Method for granulating sinter mixture

A technology for sintering mixtures and mixtures, which is applied in furnaces, blast furnace details, blast furnaces, etc., can solve problems such as poor air permeability of sintering material layer and difficulty in granulating sintering mixtures, so as to improve particle size composition and granulation performance, and improve mineral Composition and structure, ability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This example is used to illustrate the granulation method of the sintered mixture provided by the present invention.

[0026]One-time mixing: 4 kilograms of quicklime (with a CaO content of 84% by weight) and 2 kilograms of water are digested for 5 minutes and mixed with 2 kilograms of iron-containing miscellaneous materials (gas ash, particle size is less than 5mm, and iron content is 36% by weight), 15 Kilograms of returned ore (sintered ore, particle size less than 5mm, iron content of 49% by weight), 40kg of rich ore powder (Panzhihua vanadium titanomagnetite concentrate, iron content of 54% by weight, particle size less than 0.074mm) and 2.9 kg The coke powder (the carbon content is 82% by weight) is mechanically stirred in a primary mixer, and mixed uniformly to obtain the first mixture;

[0027] Secondary mixing: 40 kilograms of rich ore powder (Panzhihua vanadium titanomagnetite concentrate, iron content is 54% by weight, particle size is 0.074-1.5mm) and 1.0 ki...

Embodiment 2

[0029] This example is used to illustrate the granulation method of the sintered mixture provided by the present invention.

[0030] One-time mixing: 3 kilograms of quicklime (with a CaO content of 84 wt %) plus 1.5 kilograms of water digested for 5 minutes and 2 kilograms of iron-containing miscellaneous materials (steel slag, particle size less than 5 mm, iron content of 36 wt %), 14 kilograms The returned ore (sintered ore, the particle size is less than 5mm, the iron content is 49% by weight), 20 kg of rich ore powder (Panzhihua vanadium titanomagnetite concentrate, the iron content is 54% by weight, the particle size is less than 0.074mm) and 2.9 kg of The anthracite powder (carbon content is 80% by weight) is mechanically stirred in a primary mixer to be uniformly mixed to obtain a first mixture;

[0031] Secondary mixing: 60 kilograms of rich ore powder (Panzhihua vanadium titano-magnetite concentrate, iron content is 54% by weight, particle size is less than 1.5mm, whe...

Embodiment 3

[0033] This example is used to illustrate the granulation method of the sintered mixture provided by the present invention.

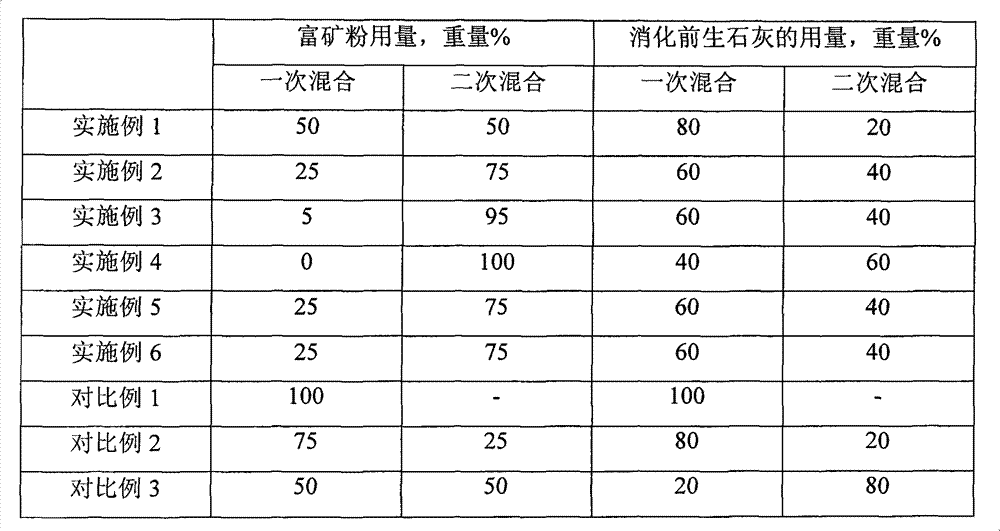

[0034] The granulation is made according to the method of Example 2, the difference is that the first mixed material and the second mixed material are respectively prepared according to the dosage ratio of the rich mineral powder given in Table 1 during the primary mixing and the secondary mixing, and in the first mixed material The weight of the rich ore powder is 4 kilograms (the particle size is less than 0.074mm), and the weight of the rich ore powder in the second mixture is 76 kilograms (the particle size is greater than 0 to less than or equal to 1.5mm, wherein the content of the particle size less than 0.074mm is 47 weights) %, the particle size is 0.074-1.5mm and the particle size content is 53% by weight).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com