Environment-friendly and efficient bolt coating device for field of steel structure buildings

A coating device and steel structure technology, applied to the device for coating liquid on the surface, the cleaning method using tools, coating, etc., can solve the problems of wasting paint, inefficient coating, environmental pollution, etc., and increase safety Sex, reduce the chance of splashing, increase the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

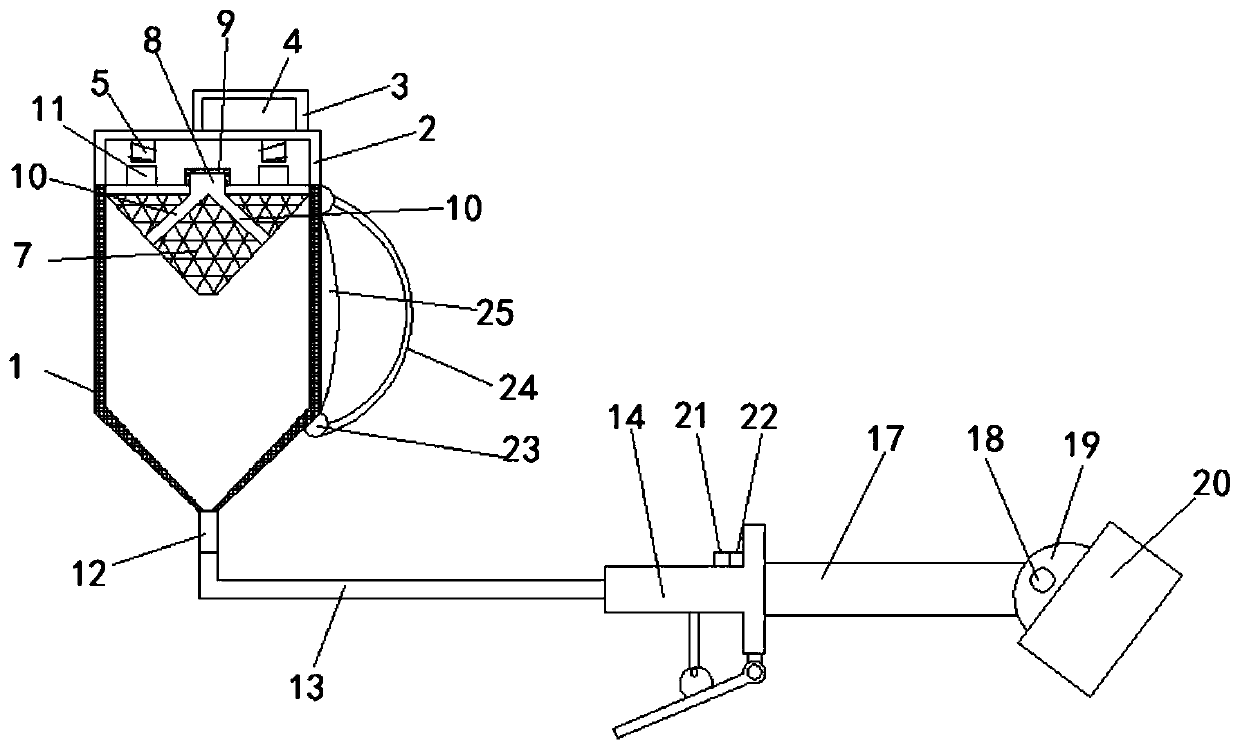

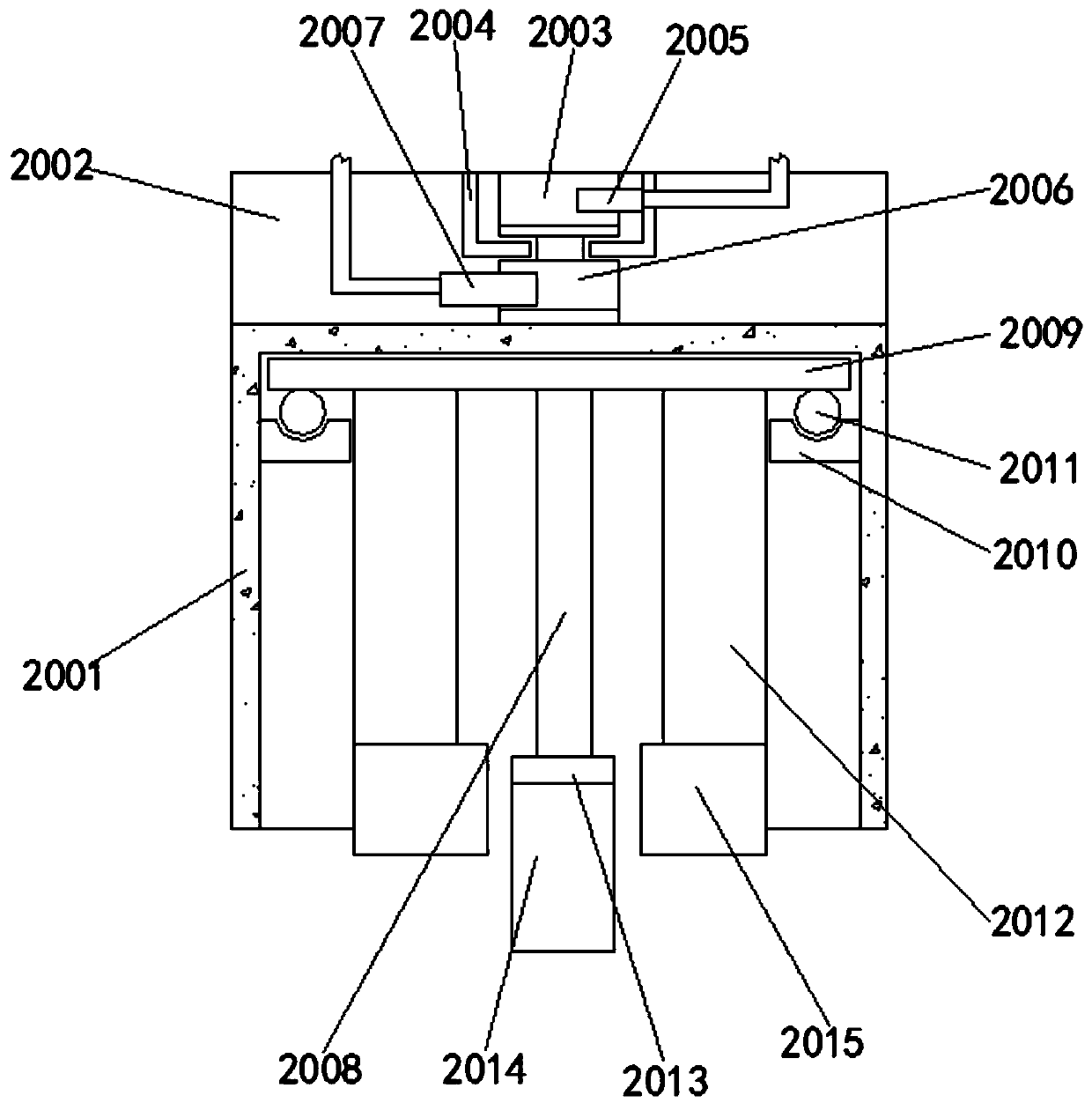

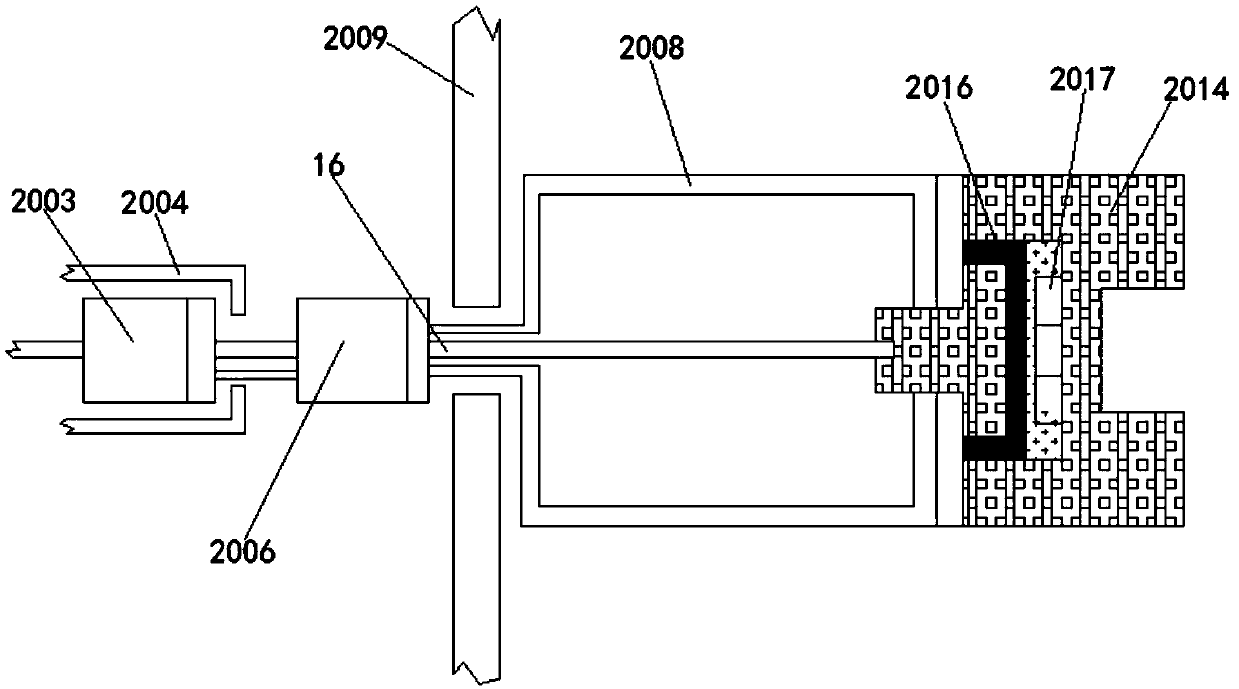

[0035] see Figure 1-6 According to an embodiment of the present invention, an environmentally friendly and efficient bolt coating device used in the field of steel structure construction includes a paint bin 1, a bracket 2 is fixed above the paint bin 1, and a housing is arranged on the bracket 2 3. The casing 3 is equipped with a mobile power supply 4, and the inner wall of the bracket 2 is fixed with a number of winding iron columns 5, and the winding iron columns 5 are electrically connected to the mobile power supply 4. The paint warehouse 1 A piston 7 matching the bottom of the paint bin 1 is provided inside, a feed inlet 8 is provided on the piston 7, a sealing cover 9 is provided on the feed inlet 8, and the feed inlet 8 is located under the The piston 7 is provided with a liquid passage 10 connecting the paint bin 1 and the feed port 8, and the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com