A treatment method for applying copper smelting waste slag to sintering

A processing method and technology for copper smelting, applied in the fields of metallurgy and material science, can solve the problems of short high temperature holding time of sinter, deterioration of sintering ore-forming conditions, and fast cooling rate of material surface, etc., to promote the formation of microstructure and improve the liquid phase. Production capacity, the effect of increasing the temperature of the material layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

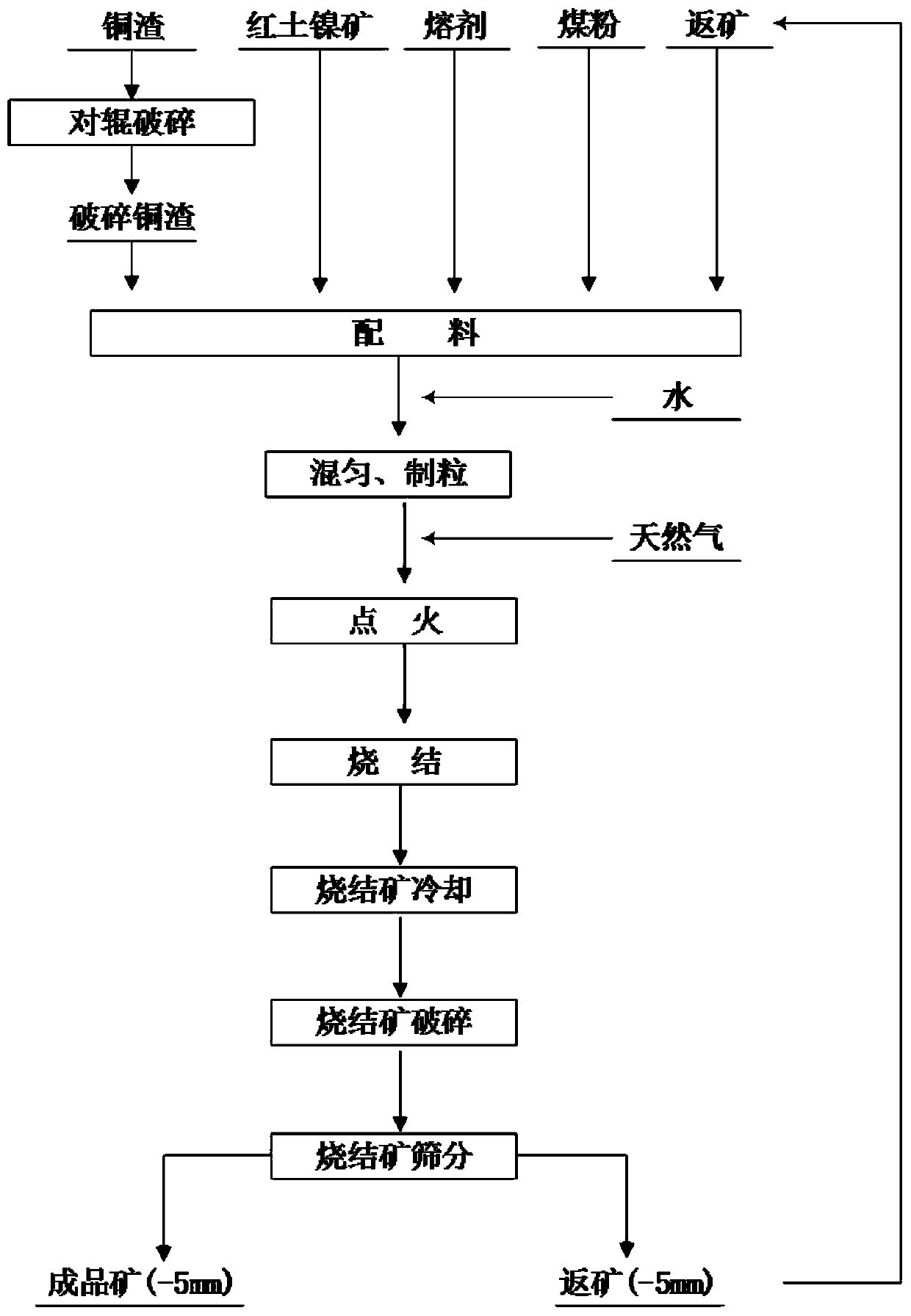

Method used

Image

Examples

Embodiment 1

[0028] (1) Crushing of copper smelting waste residue: get copper smelting waste residue, its main chemical composition is 39.85% TFe (total iron), 0.83wt% Cu, 43.7wt% FeO, 30.81wt% SiO2 . The copper smelting waste slag is crushed into particles whose particle size is 100% less than 5mm and 10% less than 1mm to obtain copper smelting waste slag powder.

[0029] (2) Ingredients: TFe containing 47.4wt%, 0.90wt% Ni, 1.23wt% MgO, 4.83wt% SiO 2 After the laterite nickel ore (37.6wt%) and the copper smelting waste slag powder (9.4wt%) with the LOI value of 13.1wt% are mixed according to the ratio of 8:2, then return ore with 30wt%, 8.0wt% pulverized coal, 5wt% quicklime, 2.5wt% dolomite and 7.5wt% limestone are mixed uniformly to obtain the mixture to be sintered.

[0030] (3) Granulation: add water to the mixture to be sintered, and adjust the moisture content of the mixture to be sintered to 17.0%. Mix in a cylinder mixer, control the speed of the mixer to 30r min -1 , a filling...

Embodiment 2

[0035] (1) Crushing of copper smelting waste residue: get copper smelting waste residue, its main chemical composition is 39.85% TFe, 0.83wt% Cu, 43.7wt% FeO, 30.81wt% SiO 2 . The copper smelting waste slag is crushed into particles whose particle size is 100% less than 5mm and 10% less than 1mm to obtain copper smelting waste slag powder.

