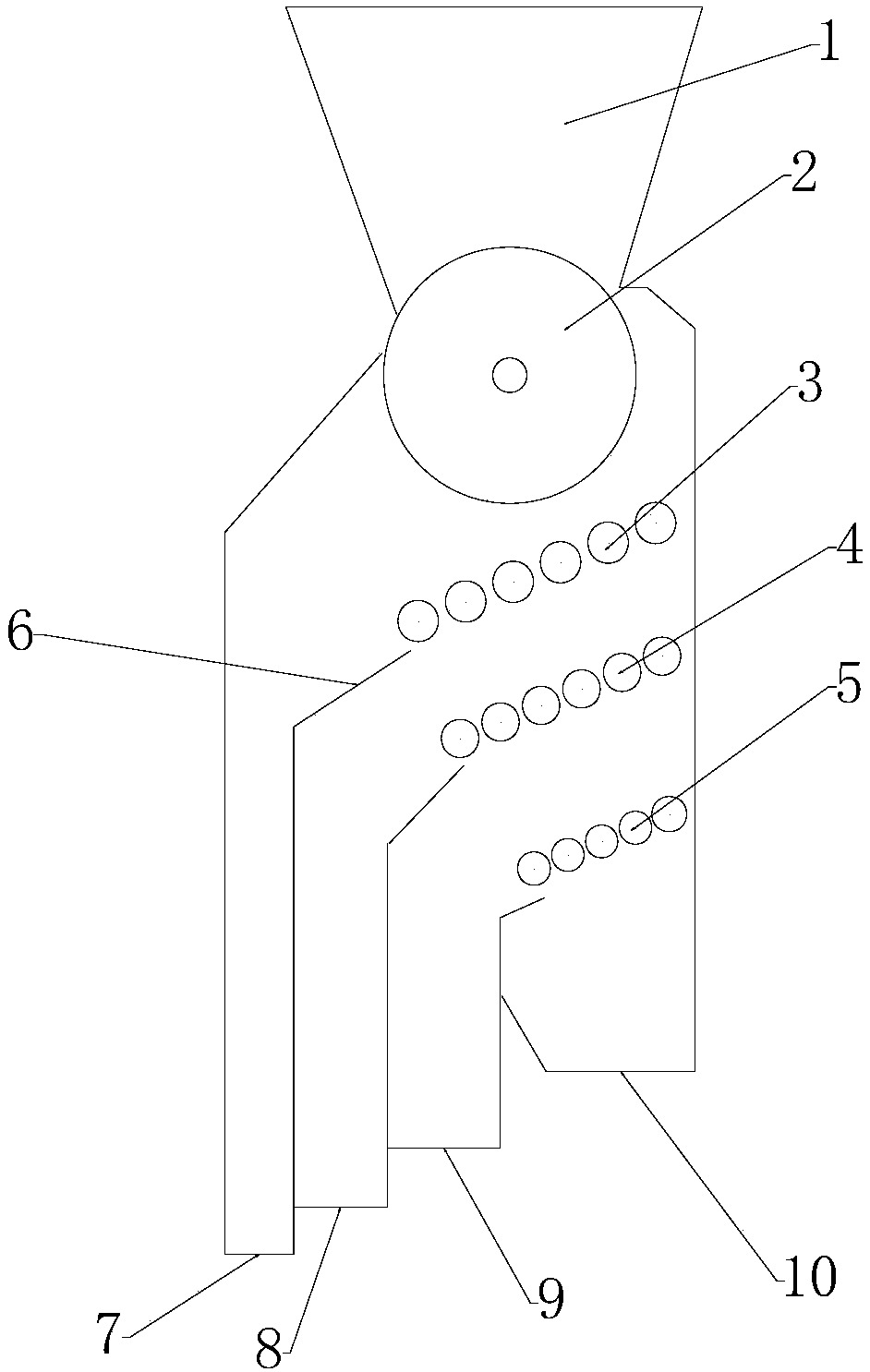

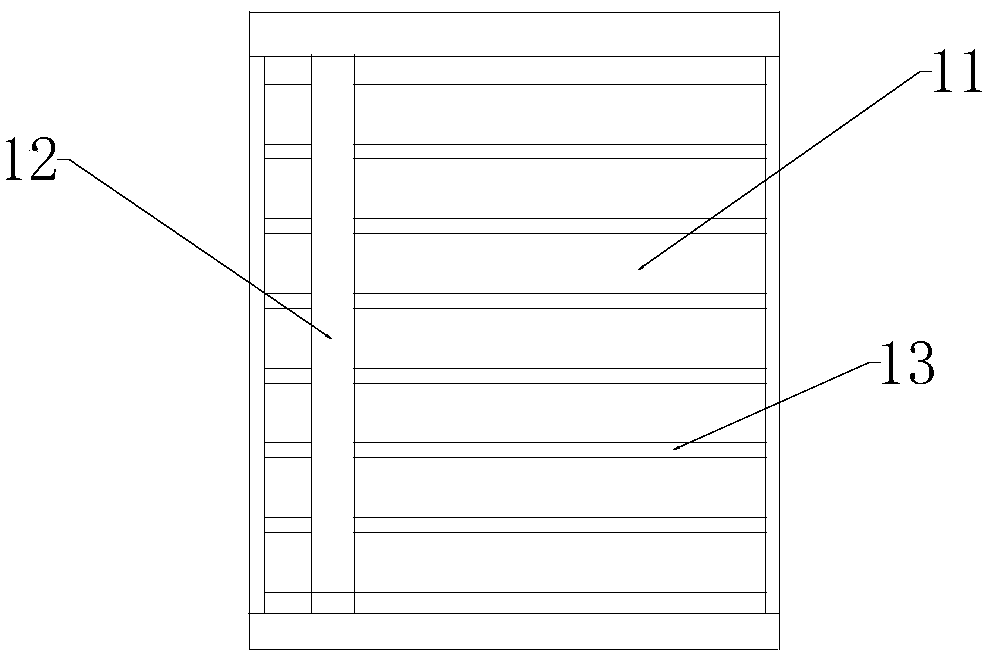

Sintered mixture preparation method, sintered mixture distribution apparatus and sintered mixture distribution method

A technology of sintering mixture and material distributing device, which is applied in the field of ironmaking production to achieve the effect of improving sintering utilization coefficient and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The mass percentages of raw iron ore powder, coke powder, returned ore, quicklime and limestone are: iron ore powder 70%, coke powder 4%, returned ore 12%, quicklime 5%, limestone 9%, and the alkalinity of the sintering mixture is 2.0. Coke powder with a particle size of less than 3mm accounts for 75%, with an average particle size of 1.8mm; limestone with a particle size of less than 3mm accounts for 80%, with an average particle size of 1.55mm.

[0032] For wetting the returned ore water, the mass fraction of the returned ore fetched water with a particle size of less than 3mm is 4.5%, and the mass fraction of the returned ore fetched water with a particle size of 3-5mm is 3.5%; The returned ore, coke powder with a particle size of 0-3mm, and limestone with a particle size of less than 3mm were added with water accounting for 85% of the total water addition, and the filling rate of the primary mixer was 14%. After mixing for 6 minutes in the primary mixer, the primary ...

Embodiment 2

[0038] The mass percentages of raw iron ore powder, coke powder, returned ore, quicklime and limestone are: iron ore powder 74%, coke powder 3%, returned ore 10%, quicklime 5%, limestone 8%, and the alkalinity of the sintering mixture is 1.9. Coke powder with a particle size of less than 3mm accounts for 78%, with an average particle size of 1.92mm; limestone with a particle size of less than 3mm accounts for 75%, with an average particle size of 1.65mm.

[0039] For the wetting of returning ore fetching water, the mass fraction of returning ore fetching water with a particle size of less than 3mm is 5%, and the mass fraction of returned ore fetching water with a particle size of 3 to 5mm is 4%; The returned ore, coke powder with a particle size of 0-3mm, and limestone with a particle size of less than 3mm were added with water accounting for 80% of the total water addition, and the filling rate of the primary mixer was 18%. After mixing in the primary mixer for 5 minutes, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com