A method for improving vanadium grade in vanadium concentrate by oxidation treatment-magnetic separation

A magnetic separation and oxidation treatment technology, applied in magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of scattered distribution, low grade, complex process, etc., and achieve the goal of reducing the cost of vanadium extraction and reducing the amount of treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The implementation steps of the method described in this embodiment are:

[0021] (1) the vanadium concentrate obtained is crushed and screened to a particle size less than 0.074mm, to obtain a grinding product I;

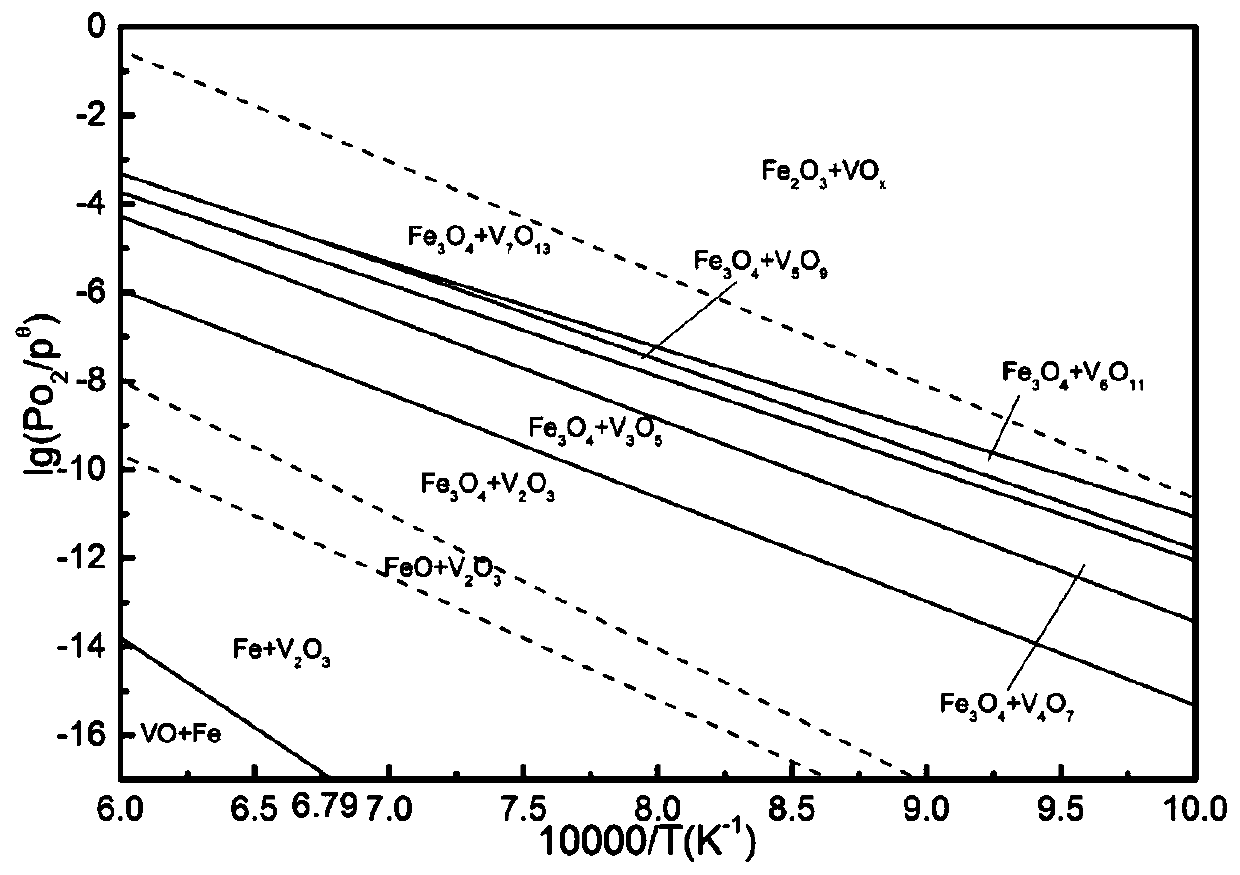

[0022] (2) Put an appropriate amount of grinding product I into an alumina crucible, and place it in a high temperature reaction furnace at 900°C, CO / CO 2 Carry out calcination under the atmosphere of =1.2, and the calcination time is 1 hour to obtain calcined product II;

