Anti-reflection device for an injection valve and injection valve

An anti-reflection and injection valve technology, used in fuel injection devices, special fuel injection devices, charging systems, etc., can solve problems such as pressure pulsation and fuel volume cannot be properly controlled, and achieve the effect of low hydraulic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

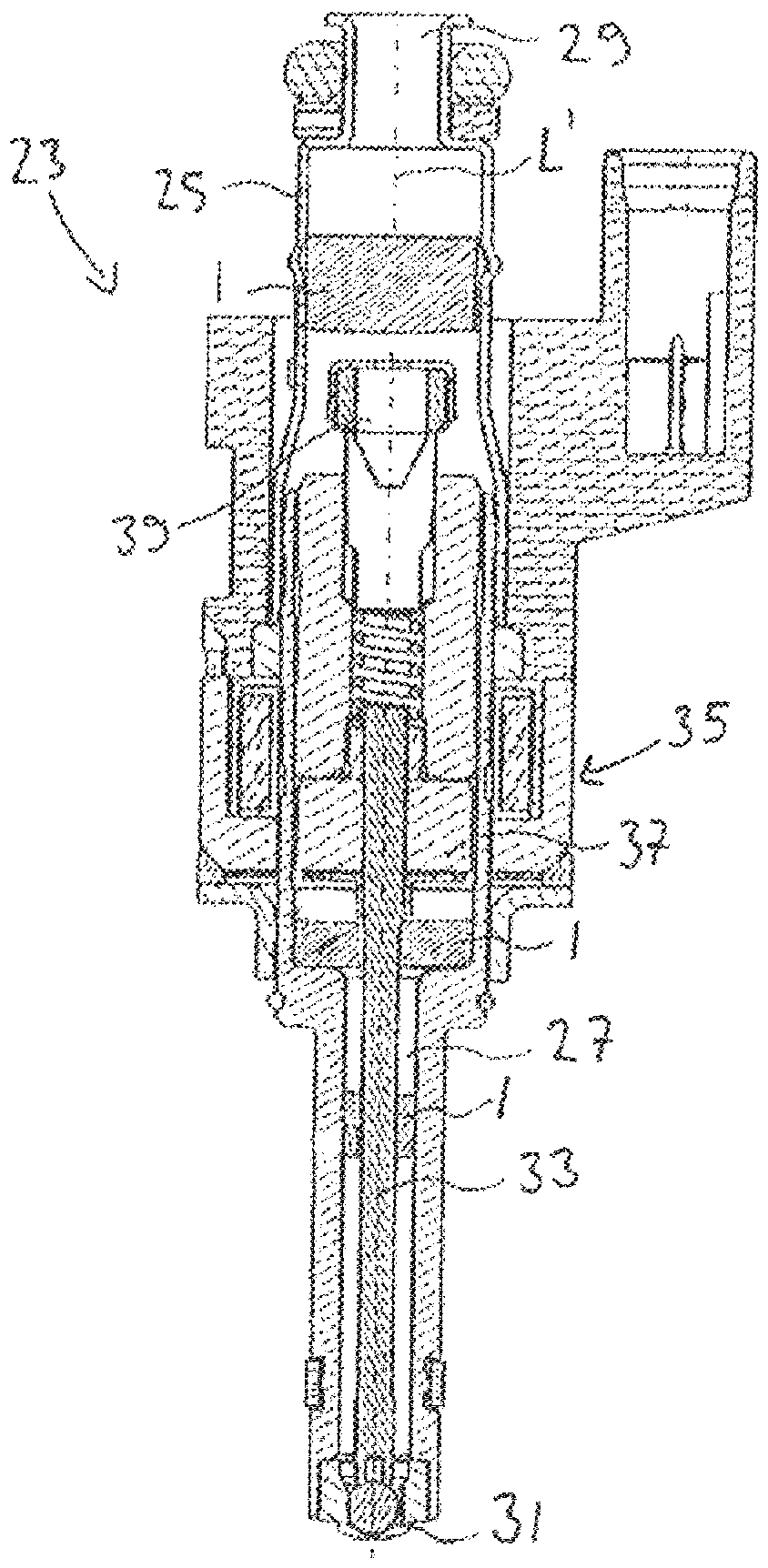

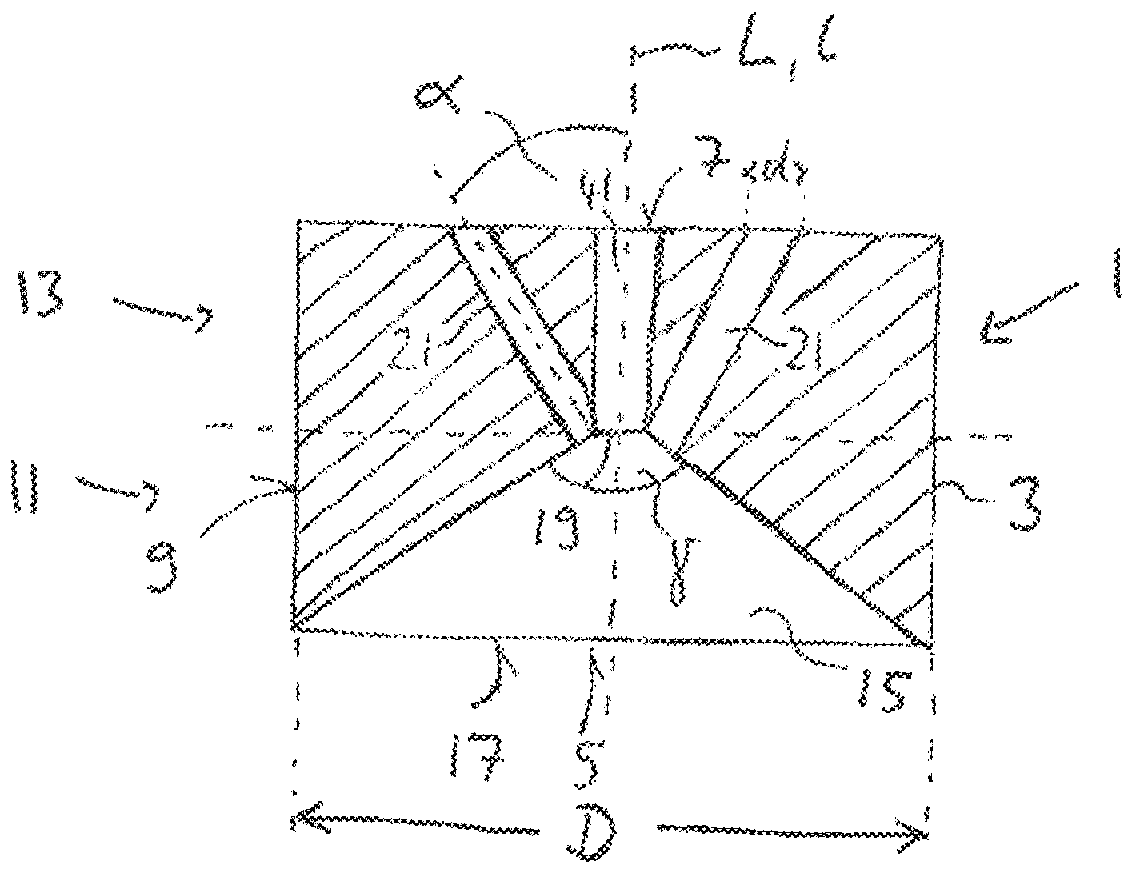

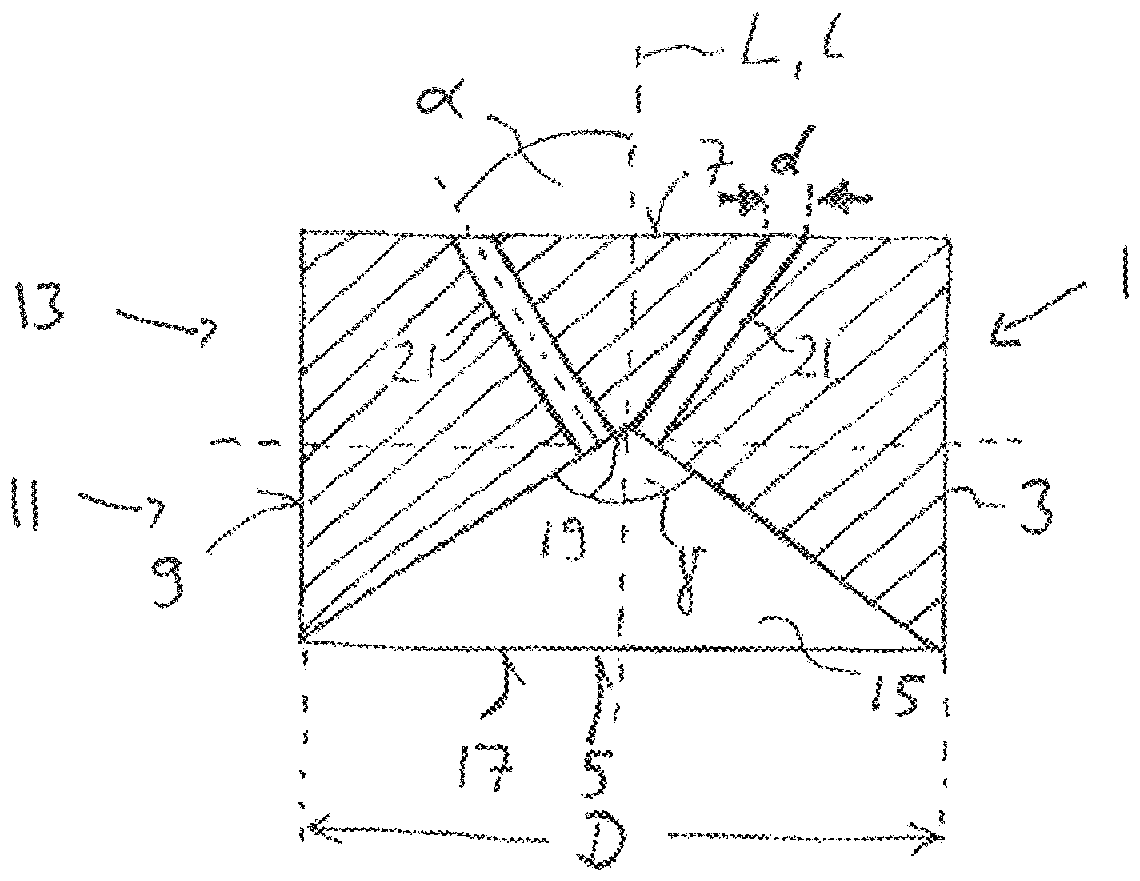

[0030] according to figure 1 The antireflection device 1 has a cylindrical base body 3 with a first base side 5 , a second base side 7 and a peripheral outer surface 9 . The longitudinal axis of the device 1 is denoted L.

[0031] The device 1 comprises two sections, a first section 11 and a second section 13 . The first section 11 extends from the first base side 5 to the central region of the base body 3 . The second section 13 extends from the second base side 7 to the central region of the base body 3 . The first section 11 and the second section 13 can overlap in the central region of the base body 3 .

[0032] Each section provides a hydraulic passage for fluid to flow through the device 1 .

[0033] The first section 11 comprises a chamber in the shape of a hollow cone 15 . The cone 15 has a base side 17 that is coplanar with the first base side 5 and is also part of the first base side 15 . In this embodiment, the longitudinal axis 1 of the cone 15 is identical t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com