A method for improving the dephosphorization rate of desiliconization furnace based on double converter method for smelting high-silicon hot metal

A furnace dephosphorization rate, high silicon technology, applied in the field of iron and steel smelting, can solve the problems of large splash, heat imbalance, smelting process out of control, etc., achieve the effect of reducing production pressure, reducing losses, and improving desiliconization and dephosphorization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

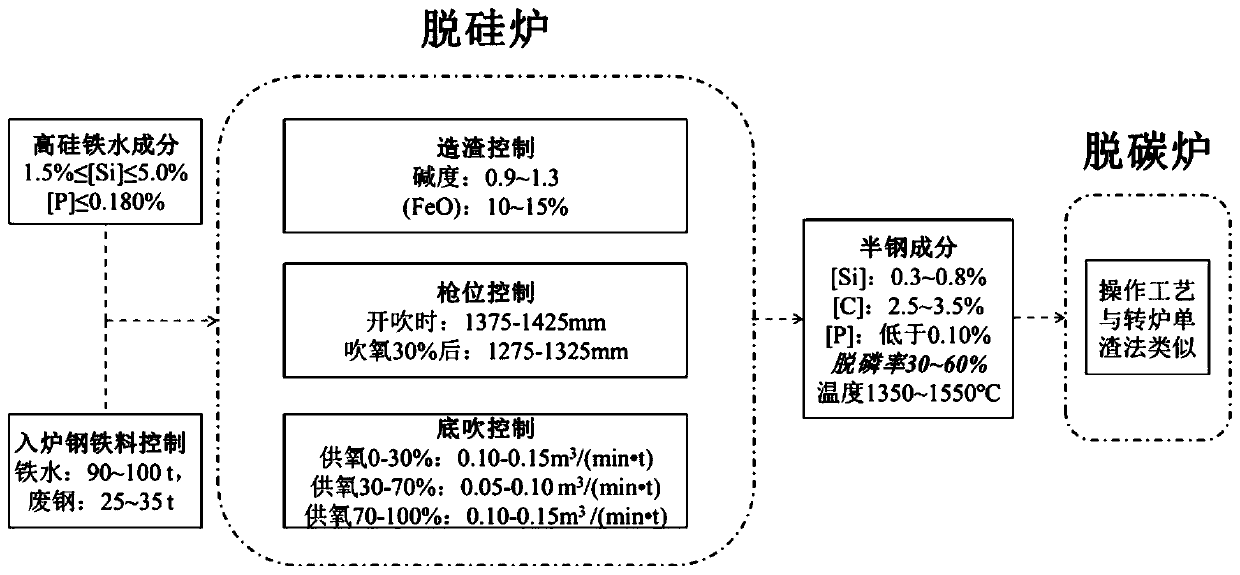

Method used

Image

Examples

Embodiment 1

[0059] The content of molten iron [Si] is 4.00%, the content of molten iron [C] is 4.20%, the content of molten iron [P] is 0.145%, the temperature of molten iron is 1302 ° C, and the operation is carried out by double converter method (desiliconization furnace + decarburization furnace). According to the content of molten iron [Si], the loading amount of molten iron in the desiliconization furnace is set to 95t, the loading amount of scrap steel is 30t, and the oxygen supply is set to 3500Nm 3 o 2 .

[0060] Add 10.23kg / t of lime and 9.50kg / t of dolomite before blowing, add 36.26kg / t of lime, 21.35kg / t of dolomite and 8.15kg / t of iron ore before blowing 30% oxygen. Depending on the smelting situation, 15.12kg / t of lime, 9.12kg / t of dolomite and 7.91kg / t of iron ore are added at about 50% oxygen blowing. The total lime consumption per ton of steel is 61.61kg / t, dolomite consumption is 39.97kg / t, and iron ore consumption is 16.06kg / t. The temperature of the semi-steel is 150...

Embodiment 2

[0069] Compared with Example 1, this experimental example is only different in the silicon content of molten iron, the scrap ratio, the amount of smelting slag added, the tapping temperature, and the carbon and phosphorus content at the end point. The content of molten iron [Si] is 2.30%, the content of molten iron [C] is 4.10%, the content of molten iron [P] is 0.152%, the temperature of molten iron is 1321 °C, and the operation is carried out by a double method (desiliconization furnace + decarburization furnace).

[0070]The [Si] content of molten iron in this heat is 2.30%, so the steel scrap ratio is lower than the setting, the molten iron loading is set to 100t, the scrap loading is 25t, and the oxygen supply is set to 2000Nm 3 o 2 .

[0071] Add 8.11kg / t of lime and 7.50kg / t of dolomite before blowing, and add 24.12kg / t of lime, 15.35kg / t of dolomite and 6.42kg / t of iron ore before blowing 30% oxygen. Depending on the smelting situation, 8.31kg / t of lime, 8.22kg / t of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com