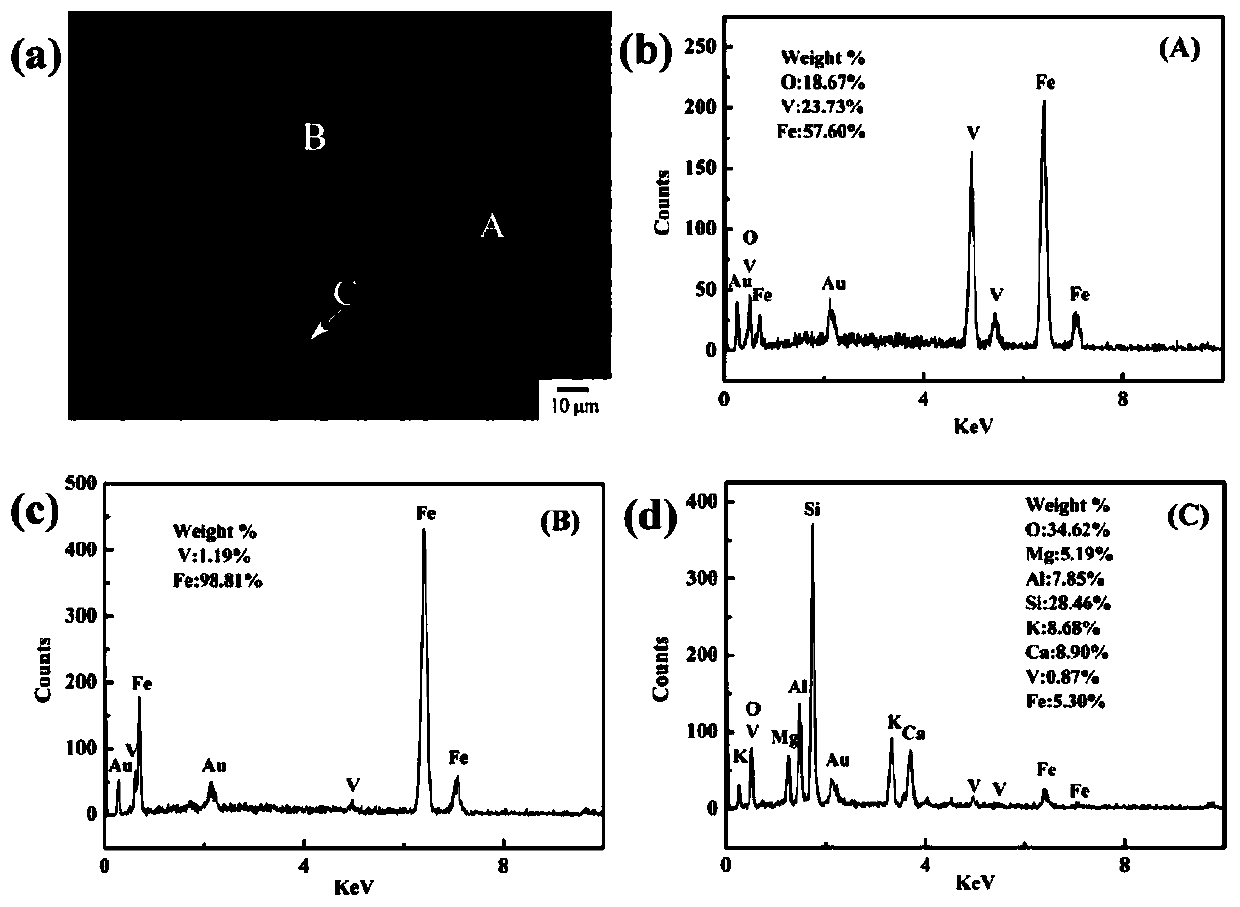

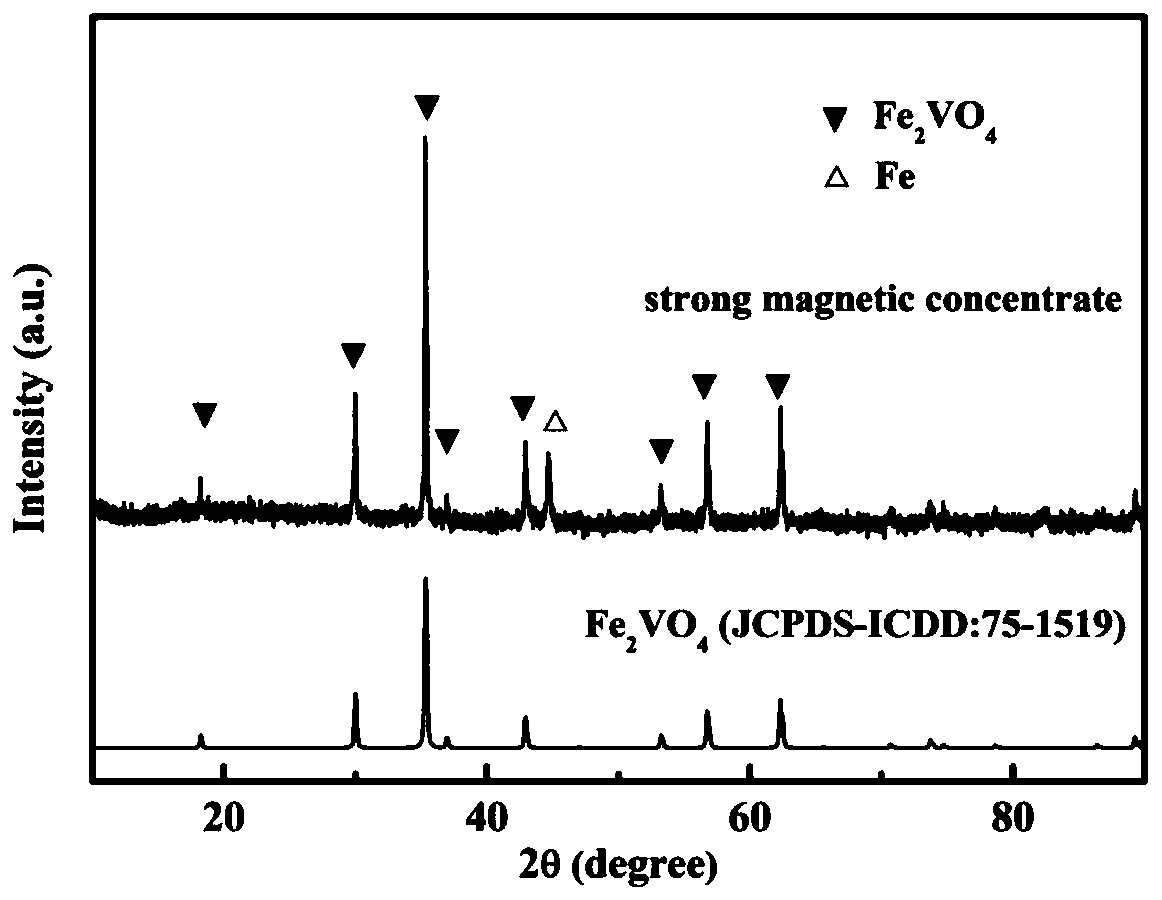

[0023] (3) The calcined product II obtained above is continuously crushed and sieved to a particle size of less than 0.074 mm, mixed with deionized water to make ore pulp, and subjected to magnetic separation in a 0.35 T magnetic field. The strong magnetic samples after magnetic separation are filtered, removed and dried to obtain vanadium concentrate products; the weak magnetic samples separated by magnetic separation are filtered and dried, and can be added to the vanadium-containing s...

Embodiment 2

[0026] The implementation steps of the method described in this embodiment are:

[0027] (1) the vanadium concentrate obtained is crushed and screened to a particle size less than 0.074mm, to obtain a grinding product I;

[0028] (2) Put an appropriate amount of grinding product I into an alumina crucible, and place it in a high-temperature reaction furnace at 1000°C, CO / CO 2 Carry out calcination under the atmosphere of = 1.5, the calcination time is 1 hour, obtain calcined product II;

[0029] (3) The calcined product II obtained above is continuously crushed and sieved to a particle size of less than 0.074 mm, mixed with deionized water to make ore pulp, and subjected to magnetic separation in a 0.35 T magnetic field. The strong magnetic samples after magnetic separation are filtered, impurity removal and drying to obtain vanadium concentrate products; the weak magnetic samples separated by magnetic separation are filtered and dried, and can be added to vanadium-containing...

Embodiment 3

[0032] The implementation steps of the method described in this embodiment are:

[0033] (1) the vanadium concentrate obtained is crushed and screened to a particle size less than 0.074mm, to obtain a grinding product I;

[0034] (2) Put an appropriate amount of grinding product I into an alumina crucible, and place it in a high temperature reaction furnace at 1100°C, CO / CO 2Carry out calcination under the atmosphere of = 2.0, the calcination time is 1 hour, obtain calcined product II;

[0035] (3) The calcined product II obtained above is continuously crushed and sieved to a particle size of less than 0.074 mm, mixed with deionized water to make ore pulp, and subjected to magnetic separation in a 0.35 T magnetic field. The strong magnetic samples after magnetic separation are filtered, impurity removal and drying to obtain vanadium concentrate products; the weak magnetic samples separated by magnetic separation are filtered and dried, and can be added to vanadium-containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com