A tunnel kiln for ceramic products

A tunnel kiln and product technology, applied in the field of tunnel kiln, can solve problems such as temperature deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

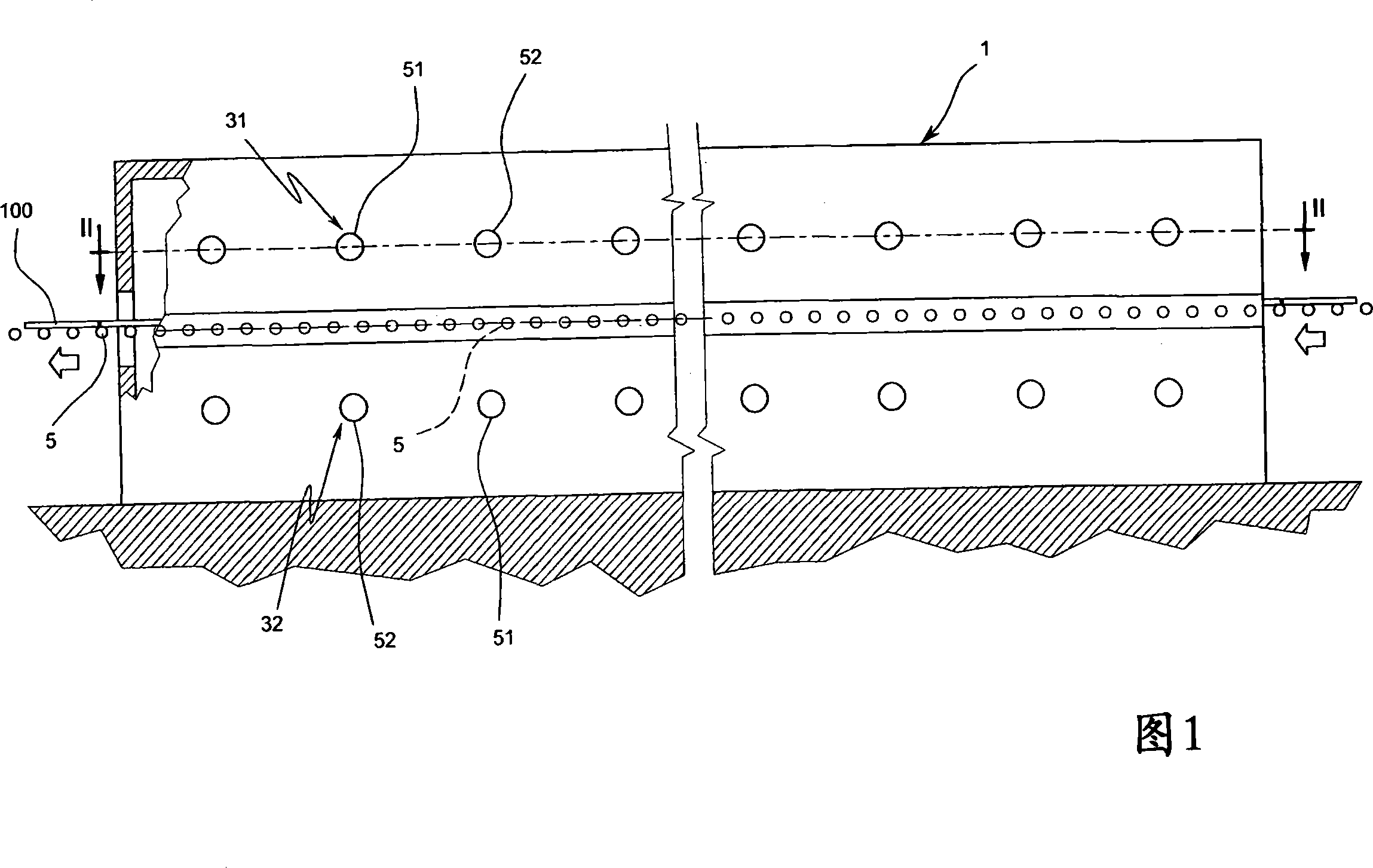

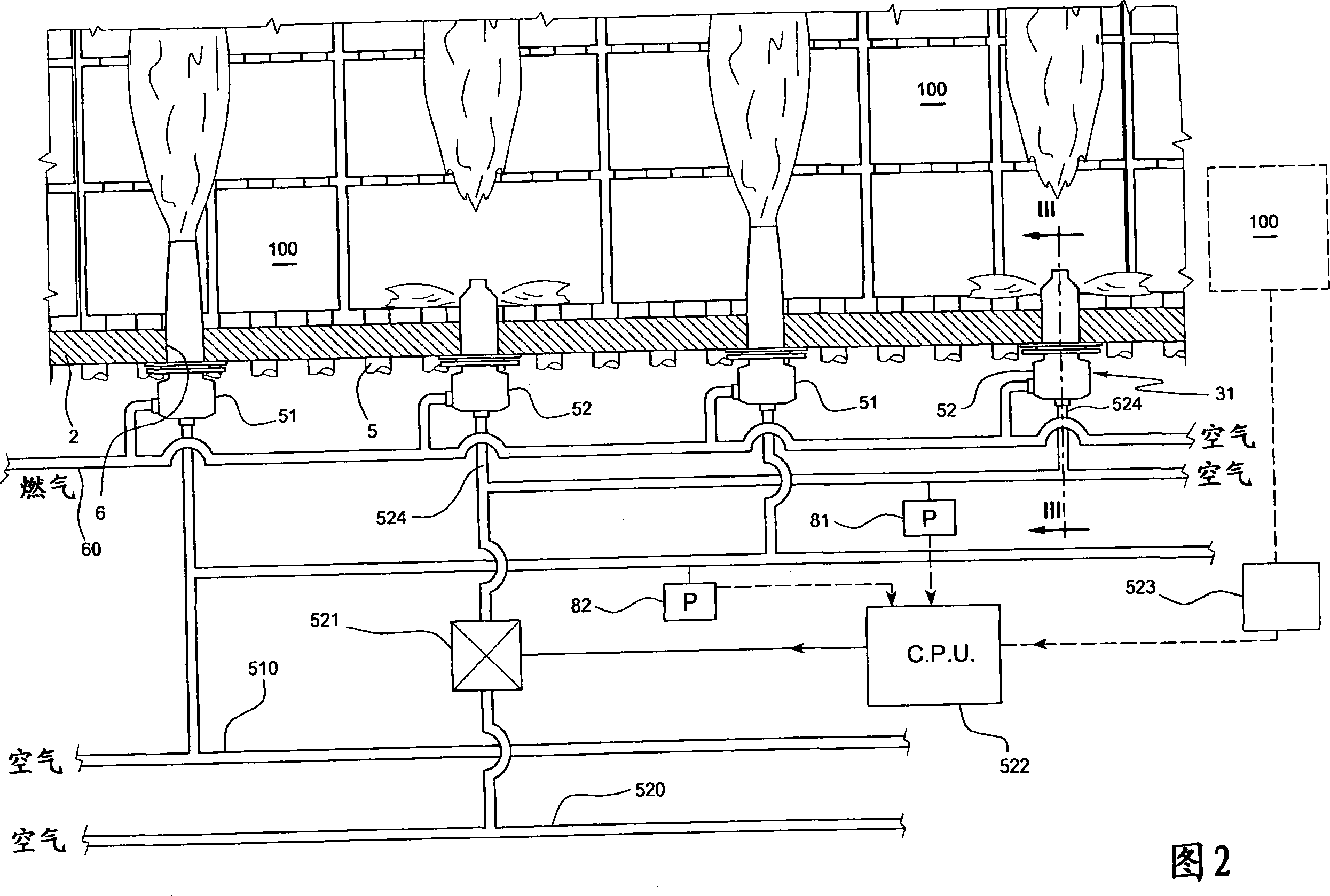

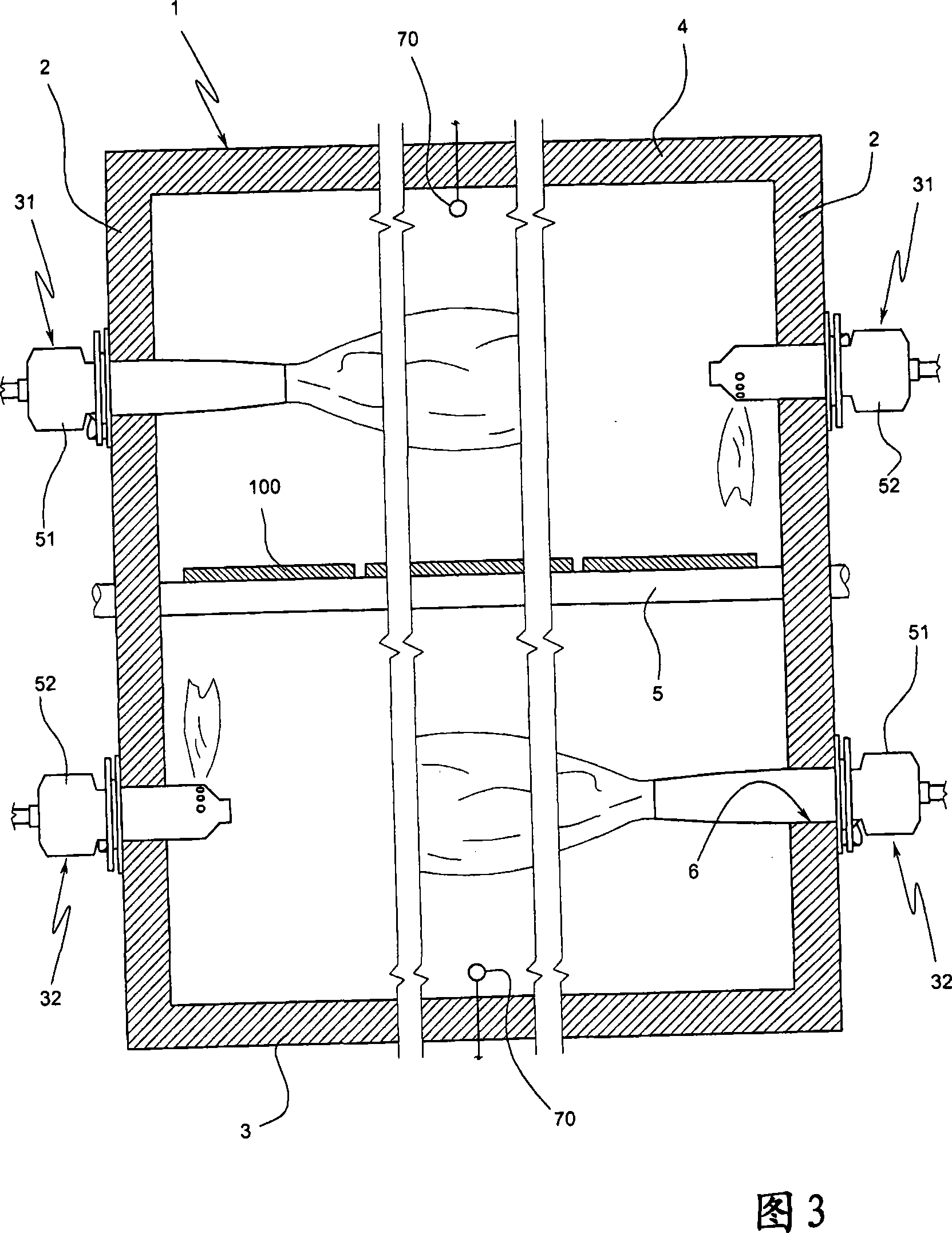

[0024] Referring to the above-mentioned accompanying drawings, among the figure 1 represents the whole of the tunnel kiln for ceramic products according to the present invention.

[0025] According to a very general description, the kiln 1 consists of two opposing side walls 2 , a kiln floor 3 and a kiln roof 4 .

[0026] A roller conveyor 5 of known type is provided inside the kiln 1 , which advances the ceramic product, in the embodiment described a ceramic tile 100 .

[0027] Two rows of gas burners 31 and 32 are arranged on each side wall 2 of the tunnel, respectively above and below the roller conveyor 5 .

[0028] Each row of burners is arranged inside a hole 6 formed in the side wall 2 of the kiln 1 .

[0029] Each row of burners consists of two different series of burners, 51 and 52 respectively, the burners of one series being alternately arranged with the burners of the other series.

[0030] Thus, there are four rows of burners 31, 32, two rows on one side wall an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com