Method for extracting vanadium from solid

A technology of solid and solid powder, applied in the field of vanadium extraction, can solve the problems of environmental hazards, equipment corrosion, high maintenance costs, unusability, etc., and achieve the effect of low vanadium extraction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

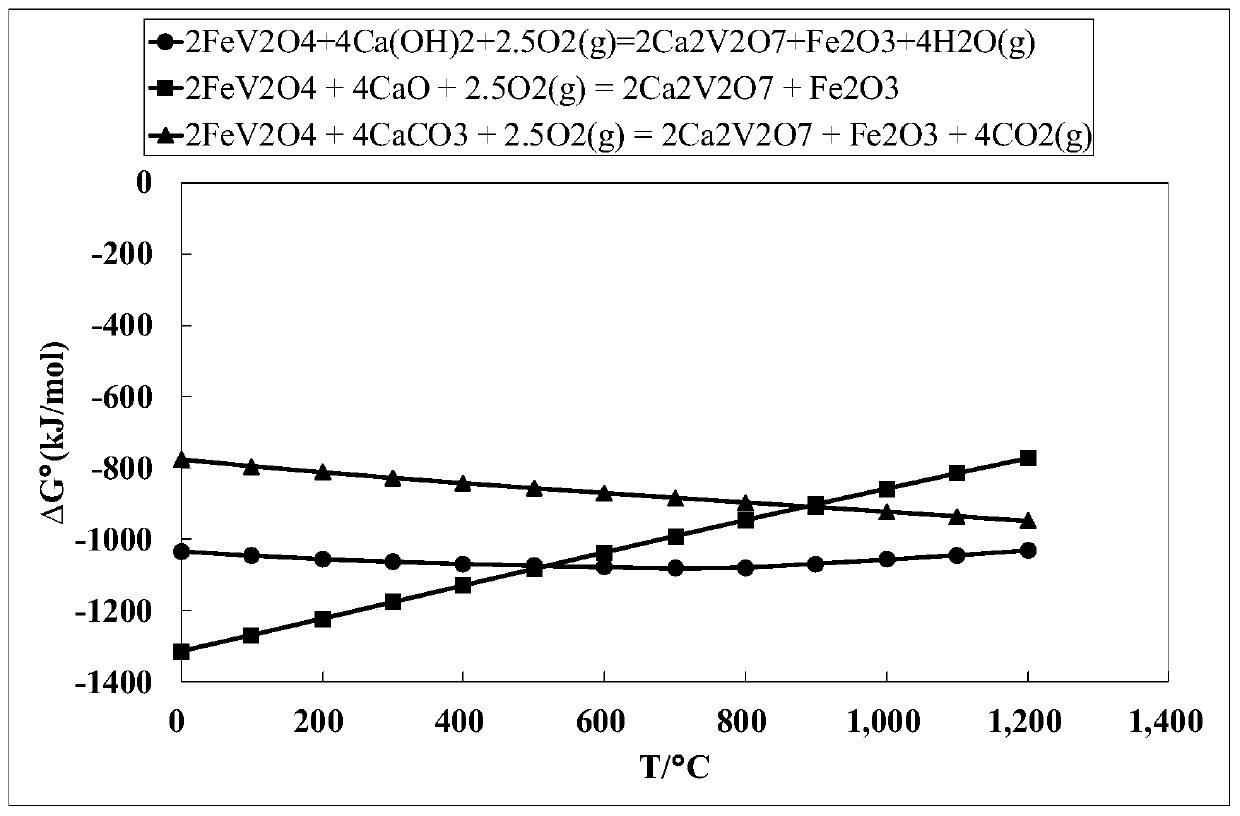

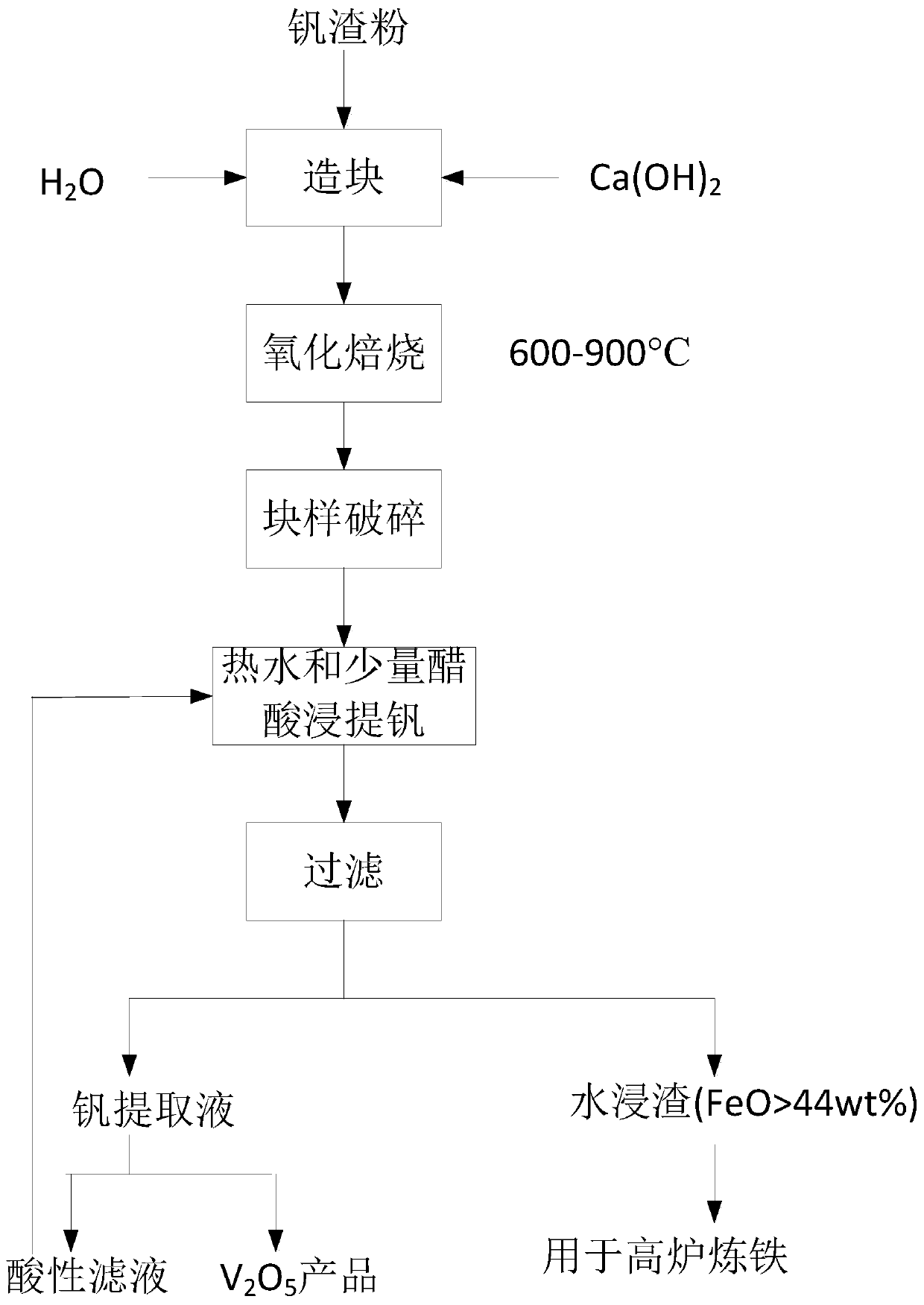

Method used

Image

Examples

Embodiment 1

[0034] With 20 grams of dry vanadium slag powder (particle size is 48-120 micron, V 2 o 3 and Cr 2 o 3 Contents are respectively 13.80wt.% and 3.18wt.%) and 10 grams of calcium hydroxide (Ca(OH) 2 ) powder and 2 grams of water, and press it into 10 cylindrical blocks with a diameter of 15 mm and a height of 10 mm in a press under a pressure of 0.5 MPa. Take 10 block samples and put them into a high aluminum boat. Put the boat in a muffle furnace that has been preheated to 800°C. The furnaces of the muffle furnace are slightly opened. After keeping at this temperature for 2 hours, take out the boat and let it cool naturally in the air. It was found that the roasted block samples in the boat were hard and complete, and the high-alumina boat was not bonded at all. The weight of 10 block samples after roasting was 25.8 grams. Crush 10 roasted samples by hand, then pulverize them with a sample mill, transfer the powder into a 500mL glass beaker, add 250mL deionized water to th...

Embodiment 2

[0036] With 20 grams of dry vanadium slag powder (particle size is 48-120 micron, V 2 o 3 and Cr 2 o 3 Contents are respectively 13.80wt.% and 3.18wt.%) and 10 grams of calcium hydroxide (Ca(OH) 2 ) powder and mix them into a high aluminum boat. Put the boat in a muffle furnace that has been preheated to 800°C. The furnaces of the muffle furnace are slightly opened. After keeping at this temperature for 2 hours, take out the boat and let it cool naturally in the air. It was found that the boat was slightly agglomerated after roasting, but the high-alumina boat was basically not bonded. Crush the sintered sample manually, then pulverize it with a sample mill, transfer the powder into a 500mL glass beaker, add 250mL deionized water to the beaker, cover it, heat the aqueous solution to boil for 30 minutes, cool to 60°C, add 5mL concentrated acetic acid (99wt%), kept at 60°C for 60 minutes, cooled to room temperature and then filtered to obtain filter residue 2 and filtrate 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com