Method for smelting molten iron by using iron ore with high phosphorus and high aluminum oxide

A technology for aluminum oxide and iron ore powder, which is applied in the field of smelting molten iron with high-phosphorus iron ore powder and high-aluminum oxide-containing iron ore powder, can solve the problem that the mineral composition of high-phosphorus iron ore is complex, the industrial production application has not been realized, Reduce the processing capacity of the ball mill and other problems to achieve the effect of improving the fluidity of molten iron, the fluidity of slag, and the fluidity of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment uses high phosphorus, high Al2 o 3 Iron ore powder, using the conventional shaft furnace process to produce molten iron.

[0035] The concrete steps of this embodiment are as follows:

[0036] (1) Iron ore powder pellets:

[0037] High phosphorus, high Al 2 o 3 Iron ore powder is crushed to -3mm by a crusher, then 15% coke powder is added, and it is pressed into a 20-30mm agglomerate by a double roller machine.

[0038] High phosphorus and high Al 2 o 3 In iron ore powder, TFe, FeO, SiO 2 、Al 2 o 3 , CaO, MgO, P, S weight percent: TFe 62.3%; FeO 28.193 SiO 2 5.1%; CaO 0.6%; MgO 0.5%; Al 2 o 3 2.2%; P 0.08%; S 0.027%;

[0039] (2) Burden structure and distribution:

[0040] Mix the prepared mass with coke, limestone, dolomite and add it to the shaft furnace:

[0041] Agglomerate 1538kg Coke 880kg;

[0042] Limestone 256kg; Dolomite 58kg.

[0043] (3) Control operation system

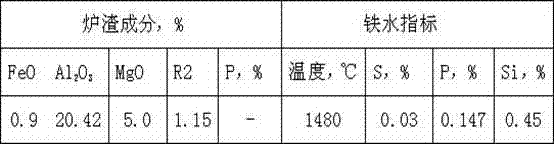

[0044] By adjusting the operating system, the temperature...

Embodiment 2

[0070] The concrete steps of this embodiment are as follows:

[0071] Ⅰ Iron ore powder pelletizing

[0072] Step is with embodiment 1,

[0073] Ⅱ Charge structure and distribution:

[0074] Same as Example 1

[0075] Ⅲ Shaft furnace smelting

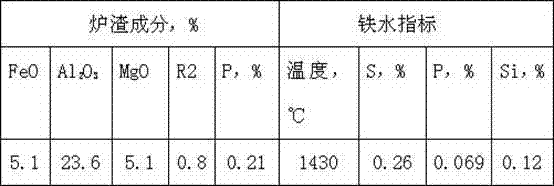

[0076] By adjusting the operating system of the shaft furnace, the content of FeO in the slag is controlled at 5.1%, the binary basicity of the slag is controlled at 0.8, the sulfur content in the molten iron is controlled at 0.26%, the Si content in the molten iron is 0.12%, and the temperature of the molten iron is controlled at 1430°C. The phosphorus content of molten iron is controlled below 0.1%.

[0077] Ⅳ tapping

[0078] After smelting in the shaft furnace, the phosphorus content in the slag is 0.21%, and more than 51% of the phosphorus brought in by the raw materials enters the slag.

[0079] Ⅴ Slagging

[0080] Al in slag 2 o 3 The content is quite high at 23.6%, but the slag has better fluidity. For the convenience...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com