A method for pre-enriching vanadium by gravity separation from vanadium-containing stone coal

A technology of pre-enrichment and vanadium stone, which is applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problem of small processing capacity per unit area of the shaking table, poor adaptability of fine-grained minerals, and influence on the industrial application of the process and other issues, to achieve the effect of easy implementation, low processing cost and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

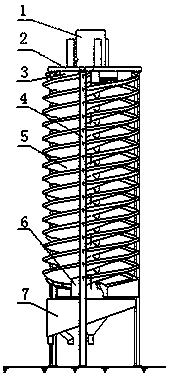

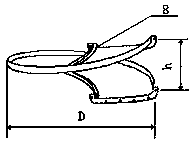

Image

Examples

Embodiment 1

[0033] A method for reselecting and pre-enriching vanadium from vanadium-containing stone coal. The V of the vanadium-containing stone coal described in this embodiment 2 o 5 The grade is 0.50~0.62%. The concrete steps of the method described in this embodiment are:

[0034] (1) Crushing the vanadium-containing stone coal until the particle size is less than 0.074 mm, accounting for 78-90 wt%, to obtain a grinding product; then adjusting the grinding product to a pulp with a concentration of 27-35 wt%, to obtain pulp I.

[0035] (2) Introduce the ore pulp I into "a kind of sulfuric acid slag separation, purification and sorting equipment", adjust the horizontal flushing water flow rate to 34-40L / h, and carry out roughing. The interception point of roughing tailings is 50-60mm, and The interception point of selected ore is 80~92mm, and rougher tailings, concentrate I and rougher ore are obtained respectively.

[0036] (3) Adjust the roughing tailings to a slurry with a conc...

Embodiment 2

[0043]A method for reselecting and pre-enriching vanadium from vanadium-containing stone coal. The V of the vanadium-containing stone coal described in this embodiment 2 o 5 The grade is 0.59~0.71%. The concrete steps of the method described in this embodiment are:

[0044] (1) Crushing the vanadium-containing stone coal until the particle size is less than 0.074 mm, accounting for 64-76 wt%, to obtain a grinding product; then adjusting the grinding product to a pulp with a concentration of 10-18 wt%, to obtain pulp I.

[0045] (2) Introduce the ore pulp I into "a kind of sulfuric acid slag separation, purification and sorting equipment", adjust the horizontal flushing water flow rate to 10-18L / h, and carry out roughing. The interception point of roughing tailings is 42-54mm. The interception point of selected ore is 118~130mm, and rougher tailings, concentrate I and rougher ore are obtained respectively.

[0046] (3) Adjust the roughing tailings to a slurry with a concent...

Embodiment 3

[0054] A method for reselecting and pre-enriching vanadium from vanadium-containing stone coal. The V of the vanadium-containing stone coal described in this embodiment 2 o 5 The grade is 0.69~0.81%. The concrete steps of the method described in this embodiment are:

[0055] (1) Crushing the vanadium-containing stone coal until the particle size is less than 0.074mm, accounting for 50-62wt%, to obtain a grinding product; then adjusting the grinding product to a slurry with a concentration of 14-22wt%, to obtain a slurry I.

[0056] (2) Introduce the ore pulp I into "a kind of sulfuric acid slag separation, purification and sorting equipment", adjust the horizontal flushing water flow rate to 16-24L / h, and carry out roughing. The interception point of roughing tailings is 35-47mm. The intercept point of selected ore is 99~111mm, and rougher tailings, concentrate I and rougher ore are obtained respectively.

[0057] (3) Adjust the roughing tailings to a slurry with a concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com