Output-controllable turning knocking heat exchange ash-escaping-prevention type slag granulating and heat energy recycling device

A slag granulation and escape prevention technology, which is applied in recycling technology, waste heat treatment, energy efficiency improvement, etc., can solve the problems of high maintenance cost, complex structure of processing equipment, and low heat energy recovery efficiency, so as to improve the heat energy recovery rate and heat recovery quality, avoidance of slag bonding and controllable output, always the right amount of slag output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

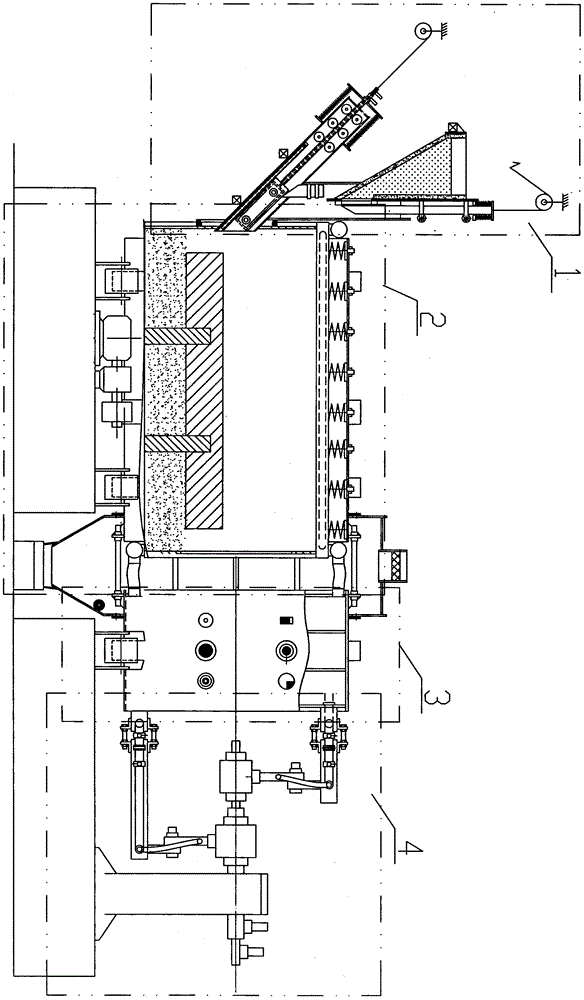

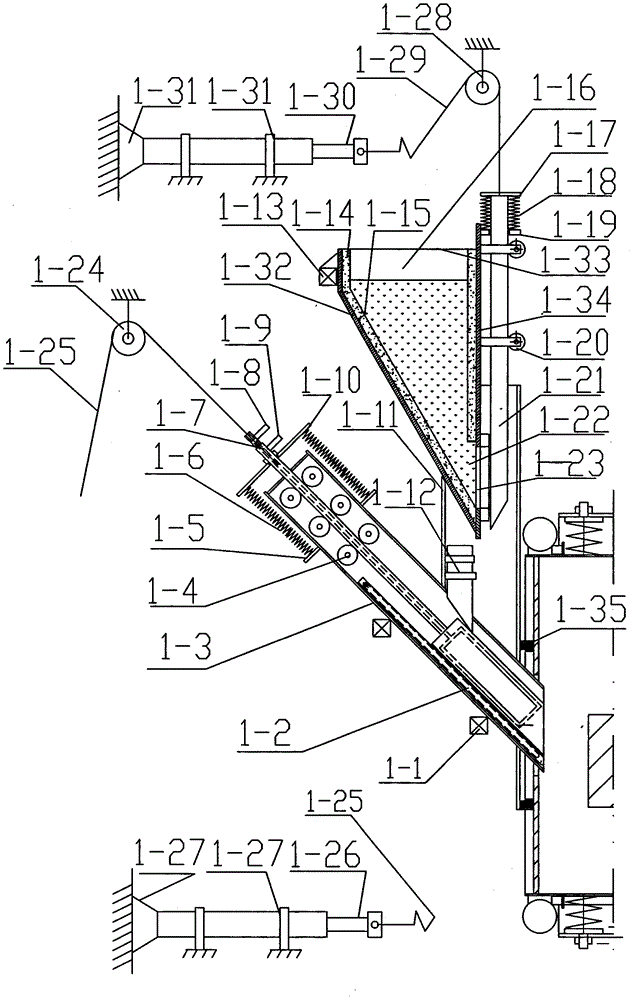

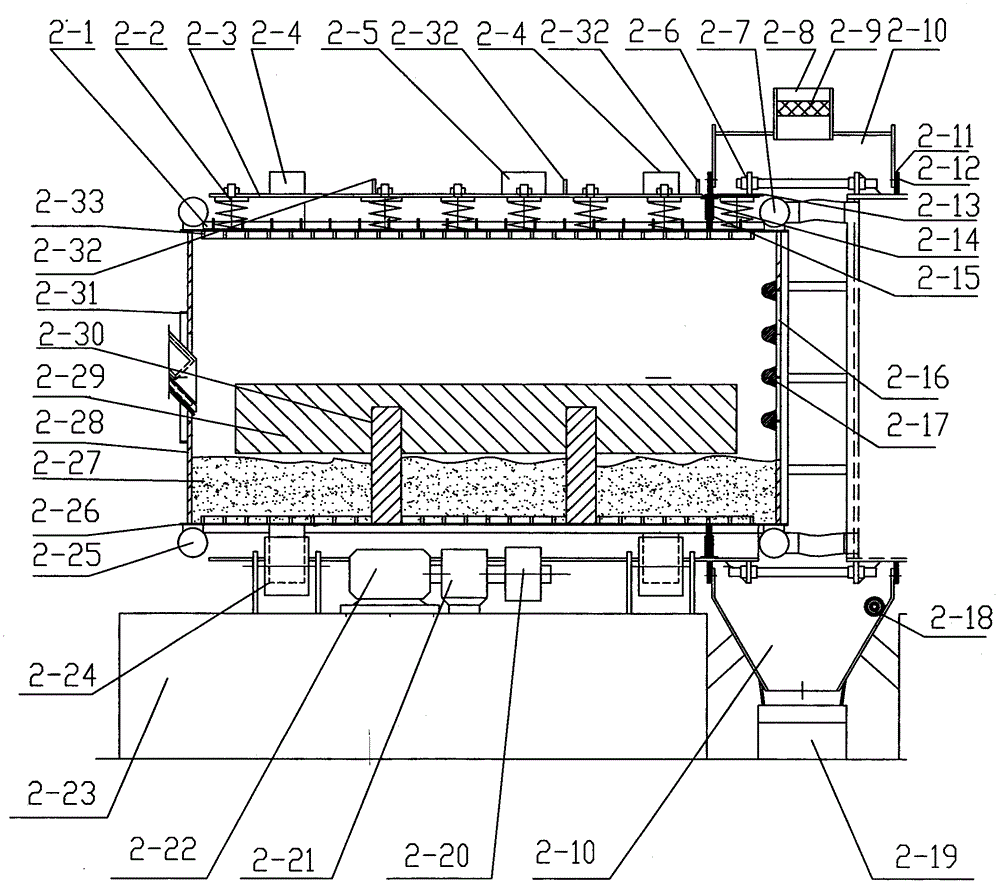

[0044] A kind of device provided by the present invention is further described in conjunction with accompanying drawing as follows:

[0045] 1-0 slag storage and output combination: 1-13 bracket fixes 1-16 inclined cone slag tank support with 1-14 refractory material and 1-15 anchor on the inner surface to the upper left of 2-0; 1-32 The inclined surface of the inclined cone slag tank, the second frame surface of the 1-33 inclined cone slag tank, and the vertical surface of the 1-34 inclined cone slag tank are combined to form a 1-16 inclined cone slag tank slope; the 1-34 inclined cone slag tank The vertical surface is provided with 1-21 steel cutting parts that can move up and down, and the bottom of the surface is provided with 1-23 slag outlet at the bottom of the slag tank; one end of the spring using 1-18 telescopic cutting parts is connected to 1-17 cutting parts to fix the spring The other end is fixed on the steel block of 1-19 fixed spring on the vertical surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com