Resonator structure and method of producing it

一种谐振器、反射器的技术,应用在电气元件、阻抗网络等方向,能够解决损失等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] Best Mode for Carrying Out the Invention

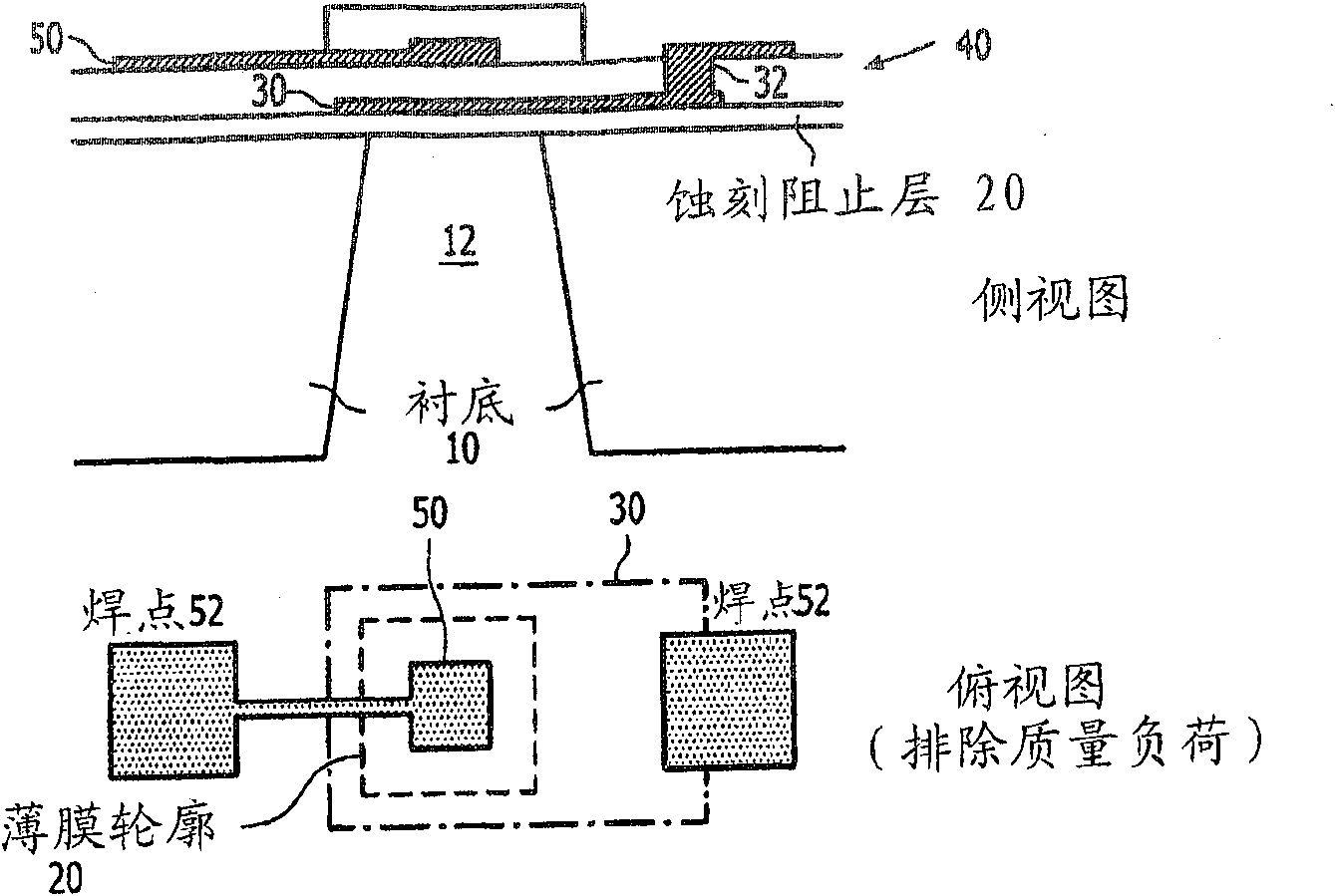

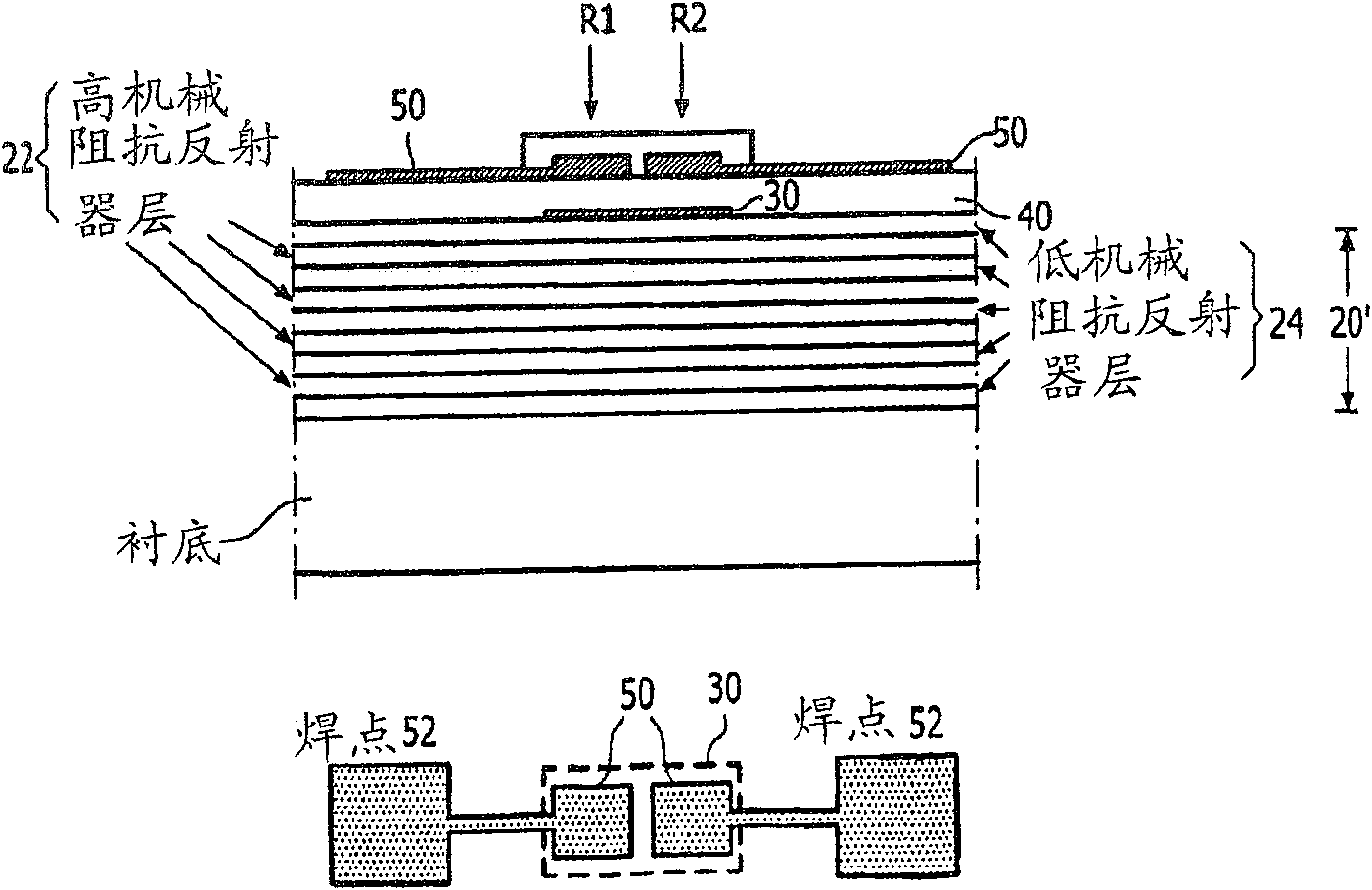

[0087] In what follows, some examples of bulk acoustic wave (BAW) resonators 100, 100' are described by using the planarization proposal according to the present invention; in particular, in Figure 8 Eight different embodiments of the invention are shown in Figure 15C, produced as proposed by the method according to the invention:

[0088] The substrate 10 may be, for example, silicon (Si), glass, gallium arsenide (GaAs), or ceramics.

[0089] On the substrate 10 is coated or deposited an acoustic reflector 20 consisting of fE / 4 layer pairs with high and low acoustic impedance. The layer can be silicon dioxide / tantalum pentoxide (SiO 2 / Ta 2 o 5 ), silicon dioxide / tungsten (SiO 2 / W), silicon dioxide / aluminum nitride (SiO 2 / AlN), silicon dioxide / hafnium dioxide (SiO 2 / HfO 2 ), silicon dioxide / molybdenum (SiO 2 / Mo), silicon dioxide / platinum (SiO 2 / Pt). Instead of silicon dioxide (SiO 2 ), low-density materials s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com