Pusher-type heating furnace for rod and wire production line hot transporting and hot charging and direct rolling

A heating furnace and production line technology, applied in the field of industrial furnaces, can solve the problems of hot delivery, hot charging and direct rolling billet transportation, etc., and achieve the effects of facilitating connection and matching, improving productivity, saving equipment investment and floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

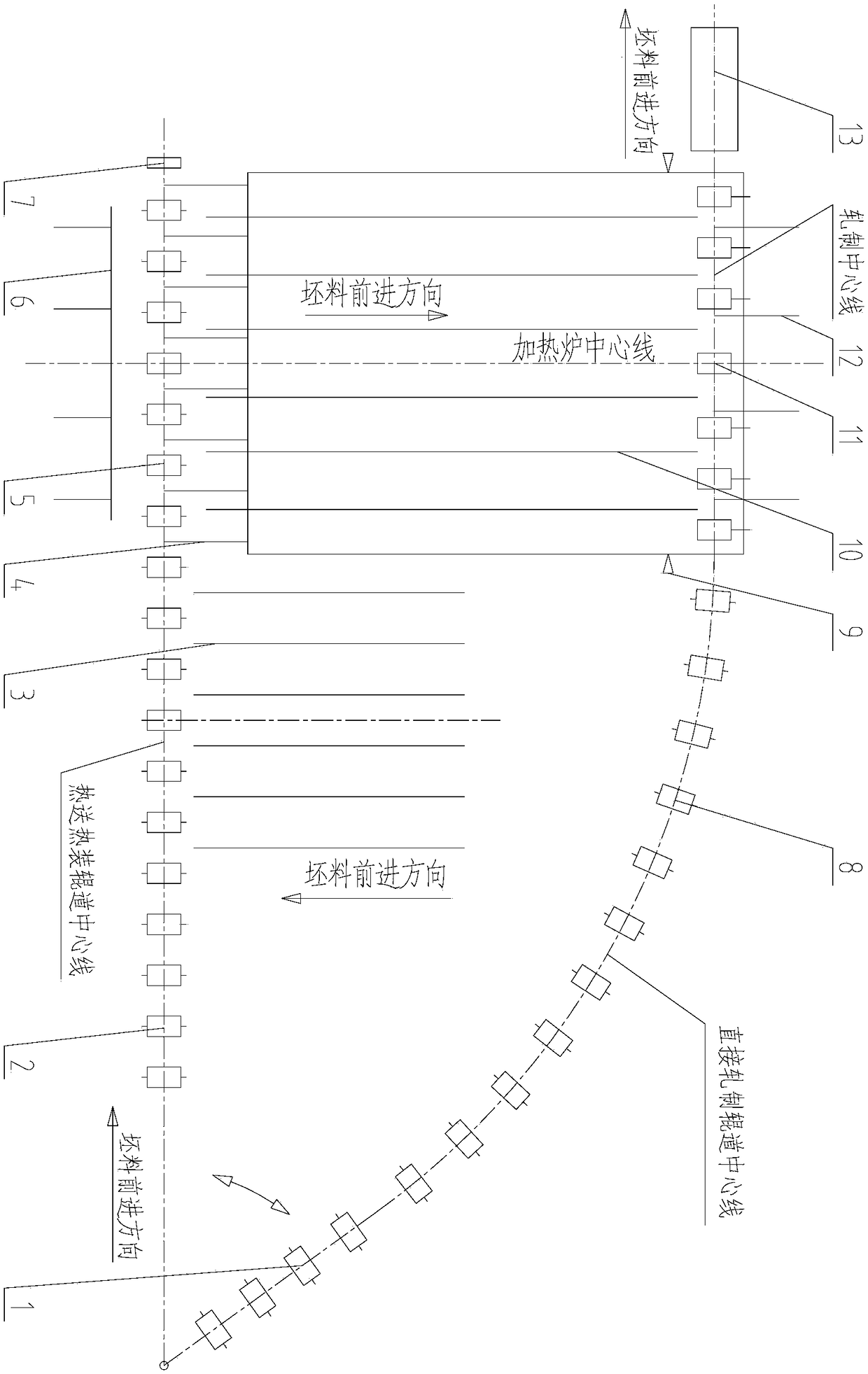

[0021] A pusher-type heating furnace suitable for hot delivery, hot charging and direct rolling of a rod and wire production line, including: swing roller table 1, hot delivery roller table 2, cold billet stand 3, transition stand 4, furnace front roller table 5. Steel pusher 6, buffer baffle 7, arc heat preservation roller table 8, laser detection device 9, furnace bottom beam 10, discharge cantilever roller table 11, steel taking device 12, electromagnetic induction furnace 13; swing roller table 1 Swing between the hot delivery roller table 2 and the arc heat preservation roller table 8, and connect with the hot delivery roller table 2 and the arc heat preservation roller table 8 respectively; the center line of the hot delivery roller table 2 is parallel to the rolling center line, and The center line of the heating furnace is vertical; the cold billet stand 3 is arranged between the hot delivery roller table 2 and the arc-shaped heat preservation roller table 8, and is ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com