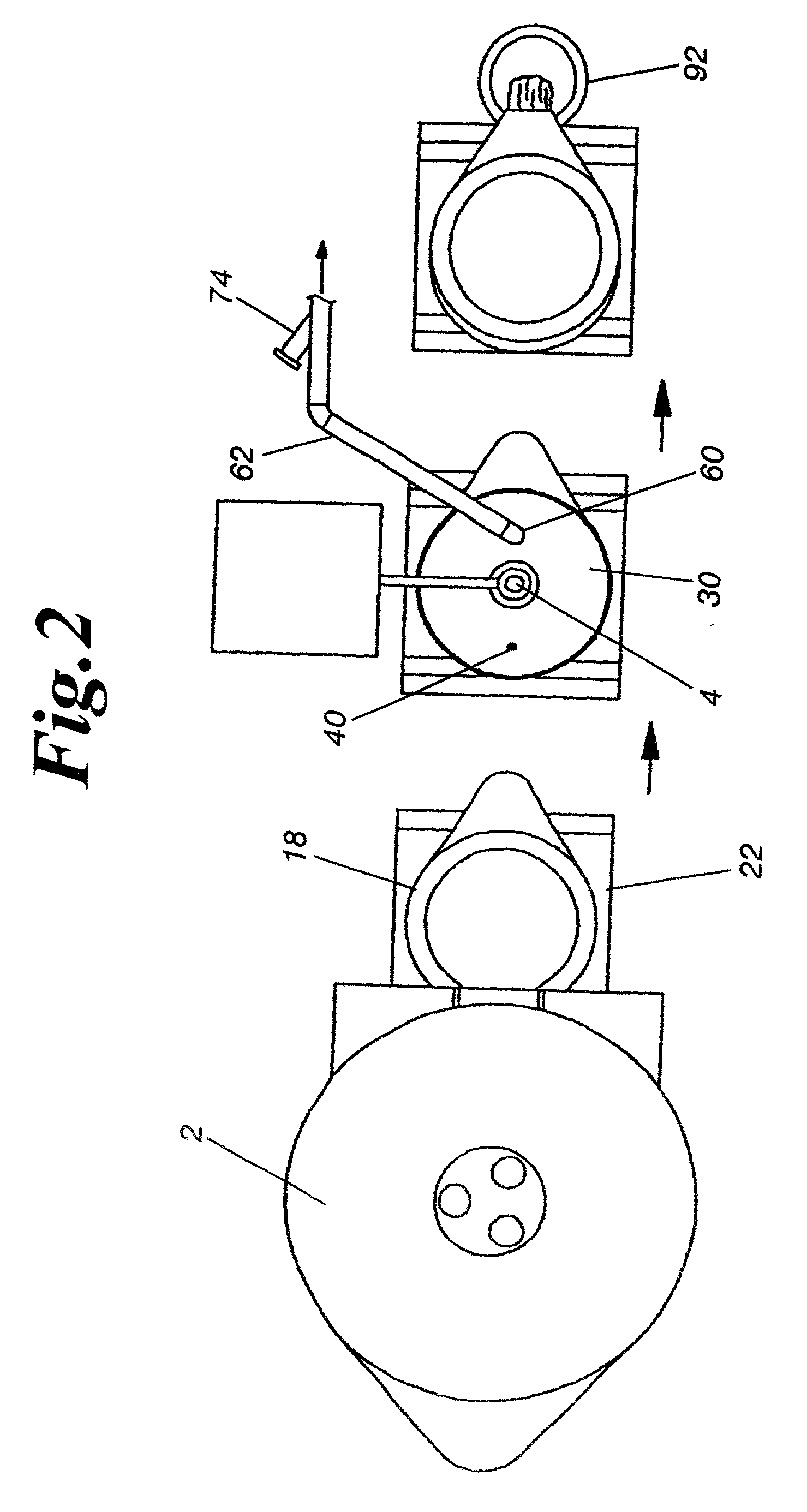

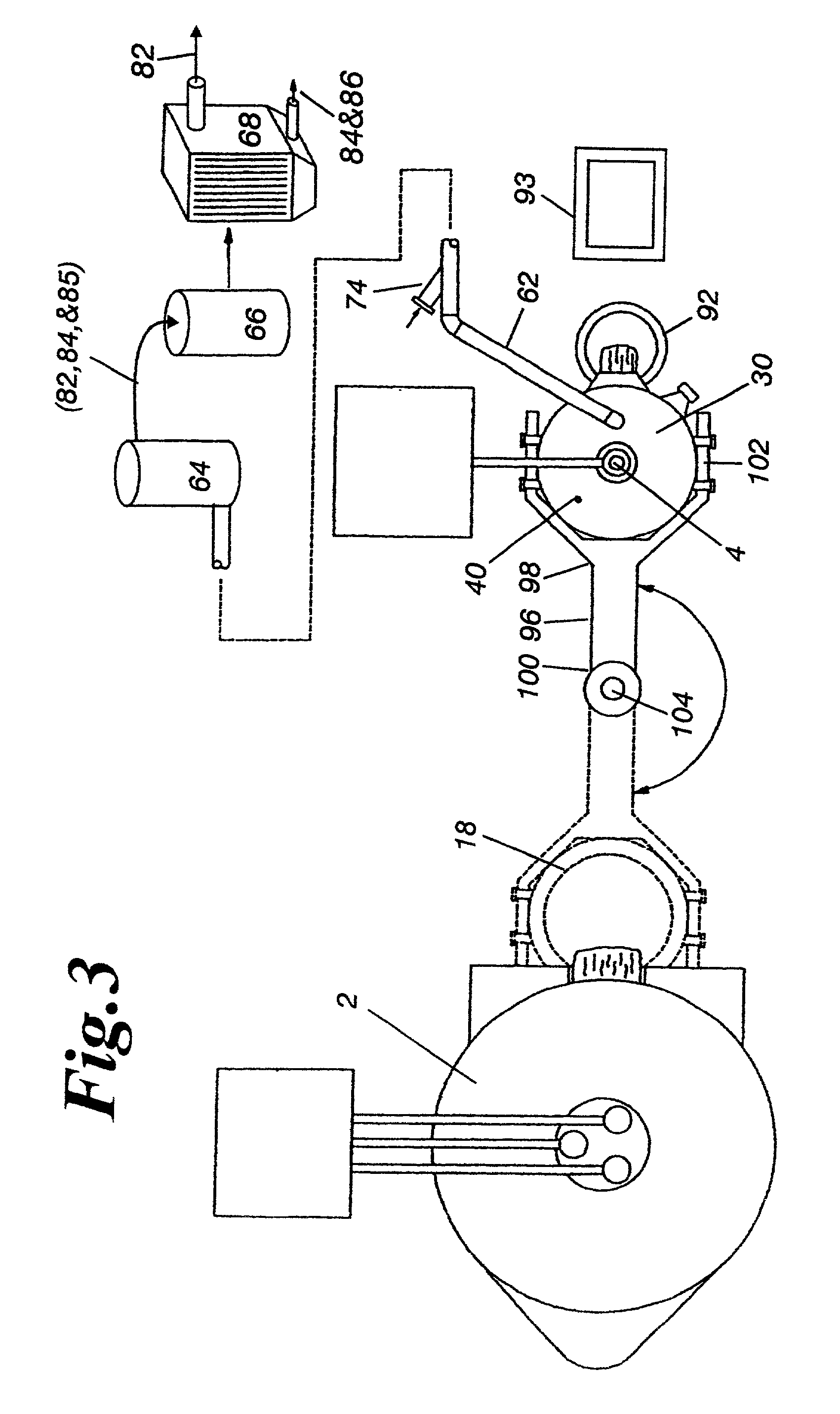

Method and apparatus for recovering metal values from liquid slag and baghouse dust of an electric arc furnace

a technology of liquid slag and baghouse dust, which is applied in the direction of waste heat treatment, incrustation removal devices, charges, etc., can solve the problems of inevitably trapped residual amounts of valuable metal, high cost of disposal, and harm to the environment, and achieve the effect of lowering the cost of treatment and disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0041] The following example shows the amount of metallic components recoverable from EAF slag corresponding to one tonne of tapped molten steel. The silicon dioxide in this Example is input to the lower shell portion of the treatment vessel at room temperature. Component temperatures and electrical energy input is also shown.

3 Inputs 100 kg Untreated Slag (1400.degree. C.) 20.2 kg SiO.sub.2 (25.degree. C.) 11 kg dust (25.degree. C.) 6.44 kg coal (25.degree. C.) 39 kWh Outputs 107 kg Treated Slag (1400.degree. C.) CaO 38.8% SiO.sub.2 32.3% MgO 12.9% Al.sub.2O.sub.3 9.5% MnO 5.1% FeO 0.9% P.sub.2O.sub.3 0.41% S 0.032% 15.3 kg Molten Metal (1400.degree. C.) Mn 7.4% C 4.5% Si 0.29% Cu 0.15% Ni 