[0036] (2) Ingredients: TFe containing 47.4wt%, 0.90wt% Ni, 1.23wt% MgO, 4.83wt% SiO 2 After the laterite nickel ore (32.55wt%) with LOI value 13.1wt% and copper smelting waste slag powder (13.95wt%) are mixed according to the ratio of 7:3, then return ore with 30wt%, 7.5wt% pulverized coal, 5 Quicklime, 2.5wt% dolomite and 8.5wt% limestone are mixed uniformly to obtain a mixture to be sintered.

[0037] (3) Granulation: add water to the mixture to be sintered, and adjust the moisture content of the mixture to be sintered to 16.0%. Mix in a cylinder mixer, control the speed of the mixer to 30r min -1 , a filling rate of 20%, and a gran...

Embodiment 3

[0042] (1) Crushing of copper smelting waste residue: get copper smelting waste residue, its main chemical composition is 39.85% TFe, 0.83wt% Cu, 43.7wt% FeO, 30.81wt% SiO 2 . The copper smelting waste slag is crushed into particles whose particle size is 100% less than 5mm and 10% less than 1mm to obtain copper smelting waste slag powder.

[0043] (2) Ingredients: TFe containing 47.4wt%, 0.90wt% Ni, 1.23wt% MgO, 4.83wt% SiO 2 After the laterite nickel ore (27.6wt%) and copper smelting waste slag powder (18.4wt%) with LOI value of 13.1wt% are mixed according to the ratio of 6:4, then return ore with 30wt%, 7.5wt% pulverized coal, 5wt% quicklime, 2.0wt% dolomite and 9.5wt% limestone are mixed uniformly to obtain the mixture to be sintered.

[0044] (3) Granulation: add water to the mixture to be sintered, adjust the water content of the mixture to be sintered to 16.0%, then mix in a cylinder mixer, control the speed of the mixer to 30r min -1 , a filling rate of 20%, and a g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com