Splashed slag furnace protection method for vanadium extraction converter

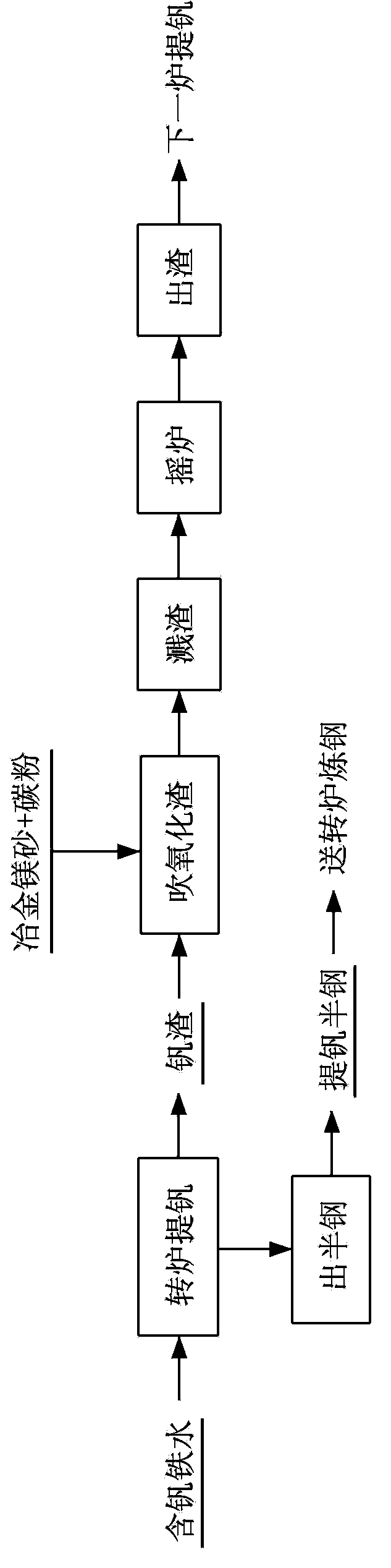

A technology for protecting furnaces and converters by splashing slag, applied in the field of iron and steel metallurgy, can solve the problems of low end temperature and short time of vanadium extraction process, and achieve the effect of simple operation and good furnace protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Mix vanadium-containing molten iron into a 30t converter for vanadium blowing. When the vanadium blowing end point is reached, the semi-steel temperature is 1400°C, and the vanadium-extracted semi-steel is poured out. Then shake the converter to the "zero" position (that is, the converter is not tilted and is in a vertical state), add metallurgical magnesia and carbon powder with a total amount of 2kg / t steel as slag adjustment agent, and blow oxygen slag for 1min to blow the oxidized slag to The slag is uniformly melted to obtain thick vanadium slag, wherein the particle size of the regulator used is below 3.0 mm. After the oxidized slag blowing is completed, switch between oxygen and nitrogen for nitrogen blowing and slag splashing. The working pressure of nitrogen gas for slag splashing is adjusted to 0.8MPa, the distance between the slag splash gun and the furnace bottom is 1000mm, and the slag splashing time is 3.5min. After the thick vanadium slag adheres evenly o...

example 2

[0031] Mix vanadium-containing molten iron into a 120t converter for vanadium blowing. When the vanadium blowing end point is reached, the semi-steel temperature is 1430°C, and the vanadium-extracted semi-steel is poured out. Then shake the converter to the "zero" position, add metallurgical magnesia and carbon powder with a total amount of 3.8kg / t steel as a slag adjustment agent, and pass in oxygen for 2 minutes to blow the oxidized slag until the slag is uniform, and obtain a thick vanadium slag , wherein the particle size of the regulator used is below 3.0mm. After the oxidized slag blowing is completed, switch between oxygen and nitrogen for nitrogen blowing and slag splashing. The working pressure of nitrogen gas for slag splashing is adjusted to 0.9MPa, the distance between the slag splashing gun and the furnace bottom is 1250mm, and the slag splashing time is 3min. After the thick vanadium slag adheres evenly on the furnace lining of the converter, lift the gun and sha...

example 3

[0033]Mix vanadium-containing molten iron into a 200t converter for vanadium blowing. When the vanadium blowing end point is reached, the semi-steel temperature is 1450°C, and the vanadium-extracted semi-steel is poured out. Then shake the converter to the "zero" position, add metallurgical magnesia and carbon powder with a total amount of 5g / t steel as a slag adjustment agent, and pass in oxygen for 3 minutes to blow the oxidized slag until the slag is evenly dissolved, and a thick vanadium slag is obtained. Wherein, the particle size of the regulator used is below 3.0 mm. After the oxidized slag blowing is completed, switch between oxygen and nitrogen for nitrogen blowing and slag splashing. The working pressure of nitrogen gas for slag splashing is adjusted to 1.0MPa, the distance between the slag splash gun and the furnace bottom is 1500mm, and the slag splashing time is 4min. After the thick vanadium slag adheres evenly on the furnace lining of the converter, lift the gun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com