0.014% P 39 ppm S 16 ppm 7.85 NM.sup.3 Gas (1400.degree. C.) CO 99.6% SO.sub.2 0.034% As 14 ppm 3.573 kg Vapor (1400.degree. C.) (metal in vapor phase) Zn 85.6% (3.06 kg) Pb 10.3% (0.37 kg) Na 3.9% (0.14 kg) Cd 0.3% (0.01 kg)

[0042] If room temperature slag is instead fed into the treatment vessel...

example 2

[0054] Coal-oxygen heating of slag is accomplished with an oxy-fuel burner. All figures are per tonne of tapped molten steel. The silicon dioxide in the present invention will be heated to 1200.degree. C., unlike the room temperature sand in this example.

4 Inputs 100 kg slag (1400.degree. C.) 18.4 kg SiO.sub.2 (25 .degree. C.) 11 kg dust (25.degree. C.) 42.1 kg coal (25.degree. C.) (partially for reduction; partially for heating) 25 Nm.sup.3 Outputs 108.6 kg Slag (1400.degree. C.) CaO 38.5% SiO.sub.2 32.0% MgO 12.7% Al.sub.2O.sub.3 10.3% MnO 5.1% FeO 0.9% P.sub.2O.sub.3 0.46% S 0.21% 15.3 kg Molten Metal (1400.degree. C.) Mn 7.3% C 4.5% Si 0.29% Cu 0.15% Ni 0.014% S 0.01% P 39 ppm 56.65 NM.sup.3 Gas (1400.degree. C.) CO 99.9% SO.sub.2 0.032% As 2 ppm 3.573 kg Vapor (1400.degree. C.) Zn 85.6% (3.06 kg) Pb 10.3% (0.37 kg) Cd 0.3% (0.01 kg) Na 3.9% (0.14 kg)

[0055] This shows that utilizing electric energy is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com